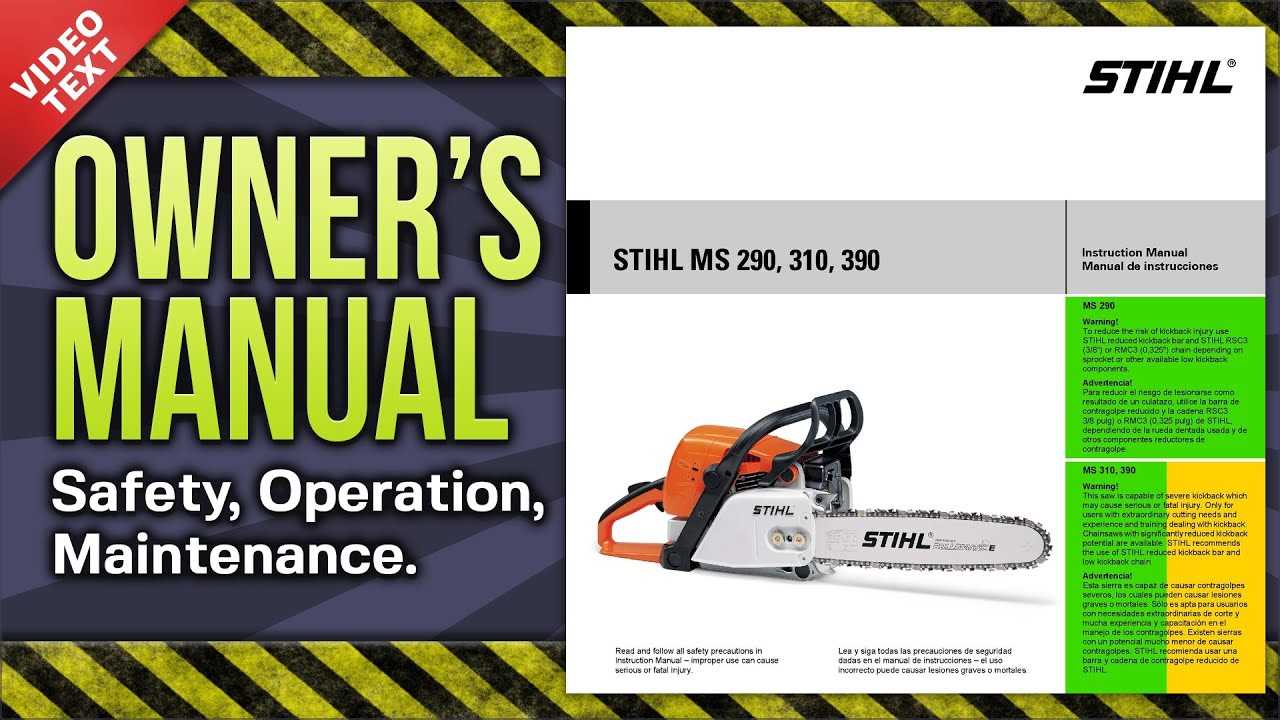

Understanding the essentials of a high-performance tool is crucial for achieving optimal results. This section aims to provide insights into the effective operation and upkeep of a powerful cutting device, ensuring longevity and efficiency in its use.

Following comprehensive instructions not only enhances performance but also contributes to safety during operation. By adhering to recommended practices, users can maximize the benefits of their equipment while minimizing the risk of malfunctions.

Regular maintenance is a key component in preserving the functionality of any machinery. This ensures that all components remain in top condition, thus enhancing the overall user experience.

Moreover, staying informed about common issues and solutions will empower users to tackle challenges effectively. This knowledge fosters a deeper connection with the tool and encourages a more confident approach to its utilization.

Understanding Your Chainsaw

This section aims to provide insights into operating and maintaining a specific type of cutting tool. By familiarizing yourself with its features and functions, you can enhance your efficiency and safety during usage.

| Feature | Description |

|---|---|

| Engine Type | Powerful motor designed for heavy-duty tasks. |

| Chain Length | Optimal size for various cutting applications. |

| Weight | Lightweight design for easy handling. |

| Safety Features | Includes chain brake and throttle lock for protection. |

Essential Maintenance Tips for Longevity

Regular upkeep is crucial for ensuring the durability and efficient performance of your equipment. By adhering to a systematic maintenance routine, you can enhance functionality, reduce the risk of breakdowns, and extend the lifespan of your machinery.

Routine Inspections

Performing consistent checks is vital. Examine components for wear and tear, and ensure that all parts are securely fastened. Addressing minor issues before they escalate can save time and resources in the long run.

Proper Cleaning

Keeping your device clean not only improves its appearance but also prevents the accumulation of debris that can hinder performance. Regularly clear away any residue from the air filter, bar, and chain to maintain optimal operation. Additionally, lubricate moving parts as recommended to minimize friction and wear.

Safety Precautions When Operating Chainsaws

Operating a chainsaw requires utmost attention and adherence to safety protocols to prevent accidents and injuries. Proper understanding of the equipment and the environment is essential for safe operation.

Personal Protective Equipment (PPE) is crucial when using cutting tools. Always wear a hard hat, eye protection, hearing protection, and sturdy footwear to safeguard against potential hazards.

Before starting, ensure the chainsaw is in good condition. Inspect the chain for damage, check the fuel and oil levels, and verify that all components are secure. This maintenance helps reduce the risk of malfunctions during use.

When operating, maintain a firm grip and a stable stance. Keep both hands on the handles at all times to enhance control. Additionally, be aware of your surroundings, looking out for obstacles and bystanders.

Always follow the manufacturer’s guidelines for starting and using the equipment. This includes understanding the correct operating techniques and recognizing the signs of fatigue or strain.

In case of emergency, be prepared to respond swiftly. Know how to shut off the chainsaw quickly and keep a first-aid kit nearby. Awareness and preparedness can significantly minimize the risks associated with chainsaw operation.