The trusted utility vehicle described in this guide has long been a cornerstone of agricultural work, renowned for its reliable performance and adaptability across a wide range of farming tasks. This robust machinery has been serving farmers for decades, offering a perfect balance of power, efficiency, and ease of use. Whether tending to fields, transporting heavy loads, or managing everyday farm chores, this machine remains an invaluable partner on the farm.

This comprehensive guide provides all the necessary insights to maintain and operate this agricultural marvel effectively. It covers essential information on maintenance schedules, troubleshooting tips, and operational guidelines to ensure your equipment runs smoothly season after season. Designed with the user in mind, the handbook is an indispensable resource for both new and experienced operators looking to maximize the lifespan and performance of their machinery.

Emphasizing safety and optimal use, this guide also highlights best practices for keeping your equipment in peak condition. From routine checks to more complex adjustments, every aspect of care is detailed with clear instructions and helpful advice. This section is dedicated to empowering users with the knowledge to confidently handle their equipment, ensuring it continues to be a reliable asset on the farm for years to come.

Massey Ferguson 245 Maintenance Guide

Proper upkeep of your agricultural equipment is essential to ensure longevity, efficiency, and optimal performance in the field. This section provides an insightful guide on essential maintenance routines that keep your machine in top shape, helping you avoid costly repairs and downtime.

Routine Checks and Fluid Maintenance

Regular inspection and fluid maintenance play a critical role in extending the life of your machinery. Key aspects include monitoring oil levels, checking hydraulic fluids, and ensuring coolant levels are adequate to prevent overheating during operation.

- Inspect engine oil levels frequently and replace the oil at recommended intervals.

- Check hydraulic fluid levels and inspect for leaks; ensure that the system is free from air.

- Examine the coolant reservoir, maintaining proper levels to avoid engine damage.

- Replace filters regularly, including air, fuel, and oil filters, to ensure optimal engine performance.

Mechanical Parts and Components

Keeping mechanical components in good condition is crucial for the smooth operation of your machine. Pay attention to moving parts, belts, and connections to prevent unexpected failures.

- Inspect belts for wear and tension; replace any that show signs of cracking or fraying.

- Grease moving joints and linkages according to the maintenance schedule to reduce friction and wear.

- Examine the tire pressure and tread condition regularly, adjusting as necessary for stable performance.

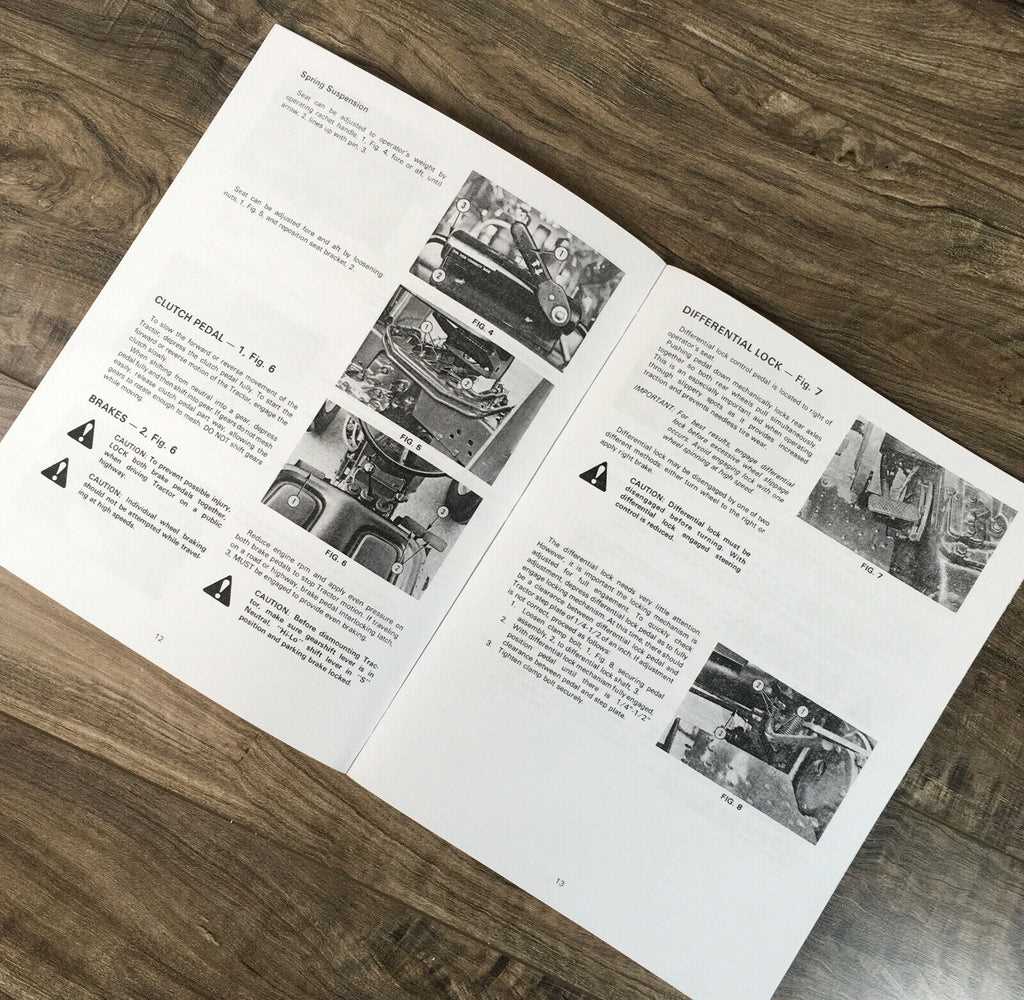

- Check the brake system and clutch operation, ensuring all controls respond correctly to inputs.

By adhering to these maintenance guidelines, you can ensure your agricultural machine remains reliable and efficient, ready to handle the demands of any task on the farm.

Essential Maintenance Tips for Longevity

Regular upkeep is vital to ensure the long-lasting performance of your equipment. By adhering to a consistent maintenance schedule, you can avoid unexpected breakdowns, improve efficiency, and extend the operational life of your machine. Paying attention to key areas and using proper techniques will help keep your equipment running smoothly.

1. Routine Inspection and Cleaning

Regularly inspect your machine for any signs of wear, leaks, or loose parts. Clean all essential components, including the engine, filters, and cooling system, to prevent dust and debris from accumulating. Ensuring that all parts are free from dirt and obstructions will reduce the strain on your equipment and enhance its overall performance.

2. Lubrication and Fluid Checks

Proper lubrication is crucial for the smooth operation of moving parts. Check and replace engine oil, hydraulic fluids, and other essential lubricants as recommended. Monitor fluid levels frequently to prevent overheating and ensure that seals and gaskets are in good condition to avoid leaks. Keeping your fluids at optimal levels will reduce friction and prevent premature wear.

Common Issues and How to Resolve Them

This section covers frequent problems encountered during operation and maintenance, along with practical solutions to ensure smooth functionality and longevity. Addressing these challenges early on can help maintain optimal performance and prevent more serious complications.

Engine Troubles

- Starting Issues: If the engine struggles to start, check the battery connections and ensure there is sufficient charge. Inspect the fuel lines for blockages or air leaks that could disrupt the fuel flow.

- Overheating: Overheating can often be caused by a clogged radiator, low coolant levels, or a faulty thermostat. Regularly clean the radiator and monitor coolant levels to prevent engine damage.

- Unusual Noises: Strange noises such as knocking or rattling may indicate loose components, worn bearings, or insufficient lubrication. Regular inspections and timely replacements of worn parts are essential.

Hydraulic System Failures

- Slow or Non-Responsive Lifting: If lifting mechanisms are sluggish or unresponsive, check the hydraulic fluid levels. Low fluid or contaminated oil can impair performance. Refill or replace the fluid as needed.

- Leaks in Hydraulic Lines: Leaks can lead to loss of pressure and inefficiency. Inspect hoses and seals for cracks or wear, and replace any damaged components to maintain system integrity.

Regular maintenance and timely attention to these common issues will greatly enhance operational efficiency and prolong the life of your equipment. Keeping a proactive approach towards inspections and repairs is key to avoiding major breakdowns.

Recommended Service Intervals and Checks

Regular maintenance is crucial for ensuring the long-term reliability and performance of your equipment. Adhering to recommended service intervals helps identify potential issues early, minimizing downtime and preventing costly repairs. This section outlines key checks and maintenance tasks that should be performed routinely to keep your machine running smoothly.

Daily Checks: Before starting each day, inspect fluid levels, including engine oil, coolant, and hydraulic fluid. Examine tires for proper inflation and damage. Check all lights and signals to ensure they are functioning correctly. A visual inspection of belts and hoses can also help spot wear or cracks.

Weekly Maintenance: Clean or replace air filters to maintain optimal airflow. Lubricate moving parts to prevent wear and ensure smooth operation. Inspect brakes and steering components for proper functionality. Check the battery terminals for corrosion and secure connections.

Monthly Inspections: Perform a thorough inspection of the drive system, including checking for any unusual noises or vibrations. Examine hydraulic systems for leaks and proper pressure levels. Inspect the exhaust system for signs of damage or blockage. Check all safety features, ensuring they are operational and meet safety standards.

Seasonal Service: At the start of each season, replace engine oil and filters to ensure efficient engine performance. Inspect fuel lines and replace them if any signs of wear are detected. Drain and replace coolant if it appears contaminated. Grease all joints and moving parts to protect against friction damage. Review and tighten all bolts and connections to prevent mechanical failures.

Regularly adhering to these service intervals and checks will help maintain the efficiency and reliability of your equipment, ensuring it remains in peak condition throughout its operational life.

Operating Instructions for Massey Ferguson 245

This section provides guidance on how to effectively operate your agricultural equipment. Understanding the correct procedures for starting, using, and maintaining the machinery will ensure safe and efficient performance in various working conditions. Follow the outlined steps to maximize the reliability and productivity of your equipment during field operations.

| Step | Instructions |

|---|---|

| 1. Pre-Start Checks | Inspect all fluid levels, including engine oil, coolant, and hydraulic fluids. Ensure that tires are properly inflated and that all safety guards and shields are securely in place. |

| 2. Starting the Engine | Ensure the gear lever is in neutral and the parking brake is engaged. Turn the ignition key to the start position, allowing the engine to warm up to optimal operating temperature before engaging any gears. |

| 3. Operating the Controls | Familiarize yourself with the throttle, steering, and implement control levers. Adjust the throttle for the required speed and carefully operate steering to maintain control over the equipment during tasks. |

| 4. Gear Selection | Select the appropriate gear based on the task and ground conditions. Use low gears for heavy-duty work such as plowing and higher gears for lighter tasks or transport. |

| 5. Using Attachments | Securely attach any implements using the hitch points and adjust the linkage according to the task requirements. Ensure that all connections are tight before operation. |

| 6. Stopping and Parking | To stop, reduce the throttle gradually, depress the clutch, and shift the gear lever to neutral. Engage the parking brake before shutting down the engine to ensure the equipment remains stationary. |

| 7. Post-Operation Inspection | After use, perform a visual inspection of the machinery, checking for any signs of wear or damage. Clean the exterior and remove any debris to mainta |