This section provides essential information regarding the operation and maintenance of automatic entry systems designed for residential use. Understanding the functionality and features of these devices is crucial for ensuring optimal performance and longevity. Users will find practical guidance on setup, troubleshooting, and routine upkeep.

Throughout this guide, various aspects of these systems will be explored, highlighting key components and their roles in enhancing convenience and security. By familiarizing yourself with the intricacies of the equipment, you can make informed decisions and enjoy the full benefits of your installation.

Whether you are a first-time user or looking to refresh your knowledge, this resource aims to empower you with the necessary skills to navigate common challenges effectively. Proper awareness and application of the tips provided will contribute to a seamless experience with your automatic entry solution.

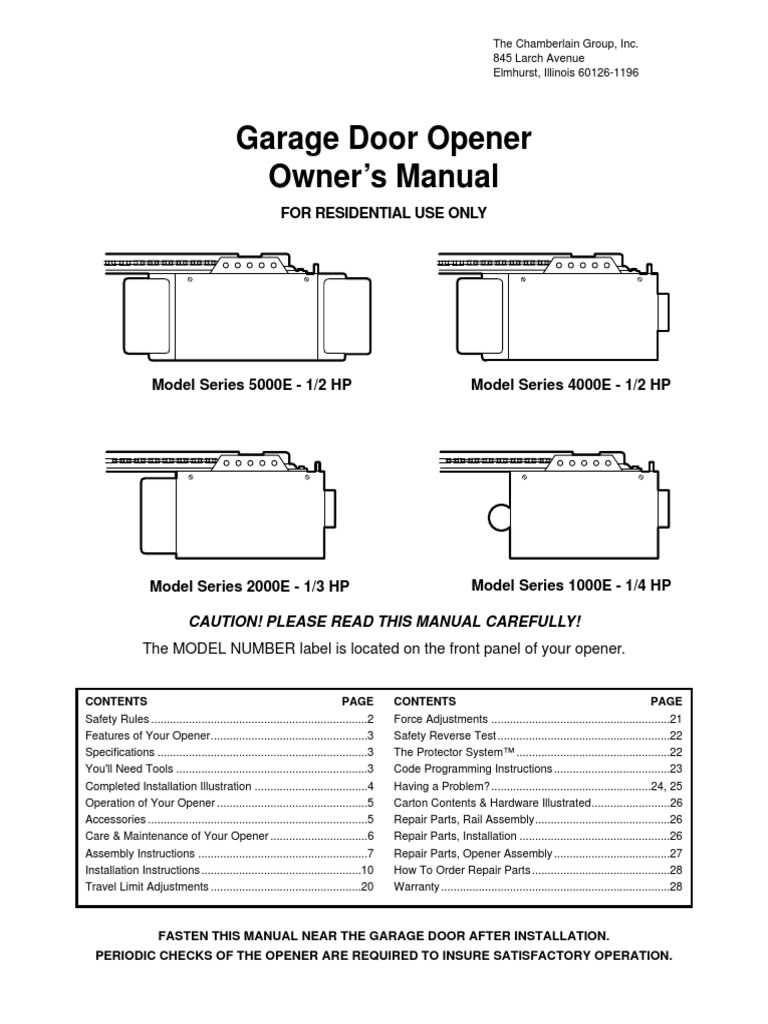

Understanding Your Garage Door Opener

Having a reliable mechanism for accessing your vehicle or storage area is essential for convenience and security. Familiarizing yourself with the functionalities and components of this device can enhance its usage and longevity. This section aims to provide insights into how these systems operate and the various features they offer.

Key Components and Their Functions

The primary parts of this mechanism include the motor, the track, and the remote control system. The motor provides the necessary power to move the entryway, while the track guides it smoothly along its path. The remote control allows for effortless operation, enabling you to open or close the system from a distance.

Maintenance and Safety Tips

Regular maintenance is crucial to ensure optimal performance. Checking the components for wear and tear, ensuring proper lubrication, and testing the safety features can prevent potential malfunctions. Always be aware of safety protocols, such as ensuring that the pathway is clear before activation and understanding emergency release mechanisms.

Common Issues and Troubleshooting Tips

This section addresses frequent challenges that users may encounter with their lifting mechanisms. Understanding these problems can significantly enhance functionality and extend the lifespan of the equipment. Below are some common issues along with effective solutions.

Frequent Problems

- Inconsistent operation

- No response to remote control commands

- Unusual noises during operation

- System not responding to wall switches

Troubleshooting Steps

- Check the power supply to ensure the unit is plugged in and functioning.

- Inspect the remote control batteries; replace them if necessary.

- Examine the sensors for obstructions and clean them if needed.

- Ensure that the tracks are clear of debris and aligned properly.

- Look for loose or damaged components and tighten or replace as needed.

By following these tips, users can often resolve issues independently, ensuring smooth operation and minimizing the need for professional assistance.

Maintenance Practices for Longevity

Ensuring the durability and efficient operation of mechanical devices requires regular care and attention. By implementing a few essential practices, users can significantly extend the lifespan of their equipment, minimizing the need for costly repairs and replacements.

Routine inspections play a crucial role in identifying potential issues before they escalate. Regularly checking for signs of wear, loose components, and unusual noises can help in maintaining optimal performance. Additionally, keeping the area around the mechanism clean and free of debris prevents obstruction and facilitates smooth operation.

| Practice | Frequency | Benefits |

|---|---|---|

| Lubrication of moving parts | Every 3-6 months | Reduces friction and prevents wear |

| Inspection of electrical connections | Every 6 months | Ensures safety and reliability |

| Adjustment of tension settings | Annually | Maintains proper operation and safety |

| Cleaning of sensors | Every 3 months | Enhances responsiveness and functionality |

By adhering to these maintenance practices, users can ensure that their equipment remains reliable and efficient over time, ultimately leading to enhanced performance and longevity.