In the world of material handling, having a reliable and efficient lift truck is crucial for maximizing productivity and ensuring safety in various operations. Understanding the intricacies of your lift vehicle can significantly enhance its performance and longevity. This section aims to provide essential insights into the features, maintenance, and operational guidelines for optimal use.

By familiarizing yourself with the specific functionalities and capabilities of your equipment, you can make informed decisions regarding its daily operation and upkeep. Proper care not only extends the lifespan of the machine but also minimizes the risk of unexpected breakdowns. As you delve into this guide, you will find valuable information tailored to enhance your experience and proficiency with your forklift.

Furthermore, this resource is designed to assist users in troubleshooting common issues, understanding safety protocols, and maximizing the machine’s efficiency. Whether you are a seasoned operator or a newcomer, this guide serves as a valuable reference to support your journey in mastering the art of lift truck management.

Understanding the Toyota 8FGU25 Features

This section aims to explore the various attributes and functionalities that enhance performance and usability. Recognizing the key components can significantly improve the user experience and operational efficiency of the equipment.

Key Attributes

- Robust Engine: The powerful engine ensures reliable performance under various load conditions.

- Efficient Fuel Consumption: Designed for optimal fuel efficiency, contributing to cost savings.

- Advanced Safety Features: Equipped with multiple safety systems to protect both the operator and the equipment.

- Ergonomic Design: Focuses on user comfort, minimizing operator fatigue during extended use.

Functional Capabilities

- Versatile Lifting Capacity: Capable of handling a wide range of loads, making it suitable for diverse applications.

- Smooth Maneuverability: Designed for easy navigation in tight spaces, enhancing productivity.

- Durability: Constructed with high-quality materials to withstand harsh working environments.

- Intuitive Controls: User-friendly interface for easier operation and reduced training time.

Maintenance Tips for Optimal Performance

Regular upkeep is essential for ensuring that your equipment operates efficiently and reliably. Implementing effective maintenance practices not only prolongs the lifespan of your machinery but also enhances its performance. Below are key recommendations to help you maintain optimal functionality.

Routine Inspections

Conduct frequent evaluations to identify any potential issues early on. Check for leaks, unusual noises, and any signs of wear and tear. Keeping an eye on these factors can prevent more significant problems down the line.

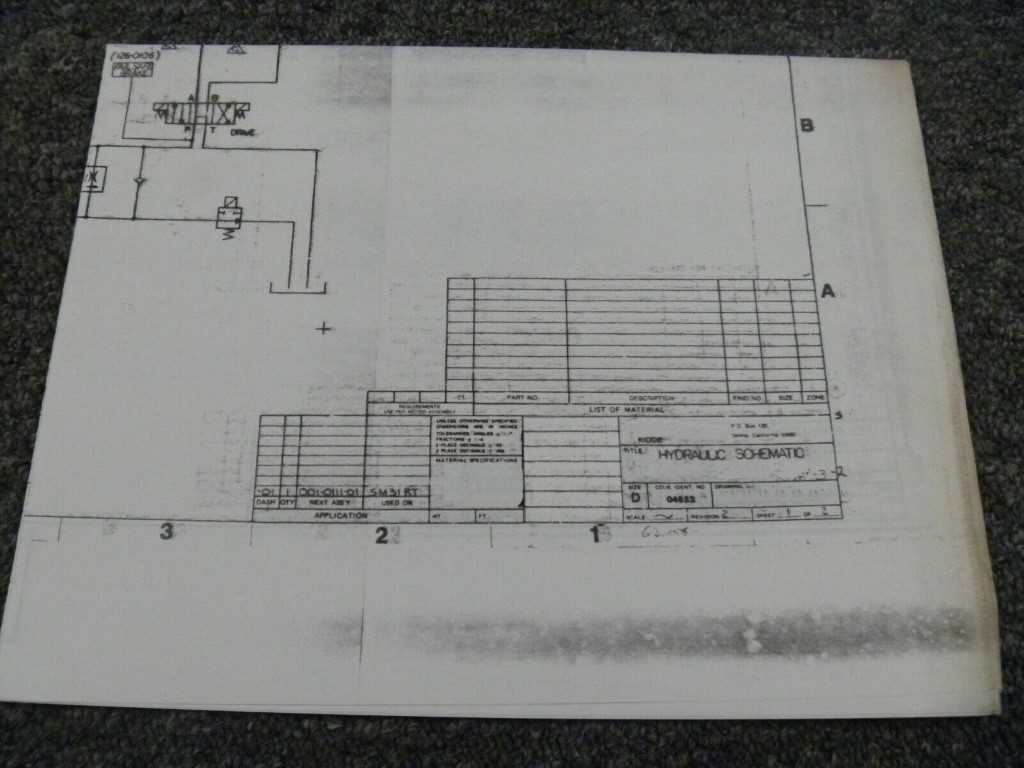

Fluid Levels and Quality

Ensure that all fluid levels, including hydraulic fluid and engine oil, are within the recommended ranges. Regularly change fluids according to the manufacturer’s guidelines to maintain performance. Clean and replace filters as needed to ensure proper circulation and efficiency.

Remember: Consistent care is the key to reliable operation and can save you from costly repairs in the future.

Safety Guidelines for Operators

Ensuring a safe working environment is crucial for all operators handling industrial equipment. Adhering to specific safety protocols not only protects individuals but also enhances overall operational efficiency. This section outlines essential practices and precautions that should be followed to maintain safety while operating machinery.

Operators should familiarize themselves with the equipment and its components before use. Understanding the functionality and limitations of the machinery is fundamental to preventing accidents and ensuring a smooth operation.

| Guideline | Description |

|---|---|

| Wear Protective Gear | Always use appropriate personal protective equipment such as helmets, gloves, and safety shoes to minimize the risk of injuries. |

| Inspect Equipment Regularly | Conduct thorough inspections before each use to identify any potential issues that may compromise safety. |

| Follow Operating Procedures | Adhere to established operating procedures and manufacturer recommendations to ensure safe and effective use of the machinery. |

| Stay Alert | Maintain focus and awareness of your surroundings while operating to quickly react to any hazards or emergencies. |

| Report Unsafe Conditions | Immediately report any unsafe conditions or equipment malfunctions to a supervisor to facilitate prompt resolution. |

By implementing these safety guidelines, operators can significantly reduce the risk of accidents and create a safer working environment for themselves and their colleagues.