In the realm of outdoor machinery, understanding the intricacies of your equipment is crucial for optimal performance and longevity. This segment aims to provide essential insights and practical advice, enabling users to navigate their devices effectively. Proper handling not only enhances functionality but also ensures safety during operation.

Equipped with the right information, users can maximize the capabilities of their equipment while minimizing potential issues. This includes familiarizing oneself with operational guidelines, maintenance routines, and troubleshooting strategies. Such knowledge empowers individuals to maintain their devices in peak condition, ensuring they remain reliable tools for various tasks.

Moreover, knowing the specifications and features of your machinery enhances user confidence and efficiency. This resource serves as a comprehensive reference, offering detailed instructions and valuable tips to address common concerns. With this guidance, you can fully harness the potential of your equipment, transforming it into a dependable ally for your outdoor projects.

Understanding Your Yamaha Pressure Washer

This section provides an overview of essential aspects related to your cleaning equipment. Grasping the key components and functions can significantly enhance your experience and efficiency while using this device. Familiarity with the design and operation of this tool will ensure optimal performance and longevity.

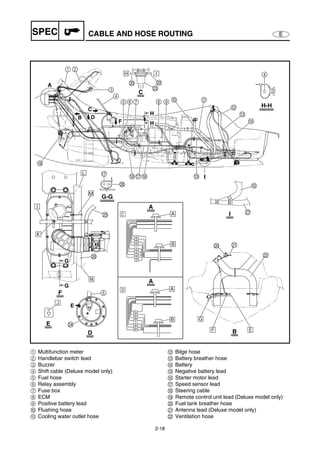

Below are the main components that you should be aware of:

- Motor: The powerhouse of your equipment, responsible for generating the necessary force for effective cleaning.

- Pump: This part is crucial as it pressurizes the water, allowing for a powerful spray that removes dirt and grime.

- Nozzles: Different attachments that adjust the spray pattern and intensity, providing versatility for various cleaning tasks.

- Hose: A durable line that delivers the water from the unit to the nozzle, often resistant to kinks and abrasions.

- Wheels: Designed for mobility, allowing you to easily transport your unit across different surfaces.

Understanding these elements will enable you to operate your device safely and effectively. Consider consulting the accompanying documentation for further insights on maintenance and troubleshooting.

Maintenance Tips for Longevity

Proper upkeep is essential for extending the lifespan and ensuring optimal performance of your equipment. Regular attention to maintenance tasks not only enhances efficiency but also prevents costly repairs in the future. Implementing a consistent care routine can significantly contribute to the longevity of your machine.

Regular Cleaning

Keeping your equipment clean is crucial. After each use, ensure that all components are free of debris and contaminants. Pay special attention to filters and nozzles, as any blockage can hinder functionality.

Routine Inspections

Conducting routine inspections helps identify potential issues before they escalate. Check hoses, connectors, and other critical parts for signs of wear or damage. Early detection can save time and money in repairs.

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Clean filters and nozzles | After each use | Ensures optimal flow and performance |

| Inspect hoses and connections | Monthly | Look for cracks or leaks |

| Check oil levels | Every 25 hours of use | Maintain proper lubrication |

| Store in a dry place | Always | Prevents rust and damage |

Common Issues and Troubleshooting Guide

This section provides insights into frequent challenges that users may encounter with their cleaning equipment, along with practical solutions to resolve these issues. Understanding these common problems can enhance the overall experience and ensure optimal functionality.

Frequent Problems and Solutions

| Issue | Possible Causes | Suggested Solutions |

|---|---|---|

| Unit won’t start | Dead battery, faulty ignition switch, or blocked fuel line | Check battery charge, replace ignition switch, or clear fuel line obstructions |

| Inconsistent performance | Dirty air filter, clogged nozzle, or low fuel | Clean or replace air filter, unclog nozzle, or refill fuel tank |

| Overheating | Insufficient ventilation, prolonged use, or low coolant level | Ensure adequate airflow, take breaks during use, or replenish coolant |

| Unusual noises | Loose parts, damaged components, or low lubrication | Tighten loose parts, inspect for damage, or apply appropriate lubricant |

Maintenance Tips

Regular maintenance is key to preventing many issues. Ensure to clean filters, check fluid levels, and inspect hoses and connections periodically. Following these maintenance steps can prolong the lifespan of the device and minimize unexpected malfunctions.