Taking care of your machinery is essential for ensuring long-lasting performance and avoiding unexpected breakdowns. Whether you’re dealing with a compact vehicle or a heavy-duty machine, understanding the key maintenance steps is crucial. This guide will offer you detailed insights to help you maintain and operate your equipment efficiently.

Regular upkeep can make a significant difference in how your machinery functions. With the right approach to maintenance, you can enhance performance, extend the lifespan of your equipment, and reduce the risk of costly repairs.

In the following sections, you will find practical advice and recommendations designed to simplify the maintenance process. Following these steps will help ensure your machinery operates smoothly and remains reliable under various working conditions.

Key Maintenance Tips for This Model

Proper care of your equipment is essential for ensuring its longevity and efficiency. Regular upkeep not only helps avoid unexpected breakdowns but also optimizes overall performance. It is important to follow the recommended guidelines to maintain all parts in good condition and prevent wear and tear from impacting functionality.

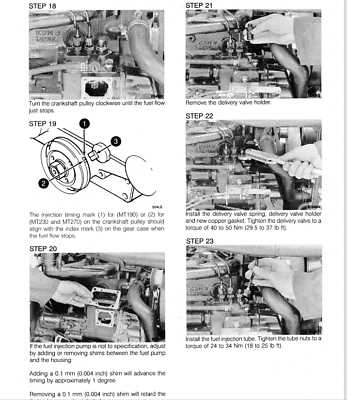

Engine Checks: Regularly inspect the engine to ensure all components are functioning properly. This includes checking oil levels, ensuring the air filters are clean, and keeping an eye on any unusual noises or vibrations that may indicate a potential issue.

Tire Maintenance: Proper tire inflation and alignment are crucial for smooth operation. Routinely check for any signs of wear or punctures, and make sure the tires are inflated according to the manufacturer’s specifications.

By adhering to these basic practices, you can significantly extend the life of your equipment and maintain its efficiency over time.

Common Issues and Their Solutions

When operating machinery, it is not uncommon to encounter a range of issues that may affect its performance. Understanding the most frequent problems can help you address them swiftly, ensuring your equipment remains in optimal condition and minimizing downtime.

Starting Problems

A common challenge with many machines is difficulty starting. This can be caused by a variety of factors, including battery issues, fuel supply interruptions, or clogged filters.

- Check the battery connections to ensure they are secure and free from corrosion.

- Inspect the fuel lines for any leaks or blockages.

- Replace the air and fuel filters regularly to prevent clogging.

Overheating

Another frequent issue is overheating, especially during prolonged use. This can be caused by poor cooling system maintenance or low fluid levels.

- Ensure the radiator is clean and free from debris.

Enhancing Performance with Regular Checks

Maintaining peak efficiency of your machinery requires consistent attention to its condition. By performing routine inspections, you ensure that all components are functioning as they should, reducing the risk of breakdowns and prolonging the equipment’s lifespan. Regular evaluations help identify potential issues early on, allowing for timely intervention and preventing costly repairs in the future.

Key areas to focus on include fluid levels, tire pressure, and ensuring all moving parts are well-lubricated. These simple checks can have a significant impact on the overall performance, allowing your equipment to operate smoothly and efficiently under various conditions.