Understanding the proper use and maintenance of your equipment is essential for ensuring its longevity and optimal performance. This guide is designed to provide clear and practical insights into the essential functions, settings, and best practices. By familiarizing yourself with the key features, you’ll be able to get the most out of your machine, avoiding common issues and ensuring a smooth operation.

Maintenance and regular inspections play a crucial role in the long-term performance of your machinery. By following the guidelines laid out in this resource, you’ll learn how to efficiently care for your equipment, troubleshoot potential problems, and handle adjustments with confidence. The aim is to support you in keeping everything running smoothly, minimizing downtime, and maximizing productivity.

Understanding JD 1025R Controls

Operating a compact machine efficiently requires familiarity with its key functions. The design of this model’s interface allows for smooth navigation, helping users perform tasks with confidence. This section covers the primary mechanisms that ensure ease of use in a variety of operations.

Steering and Maneuvering are central to controlling the machine. Clear indicators make it simple to adjust directions and manage speed, ensuring safe movement in different environments. Familiarity with the steering elements will significantly enhance operational efficiency.

Hydraulic and attachment controls are another crucial aspect. These enable the operator to manage connected implements with precision, whether lifting or moving heavy loads. Understanding how to adjust these settings is vital for maximizing the machine’s potential in various tasks.

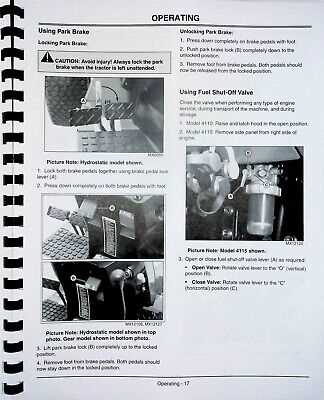

Maintenance Tips for JD 1025R

Proper upkeep is essential to ensure the longevity and performance of your equipment. Regular attention to key components can prevent unexpected issues and extend the lifespan of the machine. By following a consistent schedule, you can keep it operating smoothly in a variety of conditions.

First, focus on checking fluid levels and replacing them as necessary. This includes both engine oil and hydraulic fluids. Clean filters also play a crucial role, so make sure they are inspected and replaced periodically. Keeping moving parts lubricated can reduce wear and enhance overall functionality.

Additionally, inspecting tires for wear and maintaining proper pressure can improve both performance and safety. Regularly tightening bolts and connections ensures the stability of the equipment during operation. Lastly, seasonal inspections and adjustments tailored to specific weather conditions can keep it working efficiently year-round.

Best Practices for Efficient Operation

When it comes to getting the most out of your equipment, understanding the key techniques for smooth and productive functionality is essential. This section outlines several important strategies to help ensure that your machinery operates at its best, reducing wear and tear while optimizing performance.

| Tip | Description |

|---|---|

| Regular Maintenance | Perform routine inspections and necessary upkeep to ensure longevity and prevent malfunctions. |

| Proper Load Management | Avoid overloading the equipment, which can lead to inefficiency and potential damage. |

| Correct Speeds | Operate at recommended speeds to balance power and fuel efficiency. |

| Consistent Fluid Checks | Monitor and replenish fluids to maintain optimal hydraulic and engine performance. |