Preparing your outdoor tools for the colder months can make a significant difference in maintaining their efficiency and longevity. Ensuring that your device is well-maintained and ready for use is key to avoiding malfunctions during challenging weather conditions. This section covers the essentials of keeping your machinery in top shape through proper care and periodic check-ups.

In this guide, we’ll walk through vital procedures for maintaining your equipment, including tips for regular upkeep and troubleshooting. Whether you’re storing it for the off-season or getting it ready for another winter, our recommendations will help extend the life of your machine while keeping it running smoothly when you need it most.

By following these guidelines, you can avoid common problems and ensure that your winter gear is always prepared to handle the toughest conditions. Maintenance doesn’t have to be complicated, and with the right approach, you’ll ensure that your tools perform efficiently year after year.

Essential Features of Your Snow Removal Machine

Understanding the key components of your winter clearing equipment is crucial for efficient and reliable operation. Each part plays a vital role in ensuring the machine functions optimally, especially in challenging weather conditions. Familiarizing yourself with these features will help you maintain and use the equipment safely and effectively.

Powerful Engine

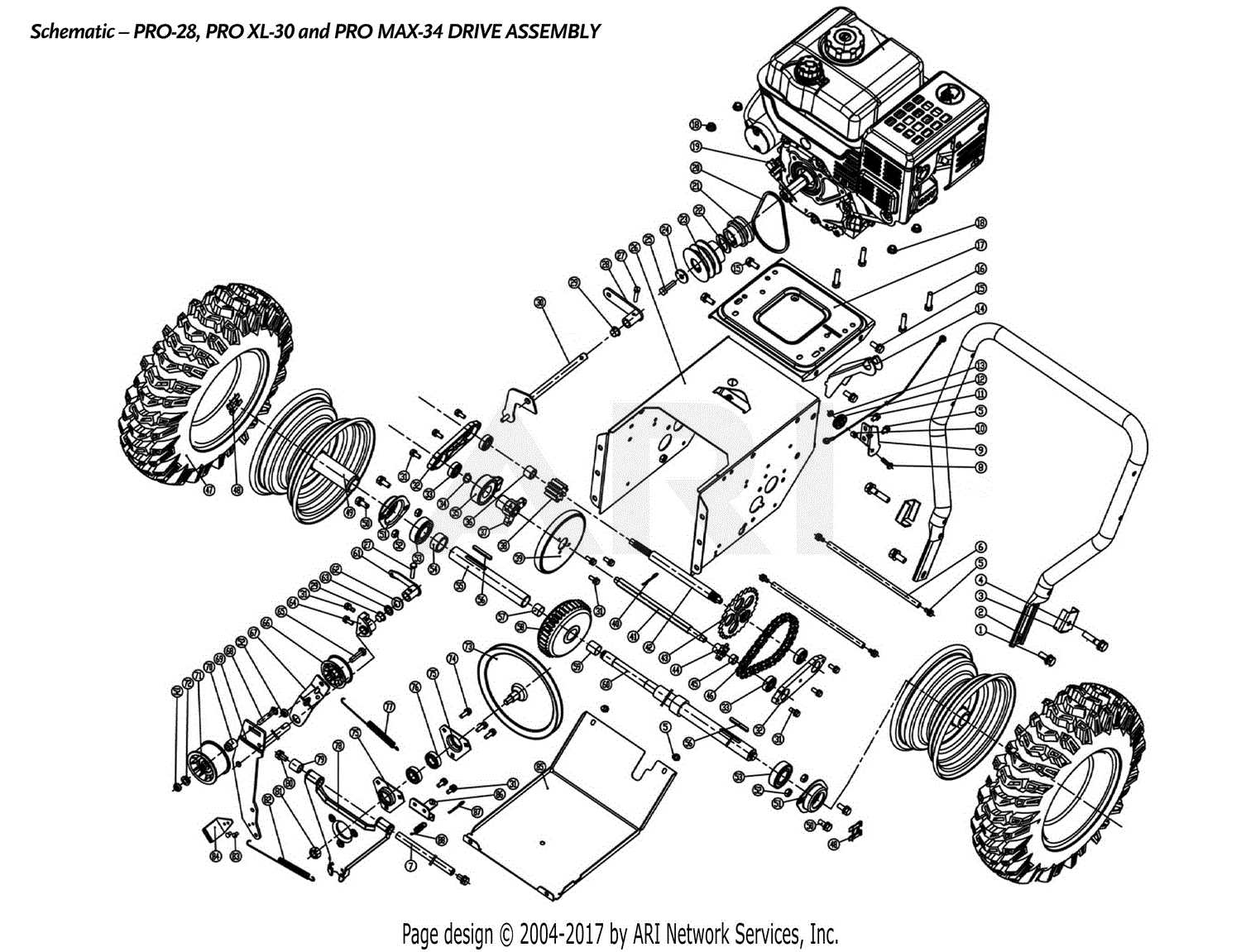

The heart of your machine is its motor, which provides the strength needed to handle heavy-duty tasks. A robust engine ensures that the equipment can handle dense or compacted layers with ease, allowing for quicker and more efficient clearing of outdoor spaces.

Adjustable Clearing Width

One of the most useful features of this type of equipment is the adjustable working width. This allows you to tailor the device’s performance to the size of the area you are working in, improving precision and speed. Whether you’re dealing with narrow pathways or larger driveways, the flexibility in width ensures optimal results.

Durable materials and effective controls further enhance the performance, allowing you to operate the machine with minimal effort even in tough conditions

Proper Maintenance and Care Tips

Regular upkeep is essential for ensuring the longevity and efficiency of your equipment. By following a consistent care routine, you can prevent common issues and keep the machine performing optimally throughout its lifespan.

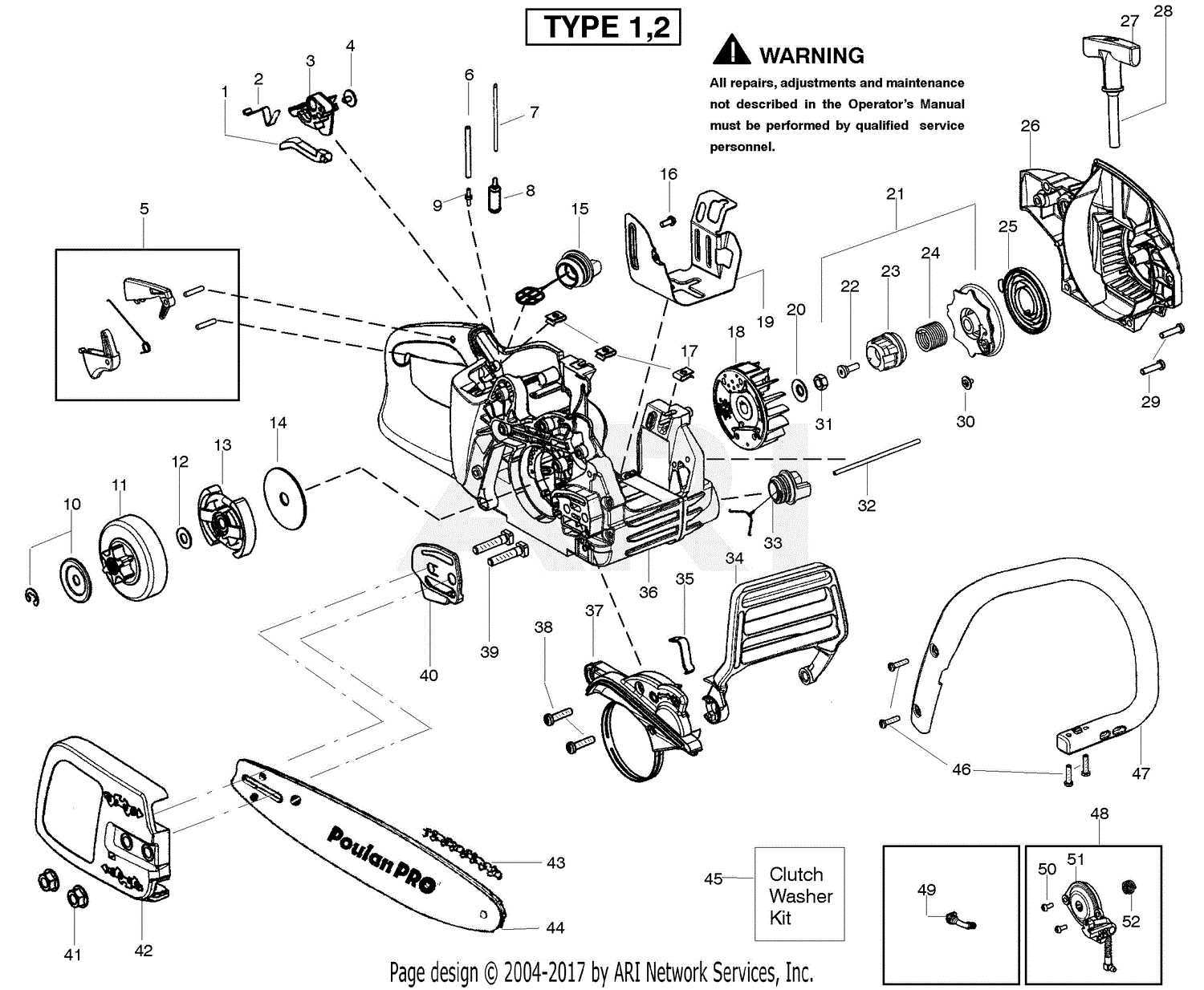

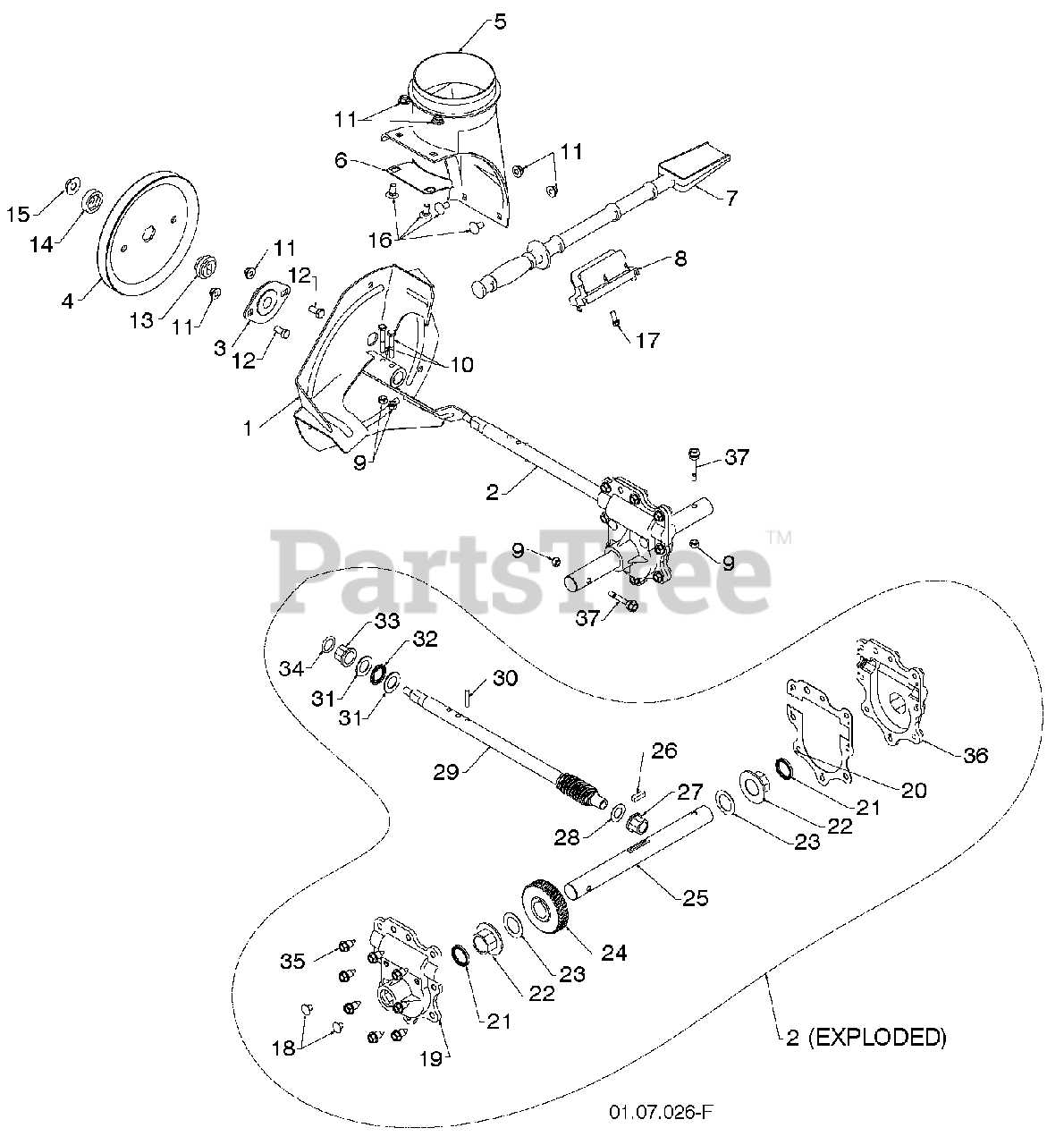

Check and Replace Worn Parts

It’s crucial to periodically inspect all moving components. If you notice any wear or damage, replacing parts like belts or blades in a timely manner can prevent larger issues. Keep an eye on these areas to avoid unexpected breakdowns.

Lubrication and Cleaning

Proper lubrication of all essential parts reduces friction and wear. Ensure that you are using the recommended type of oil or grease for the various mechanisms. Additionally, regularly clean off any debris or buildup to prevent blockages or strain on the motor.

Following these basic maintenance tips will significantly extend the lifespan of your equipment, ensuring smooth operation for years to come.

Common Troubleshooting for Winter Conditions

During the colder months, machines used for clearing paths and driveways may encounter various operational issues due to harsh weather conditions. Understanding these potential challenges and their solutions can help ensure smooth and efficient operation. Below are common issues that can arise in freezing temperatures, along with tips to resolve them.

Engine Won’t Start

One of the most frequent problems is difficulty starting the engine in cold weather. This could be caused by stale fuel, improper oil viscosity, or a clogged carburetor. Ensure that fresh fuel is used, and the machine has been properly maintained for winter use.

- Check the fuel tank and refill with fresh, winter-grade fuel.

- Make sure the oil is suited for low temperatures.

- Inspect the carburetor for blockages and clean if necessary.

Reduced Performance or Stalling

Another common issue is reduced efficiency or frequent stalling when operating in heavy conditions. This can often be linked to a clogged intake, icy buildup, or mechanical wear.

- Clear any debris or ice from the intake and chute areas.

- Inspect belts and augers for signs of wear or damage.

- Allow the machine to warm up before