Owning an agricultural vehicle can significantly enhance productivity on the farm. Understanding how to effectively operate and maintain your machinery is crucial for ensuring its longevity and efficiency. This section will provide essential information that every operator should be familiar with to maximize the performance of their equipment.

From basic operational procedures to routine maintenance tips, this guide aims to equip you with the knowledge needed for successful usage. It covers key aspects such as safety measures, troubleshooting common issues, and best practices for upkeep, ensuring your machine runs smoothly throughout its operational lifespan.

By familiarizing yourself with these guidelines, you will not only optimize the functionality of your agricultural asset but also safeguard your investment. This comprehensive overview will serve as a valuable resource as you navigate the responsibilities of machinery management.

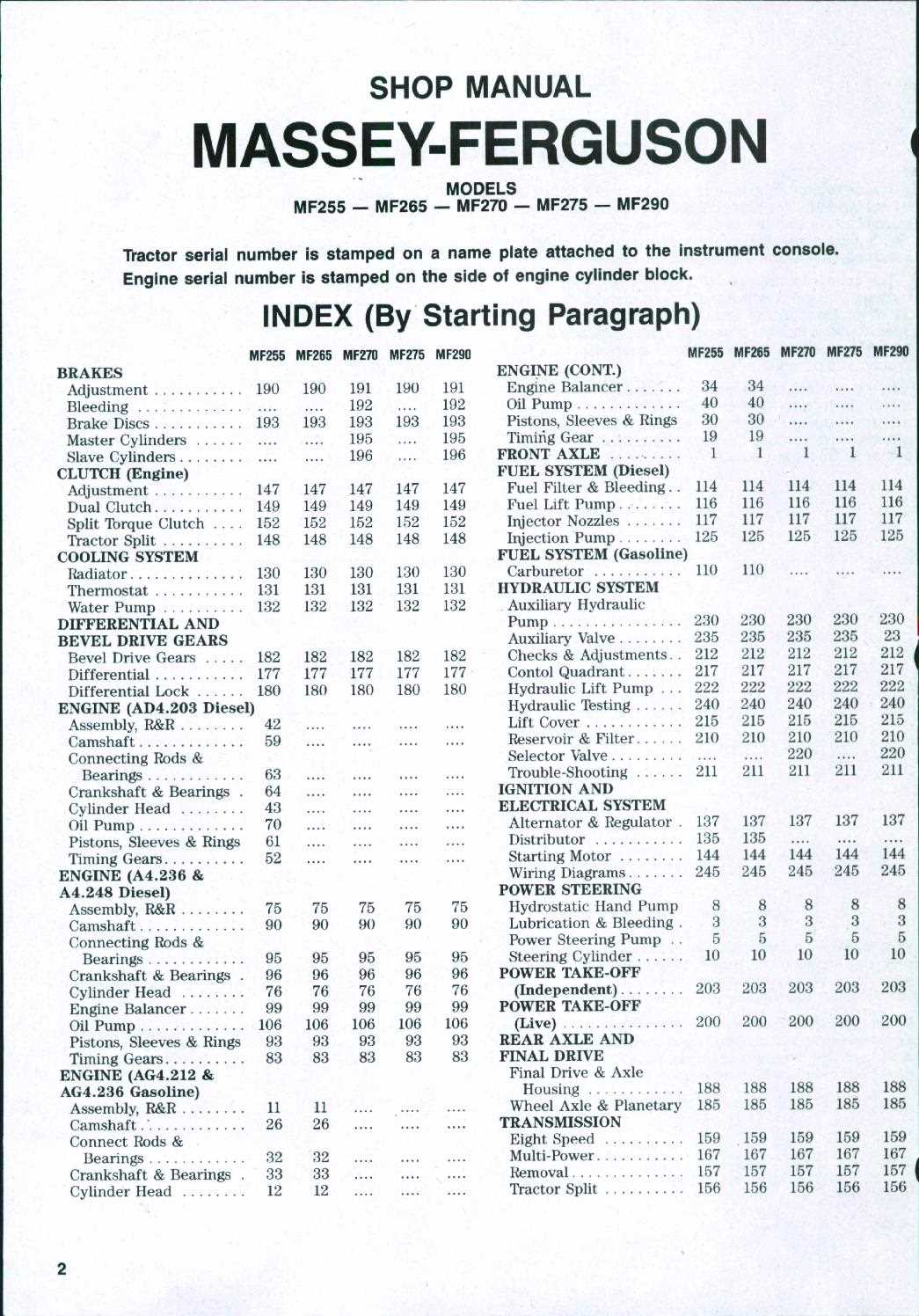

General Overview of the Tractor Model

This section provides an in-depth look at a popular agricultural machine known for its reliability and efficiency. The vehicle is designed to assist farmers in various tasks, from plowing fields to transporting goods. Its robust build and advanced features make it a valuable asset in modern farming operations.

The following highlights showcase the key aspects of this tractor:

- Performance: Engine power and torque ratings enable effective operation in diverse agricultural environments.

- Durability: Constructed with high-quality materials to withstand harsh conditions.

- Versatility: Compatible with a range of implements, enhancing productivity in various tasks.

- User-friendly Controls: Designed with an intuitive interface for ease of operation.

- Maintenance: Simple upkeep procedures to ensure long-lasting performance.

Understanding the functionalities and features of this machine is essential for maximizing its potential in everyday tasks.

Maintenance Tips for Optimal Performance

Regular upkeep is essential for ensuring that your agricultural equipment operates at its best. By implementing systematic care and attention, you can enhance efficiency, prolong lifespan, and minimize the risk of unexpected breakdowns. The following guidelines will help you maintain peak functionality.

1. Routine Inspections: Conduct frequent checks of all critical components. Look for signs of wear and tear, including hoses, belts, and filters. Addressing minor issues promptly can prevent more significant problems later.

2. Fluid Levels: Regularly monitor and maintain appropriate fluid levels, including engine oil, hydraulic fluid, and coolant. Clean fluids are vital for smooth operation and preventing overheating.

3. Cleaning: Keep your machinery clean by removing dirt, debris, and residue after each use. This practice not only improves performance but also helps in identifying potential issues before they escalate.

4. Scheduled Servicing: Adhere to a servicing schedule as recommended by the manufacturer. Professional maintenance checks can uncover hidden problems and ensure that all systems function correctly.

5. Tire Maintenance: Check tire pressure regularly and ensure proper alignment. Well-maintained tires enhance traction and improve fuel efficiency.

By following these maintenance tips, you can ensure that your equipment runs smoothly, effectively, and reliably, helping you achieve your agricultural goals.

Common Issues and Troubleshooting

Understanding potential challenges that may arise during operation is essential for effective maintenance and ensuring optimal performance of agricultural machinery. Identifying and addressing common problems promptly can help minimize downtime and enhance productivity.

Here are some frequent issues encountered and their corresponding troubleshooting tips:

- Engine Won’t Start:

- Check the fuel level and ensure it is adequate.

- Inspect the battery for charge and connections.

- Look for any blown fuses or faulty ignition components.

- Overheating:

- Examine the coolant level and top it up if necessary.

- Ensure the radiator is clean and free of debris.

- Inspect the thermostat for proper functioning.

- Poor Performance:

- Check the air filter for dirt and clogs, and replace if needed.

- Ensure fuel quality is satisfactory.

- Inspect the exhaust system for blockages.

- Hydraulic Issues:

- Check the hydraulic fluid level and refill if low.

- Inspect hoses and connections for leaks.

- Ensure that the hydraulic filter is clean and functioning.

Regular maintenance and prompt attention to these common issues can significantly improve the longevity and efficiency of your machinery.