When it comes to handling cutting tools, understanding their functionalities and ensuring proper care is essential for optimal performance and safety. This section aims to provide valuable insights into the effective use of a specific model, covering everything from basic operational procedures to advanced maintenance tips.

Proper guidance can greatly enhance the experience of users, enabling them to navigate potential challenges with confidence. By following comprehensive instructions, individuals can maximize the efficiency of their equipment, ensuring longevity and reliable operation.

In the following segments, readers will find crucial information that addresses common queries and offers step-by-step directions for routine upkeep. This resource is designed to empower users, fostering a deeper connection with their tools while promoting best practices in handling and maintenance.

This section highlights the key attributes and functionalities that make this chainsaw model a reliable choice for users. Understanding these essential aspects is crucial for maximizing performance and ensuring safe operation.

| Feature | Description |

|---|---|

| Powerful Engine | Equipped with a robust motor that delivers high torque for efficient cutting tasks. |

| Ergonomic Design | Designed for user comfort, reducing fatigue during extended usage. |

| Easy Start System | Features a simple starting mechanism that enhances user convenience. |

| Fuel Efficiency | Optimized for lower fuel consumption, promoting longer operational time. |

| Safety Features | Incorporates advanced safety mechanisms to minimize risks while in use. |

Maintenance Tips for Optimal Performance

Ensuring peak functionality of your equipment requires regular upkeep and attention. By implementing a consistent maintenance routine, you can significantly extend the lifespan of your tool while enhancing its efficiency during operation.

1. Regular Cleaning: After each use, it’s essential to clean the exterior thoroughly. Remove any debris, dirt, or sap to prevent buildup that can hinder performance.

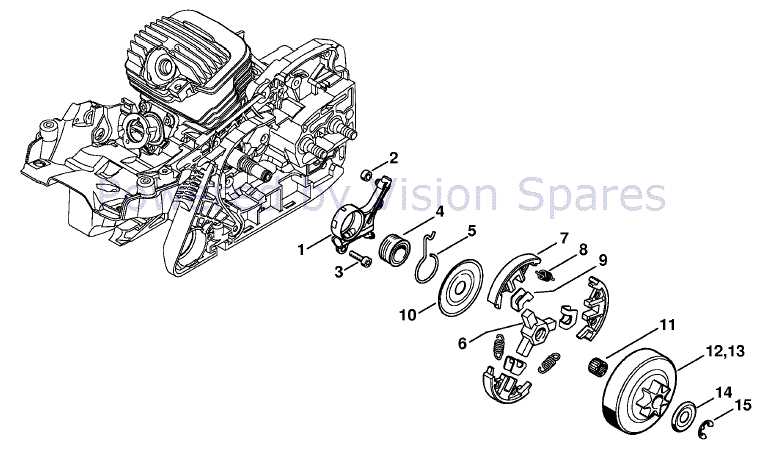

2. Chain Maintenance: Keep the cutting chain properly sharpened and lubricated. A well-maintained chain not only performs better but also reduces wear on the engine.

3. Air Filter Care: Inspect and clean the air filter periodically. A clean filter allows for optimal airflow, ensuring that the engine operates efficiently.

4. Fuel Quality: Use fresh, high-quality fuel to avoid potential engine issues. Stale or contaminated fuel can lead to poor performance and increased emissions.

5. Routine Inspections: Regularly check all components for signs of wear or damage. Addressing minor issues before they escalate can save time and repair costs in the long run.

Implementing these maintenance practices will ensure that your equipment remains in excellent working condition, providing reliable performance for years to come.

Safety Guidelines for Safe Operation

Ensuring safety while operating power tools is crucial to prevent accidents and injuries. Following established protocols and guidelines can significantly reduce risks and enhance the overall experience of using such equipment.

Before engaging in any operation, it is essential to be aware of the following safety measures:

- Always wear appropriate personal protective equipment, including gloves, goggles, and ear protection.

- Inspect the tool thoroughly before use to ensure it is in good working condition.

- Maintain a clear and organized workspace, free from hazards and distractions.

- Familiarize yourself with the tool’s features and controls before starting.

During operation, adhere to these critical practices:

- Maintain a firm grip on the tool with both hands for better control.

- Keep bystanders and pets at a safe distance to avoid accidents.

- Always cut at waist height and avoid overreaching.

- Be mindful of your surroundings and stay alert for potential hazards.

After completing your work, ensure to follow these post-operation guidelines:

- Turn off the equipment and allow it to cool down before handling.

- Store the tool in a secure location, away from unauthorized users.

- Regularly clean and maintain the tool to ensure its longevity and safe performance.

By adhering to these safety guidelines, operators can significantly reduce the risk of accidents and injuries, ensuring a safer working environment.