Maintaining equipment in optimal working condition is crucial for ensuring its long-term performance and reliability. This section delves into the essential practices for keeping your machinery in top shape, offering detailed instructions that cover various aspects of operation and upkeep. With proper attention to key components and regular inspections, you can significantly extend the lifespan of your machine and prevent unexpected breakdowns.

In this guide, you’ll discover step-by-step explanations on how to handle routine check-ups, troubleshoot common issues, and perform necessary adjustments. Whether you’re familiar with similar machines or just getting started, the information provided will help you navigate the processes with confidence. Paying attention to these aspects will allow you to enhance efficiency while reducing the risk of potential malfunctions.

Understanding the Maintenance Requirements of Cub Cadet 1000

Proper care is essential to ensure the longevity and efficient operation of any outdoor power equipment. Regular upkeep not only extends the life of the machine but also helps maintain optimal performance. Following a consistent routine will minimize the risk of unexpected breakdowns and improve overall reliability.

Routine Inspection and Cleaning

A crucial part of maintaining any equipment is inspecting it before and after use. This involves checking key components, such as the air filter, blades, and tires, for wear and damage. Regular cleaning of the deck and engine area helps prevent debris buildup, which can impact performance. Ensuring that all moving parts are free from dirt and grime is essential to avoid premature wear.

Lubrication and Fluid Levels

Keeping the machine properly lubricated is vital for its smooth operation. Apply grease to all the

Key Tips for Prolonging Your Equipment’s Lifespan

Proper care and maintenance are essential to ensure your machinery functions smoothly for an extended period. By adhering to a few key practices, you can help reduce wear and tear, minimize downtime, and avoid costly repairs. These steps will not only improve overall performance but also extend the operational life of your equipment.

Regular Maintenance Checks

Frequent inspections are crucial for detecting any potential issues before they escalate. Pay attention to the condition of key components like filters, belts, and oil levels. Keeping these in optimal shape will help prevent mechanical breakdowns. It’s advisable to establish a maintenance schedule that includes tasks such as cleaning, lubricating moving parts, and replacing worn-out elements.

Proper Storage and Handling

Correct storage conditions can significantly impact the longevity of your machinery. Store it in a dry,

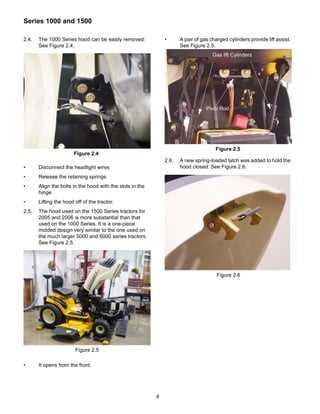

Troubleshooting Common Issues with Series 1000 Models

Over time, all mechanical equipment can experience certain operational difficulties. Identifying and resolving these issues quickly can help maintain the performance and extend the life of your machinery. Below are some of the most frequent problems encountered, along with practical solutions to address them effectively.

Engine Won’t Start

If your machine fails to start, the issue might stem from several potential causes. First, ensure that the fuel tank is filled and that the fuel is fresh. Old fuel can lead to poor engine performance. Additionally, check the battery charge and connections, making sure there is no corrosion on the terminals. If the problem persists, inspect the spark plug for wear or damage, as a faulty spark plug can prevent ignition.

Uneven Cutting

For uneven grass cuts, the cutting blades could be dull or damaged. Sharpen or replace them

Quick Fixes and Expert Advice for Smooth Operation

Ensuring optimal performance of your machine involves addressing common issues and following expert recommendations. Regular upkeep and prompt attention to minor problems can help you avoid costly repairs and downtime.

Battery care: If you experience difficulties with starting, it might be due to battery issues. Check the connections, clean any corrosion, and ensure it’s fully charged. A weak or discharged battery often leads to ignition problems.

Blade maintenance: For clean and effective cutting, it’s essential to keep the blades sharp. Dull or damaged edges can cause uneven cutting, stressing the engine. Sharpen the blades periodically and replace them when necessary.

Engine troubleshooting: If the motor runs unevenly or stalls, verify the fuel and air filters. A clogged filter restricts airflow, leading to poor combustion. Regularly inspect and replace filters as part of your maintenance routine.

Drive belt inspection: A worn or loose drive belt can affect power transmission, resulting in reduced efficiency. Inspect the belt for wear and adjust or replace it when needed to maintain smooth operation.

Safety Guidelines for Operating Tractors

Ensuring proper operation of tractors is crucial for maintaining safety during all tasks. Following recommended precautions helps avoid accidents and extends the life of the equipment. By adhering to these guidelines, users can work more efficiently and with confidence.

Pre-Operation Inspection: Always check the machine for any visible issues before starting. Ensure that all parts are in good condition, fluids are at the correct levels, and there are no signs of wear or damage. This practice helps prevent malfunctions during use.

Operator Awareness: Stay alert and focused when using the tractor. Keep distractions to a minimum and be aware of your surroundings, including any obstacles or bystanders. If you’re unsure about