The effective use and upkeep of machinery are crucial for ensuring long-term performance and minimizing downtime. Whether working on a construction site or managing a large agricultural operation, having a thorough understanding of machine functions is essential for maximizing productivity and safety.

Every piece of equipment has its unique characteristics that require attention. Proper handling, regular servicing, and adherence to operational guidelines play a pivotal role in maintaining efficiency and prolonging the lifespan of machinery. This guide provides step-by-step insights into essential practices, helping operators gain confidence in managing their machines effectively.

Additionally, understanding the detailed specifications and features of your equipment is key to optimizing its use in different scenarios. By following best practices and maintenance routines, users can enhance performance while preventing potential issues that may arise during daily tasks. This document aims to offer practical advice and recommendations for achieving these goals.

Essential Maintenance Tips for New Holland LS170

Regular upkeep is crucial to ensure the longevity and optimal performance of any equipment. Proper care not only prevents unexpected breakdowns but also maximizes efficiency during operation. This section outlines some key practices that will help maintain your machinery in top condition, ensuring a smooth workflow.

Keep Fluids at Optimal Levels

Monitoring and maintaining the right levels of fluids such as hydraulic oil, coolant, and engine lubricant is essential. Low levels can cause overheating, reduced performance, and increased wear on internal components. Always check these levels before starting work, and use quality products to guarantee better performance.

Inspect Filters and Replace When Necessary

Filters play a significant role in protecting the engine and hydraulic system from dirt and contaminants. Over time, these elements can clog, reducing efficiency and causing potential damage. Make it a habit to inspect filters regularly and replace them as recommended. Using the right replacement parts will help maintain optimal functioning.

Note: Implementing these practices not only extends the lifespan of your equipment but also ensures a safer operating environment. Regular attention to these small details can prevent costly repairs and downtime.

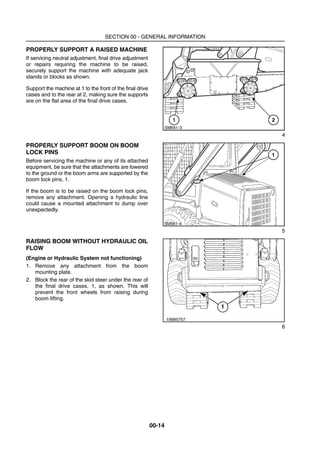

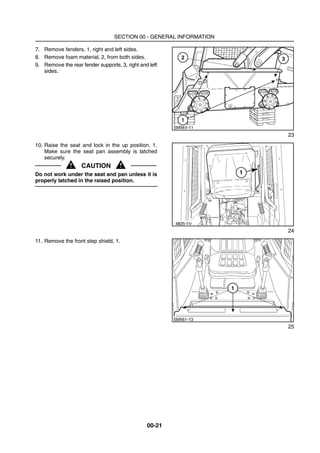

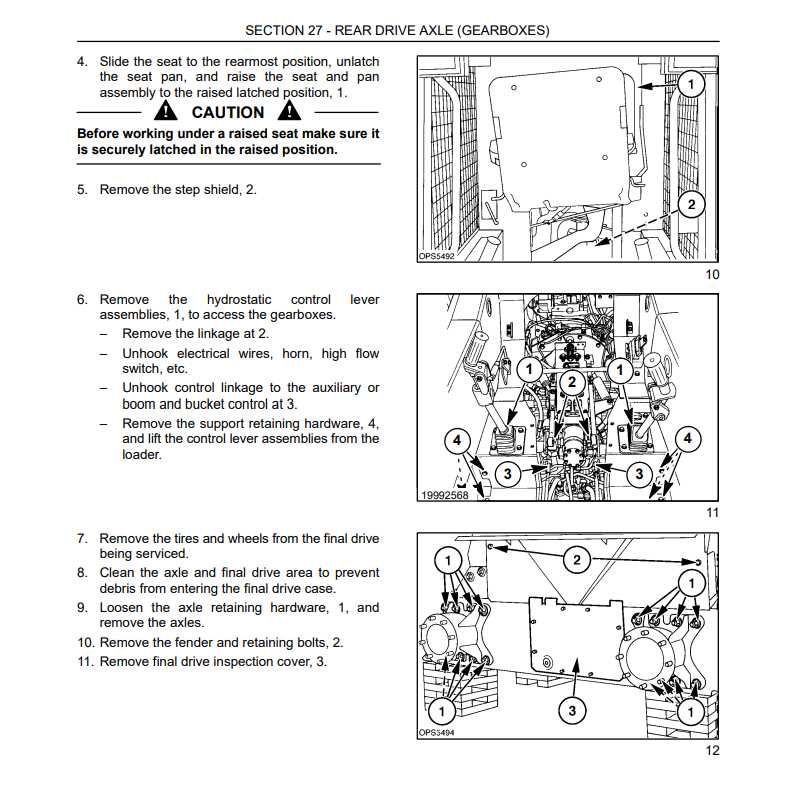

Understanding Safety Precautions and Guidelines

Proper adherence to safety measures is essential for preventing hazards and ensuring smooth operation. This section provides critical insights to help users recognize potential risks and implement the right strategies for maintaining a secure environment. Knowing and applying these guidelines is crucial for avoiding mishaps during equipment use.

General Safety Recommendations

Operators must familiarize themselves with key protocols before handling any machinery. These recommendations focus on creating safe working conditions, minimizing risks, and promoting responsible usage. Adequate training and awareness are fundamental for achieving these goals.

| Precaution | Description |

|---|---|

| Protective Gear | Always wear appropriate protective equipment, including gloves, safety glasses, and sturdy footwear to reduce injury risks. |

| Regular Inspections | Conduct routine checks to identify and address any signs of wear or damage that could affect performance or safety. |

| Clear Work Area | Ensure the operating area is free of obstacles, and maintain proper visibility to avoid unintended contact or accidents. |

Emergency Response Tips

Being prepared for unexpected situations is a vital component of safety management. Knowing how to respond swiftly and effectively can significantly mitigate potential dangers and reduce damage.