This section provides essential information for users seeking to maximize their experience with their lawn maintenance equipment. Understanding the operational features, maintenance routines, and safety precautions is crucial for achieving optimal performance and longevity.

Effective utilization of this machinery involves familiarizing oneself with its various components and functionalities. Comprehensive knowledge empowers users to handle tasks efficiently while ensuring safety during operation. This guide emphasizes best practices that enhance the overall effectiveness of the equipment.

By following recommended procedures, individuals can ensure smooth operation and minimize potential issues. Regular maintenance not only prolongs the lifespan of the equipment but also guarantees that it operates at peak efficiency, meeting the user’s needs effectively.

This section aims to provide a comprehensive overview of the key characteristics and functionalities of the model in question. Understanding these features will enable users to optimize their experience and maintenance of the equipment.

Key Characteristics

Familiarizing yourself with the essential features of the machine can enhance its utility. Consider the following attributes:

- Robust engine performance

- Efficient cutting technology

- Advanced steering mechanisms

- Versatile attachment options

Functionality Insights

Knowledge of the operational aspects can significantly improve user experience. Here are some functionalities to keep in mind:

- Intuitive control layout for ease of use

- Variable speed settings for different tasks

- Integrated safety features to prevent accidents

- Regular maintenance alerts for optimal performance

Maintenance Tips for Optimal Performance

Ensuring the longevity and efficiency of your machinery requires consistent care and attention. Adopting best practices for upkeep can significantly enhance functionality and prevent unexpected issues. By focusing on key aspects of maintenance, you can achieve peak performance and extend the lifespan of your equipment.

Regular Inspections: Conduct frequent checks of vital components to identify wear or damage early. Inspect belts, filters, and fluids to ensure everything operates smoothly. Address any discrepancies promptly to avoid larger problems down the line.

Fluid Maintenance: Keeping fluids at optimal levels is crucial for efficient operation. Regularly change engine oil and hydraulic fluids as per the recommended schedule. This not only helps in maintaining performance but also protects the engine from potential damage.

Blade Care: For machinery equipped with cutting elements, sharp blades are essential for effective performance. Regularly inspect and sharpen blades to ensure clean cuts, which reduces strain on the engine and improves overall efficiency.

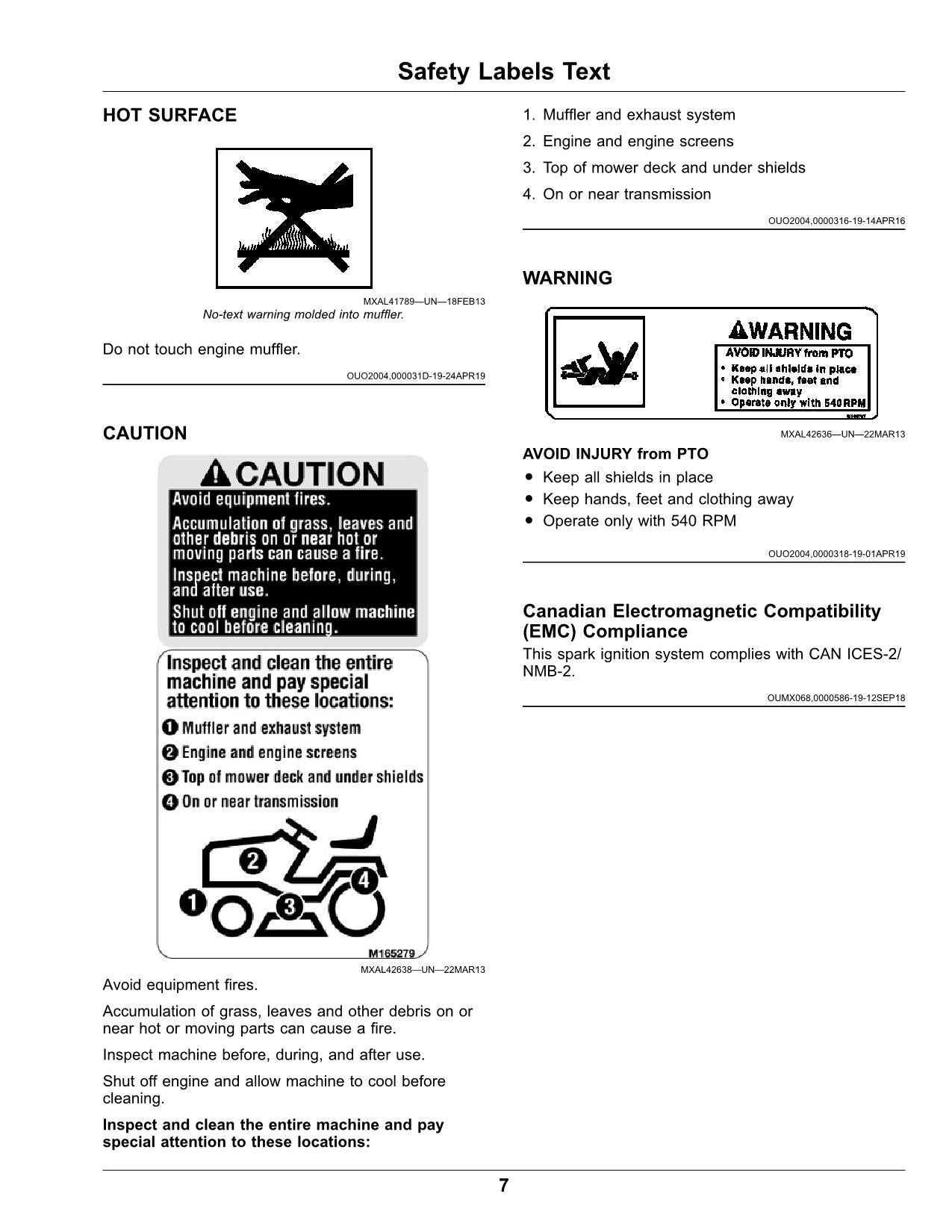

Cleaning and Debris Removal: Remove dirt and debris from the equipment after use. Accumulation of grass, leaves, or mud can hinder performance and lead to overheating. A clean machine operates more effectively and is less prone to mechanical failures.

Storage Practices: When not in use, store your equipment in a dry, sheltered area to protect it from the elements. This helps prevent rust and deterioration, ensuring it remains in good working condition when you need it.

Common Troubleshooting Procedures Explained

Understanding typical issues that may arise with equipment is essential for maintaining optimal performance. This section outlines effective strategies for diagnosing and resolving frequent complications that users may encounter. By familiarizing oneself with these troubleshooting techniques, operators can ensure smoother operation and prolong the lifespan of their machinery.

1. Engine Won’t Start: If the engine fails to ignite, check the battery charge and connections. Ensure that the ignition switch is in the correct position and that the fuel supply is adequate. If these components are functioning properly, inspect the starter motor for any faults.

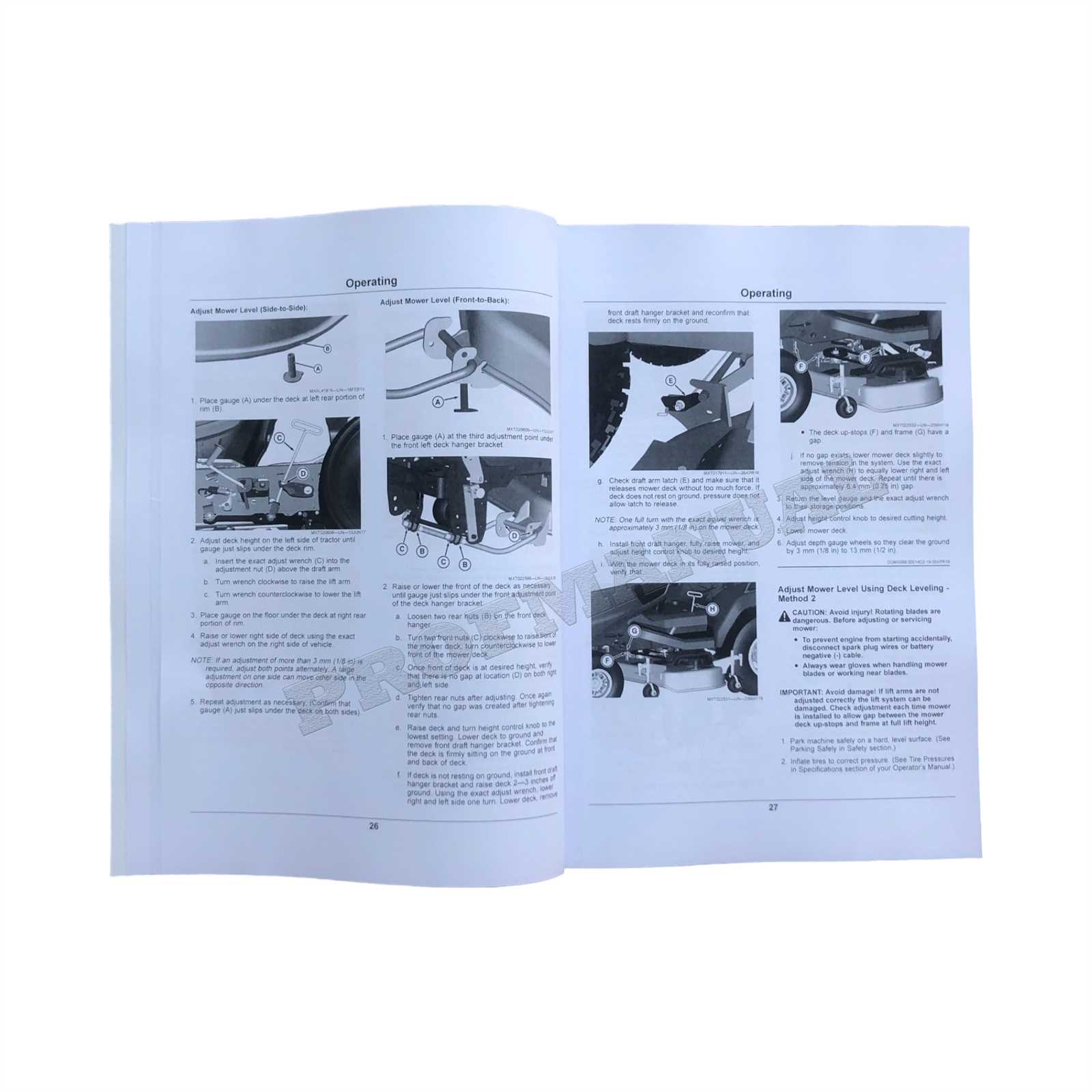

2. Uneven Cutting: When the cutting performance is inconsistent, verify that the blades are sharp and free from debris. Additionally, check the tire pressure to ensure proper leveling and inspect the cutting height settings to match the intended use.

3. Overheating: An overheating engine can be caused by low coolant levels or blocked air intake. Regularly inspect the cooling system and clean any obstructions to maintain optimal airflow. If the problem persists, consider examining the thermostat and water pump.

4. Hydraulic Issues: If hydraulic functions are sluggish or unresponsive, inspect the fluid levels and look for leaks in the hoses and connections. Additionally, ensure that the hydraulic filter is clean to prevent flow restrictions.

Implementing these troubleshooting procedures can significantly enhance the reliability and functionality of the equipment. Regular maintenance and prompt attention to issues will contribute to efficient performance over time.