This comprehensive guide aims to assist users in maximizing the potential of their innovative workbench tool, designed to enhance productivity and efficiency in various projects. With its sturdy construction and adaptable features, this equipment serves as an indispensable companion for both professionals and DIY enthusiasts alike.

Throughout this document, you will find detailed instructions and tips that will enable you to effectively utilize this multifunctional workstation. Whether you are engaged in woodworking, metalworking, or general home improvement tasks, understanding the capabilities and functionalities of this tool will empower you to achieve optimal results.

As you explore the contents of this guide, you will discover essential maintenance practices, safety precautions, and setup procedures. By following these guidelines, you can ensure a seamless experience while harnessing the full potential of your versatile workstation, making every project a success.

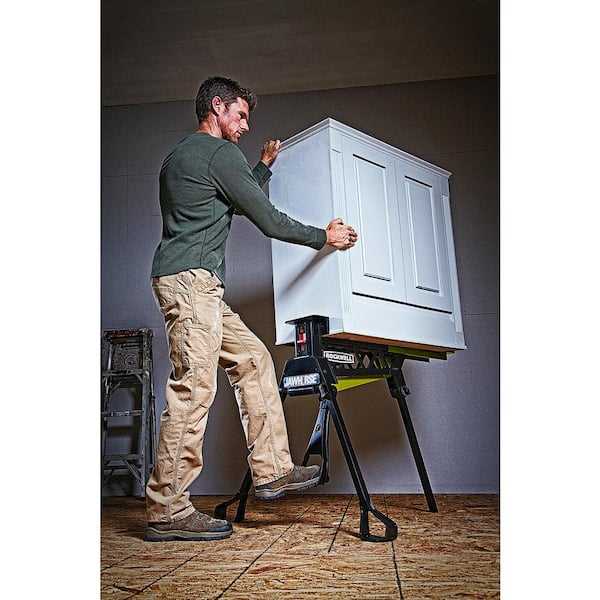

Understanding the Rockwell Jawhorse Features

This section delves into the distinctive characteristics of a versatile workholding solution designed for various tasks. It offers an array of functionalities that enhance productivity and efficiency, making it an invaluable addition to any workshop or job site.

Key Functionalities

One of the standout features is its remarkable clamping ability, allowing users to securely hold materials of various shapes and sizes. This adaptability makes it ideal for woodworking, metalworking, and numerous DIY projects. Additionally, its compact design ensures easy transport and storage, enabling users to work effectively in tight spaces.

Enhanced Stability and Support

Equipped with a robust frame, this equipment provides exceptional stability during use. Its adjustable components ensure that different workpieces are supported adequately, minimizing the risk of accidents. The combination of strength and flexibility positions this tool as a go-to solution for both professional tradespeople and hobbyists.

Setting Up Your Jawhorse for Use

Properly preparing your versatile work support is crucial for achieving optimal performance and safety during tasks. This process involves a few essential steps to ensure that the equipment is stable, secure, and ready to accommodate various materials and projects. Follow these guidelines to set up effectively and enhance your productivity.

Choosing the Right Location

Start by selecting a flat and sturdy surface to position your equipment. Avoid areas with loose gravel or uneven ground that may compromise stability. Ensure there is ample space around the device for easy access and movement. This will provide a safe working environment and reduce the risk of accidents.

Adjusting the Support Features

Once in place, adjust the height and clamping mechanisms according to your project requirements. Ensure that the support arms are securely locked in position before use. This step is vital for maintaining stability during operation and will help in effectively securing various workpieces. After adjustments, perform a quick check to verify that everything is tightly secured before commencing any task.

Safety Tips for Jawhorse Operation

Ensuring a safe working environment is crucial when operating any tool designed for clamping and holding materials. Following specific guidelines can significantly reduce the risk of accidents and injuries. Proper awareness and preparation will help you maximize efficiency while safeguarding your well-being.

1. Read the Instructions: Familiarize yourself with the manufacturer’s guidelines before using the equipment. Understanding the tool’s features and limitations is essential for safe operation.

2. Wear Personal Protective Equipment: Always don appropriate safety gear, including gloves, goggles, and sturdy footwear. This gear protects against potential hazards that may arise during use.

3. Maintain a Clean Workspace: Keep the area free from clutter and obstacles. A tidy environment allows for better visibility and reduces the chances of tripping or slipping.

4. Check for Damage: Inspect the equipment regularly for any signs of wear or damage. If you notice any issues, refrain from using it until repairs are made to ensure safe functionality.

5. Secure Materials Properly: Always ensure that the items being clamped are securely positioned. Improperly secured materials can shift unexpectedly, leading to potential injuries.

6. Avoid Distractions: Stay focused during operation. Distractions can lead to mistakes that may result in accidents. Concentration is key to safe usage.

7. Follow Load Limits: Adhere strictly to the recommended load capacity. Overloading the equipment can compromise its stability and increase the risk of failure.

8. Disconnect When Not in Use: When finished, ensure that the tool is properly stored and disconnected from power sources to prevent unauthorized or accidental activation.