Efficiently managing your outdoor equipment requires a clear understanding of its various components and functionalities. Knowing how to properly maintain and troubleshoot your machine can save time and extend its lifespan. This guide aims to help you navigate through the essential aspects of your equipment, ensuring it performs at its best for years to come.

Maintenance tips and regular care routines are key factors in ensuring longevity and optimal operation. Whether it’s engine upkeep, blade sharpening, or other routine adjustments, understanding these procedures can make a significant difference. This section will walk you through important steps to keep your equipment in top shape.

Proper handling and care are also crucial when it comes to achieving peak performance. By following the recommended guidelines, you’ll be able to enhance both the safety and efficiency of your equipment, ensuring smooth and trouble-free operation during each use.

Understanding the Features of John Deere X540

Exploring the capabilities of this advanced machine reveals a blend of power, durability, and precision. It is designed to provide users with an efficient and reliable solution for a wide range of tasks, making it a versatile tool in both residential and commercial settings.

Enhanced Performance: The equipment boasts a robust engine, ensuring that heavy workloads are managed effortlessly. Its smooth operation across various terrains highlights its adaptability, making it suitable for different types of environments.

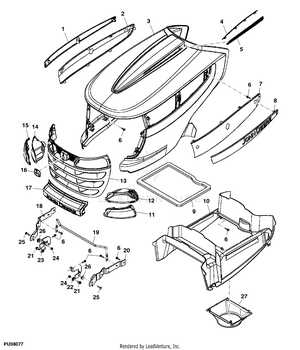

Advanced Cutting System: Equipped with a precision cutting deck, this model delivers an even and clean finish. Users can expect high-quality results whether managing large fields or smaller lawns, thanks to its efficient cutting mechanism.

Comfortable Design: Operator comfort is a key feature,

Engine Specifications and Performance Capabilities

The engine plays a crucial role in delivering both power and efficiency. It is designed to meet the demands of various terrains, ensuring reliability and consistent performance. In this section, we will explore the key specifications that contribute to the overall functionality of the engine, highlighting its capabilities in terms of power output, fuel efficiency, and operational capacity.

Key Engine Specifications

- Displacement: The engine’s displacement is optimized to provide a balance between power and fuel economy, making it suitable for both light and heavy-duty tasks.

- Cooling System: A liquid cooling system ensures that the engine maintains optimal temperatures even during prolonged use, preventing overheating and enhancing longevity.

- Fuel Type: The engine is designed to operate on standard-grade fuel, offering flexibility and ease of refueling in various environments.

Performance Features

- Torque Output: High torque

Maintenance Tips for Prolonging Equipment Life

Regular upkeep of machinery ensures its durability and optimal performance over time. By adhering to a consistent maintenance routine, users can prevent wear and tear, reduce the risk of unexpected failures, and extend the lifespan of their equipment.

A well-maintained machine not only operates more efficiently but also saves costs on repairs and replacements. Below are key maintenance tips that can help keep your equipment running smoothly for years to come.

Tip Description Lubrication Ensure all moving parts are properly lubricated to reduce friction and prevent damage. Inspection Conduct regular visual inspections to identify any signs of wear, cracks, or loose components. Cleaning Safety Guidelines for Optimal Operation

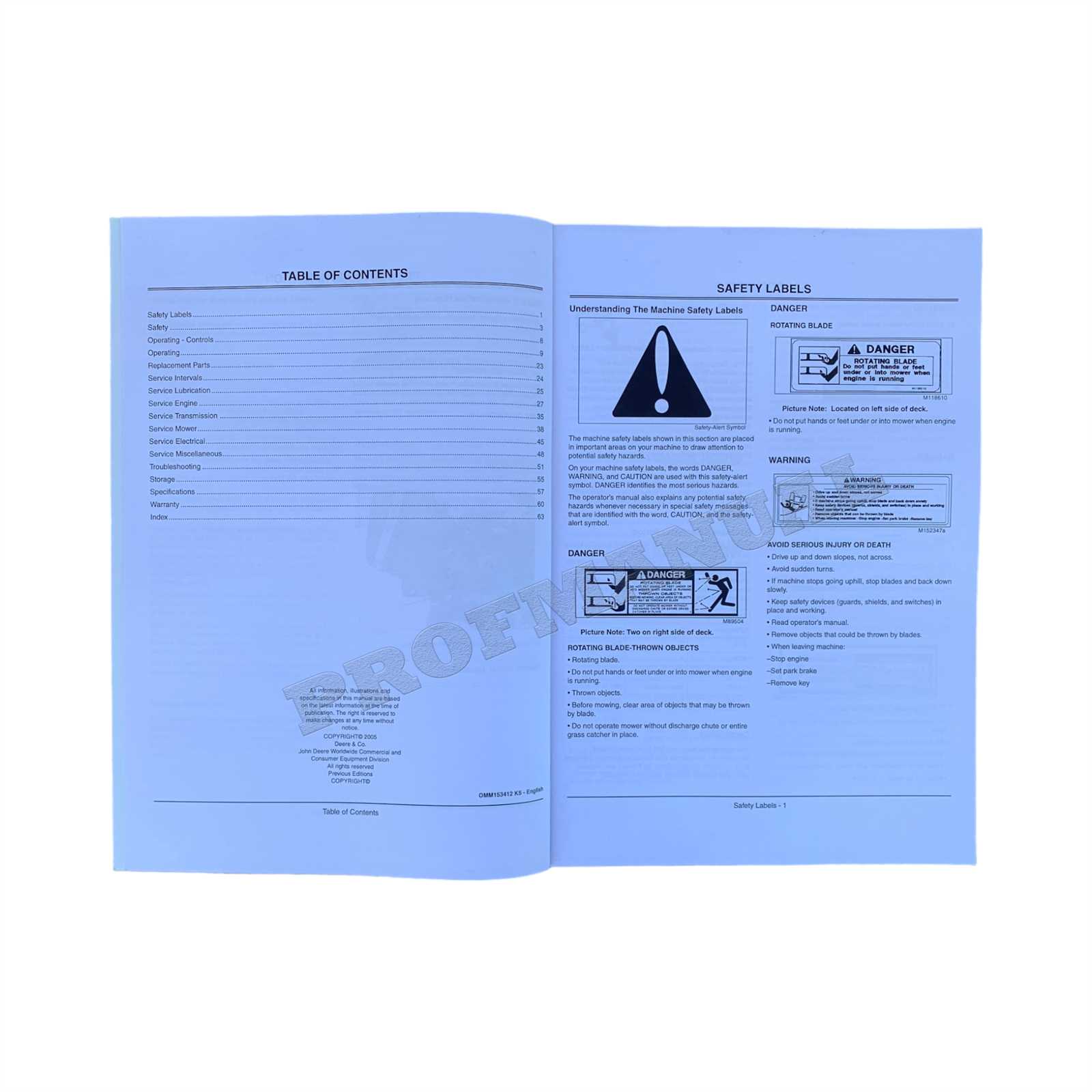

Ensuring safety during equipment use is essential for both operator protection and maintaining the longevity of the machine. By adhering to proper procedures, potential risks can be minimized, allowing for efficient and safe use. It is critical to understand the necessary precautions before and during operation to prevent accidents.

Wear appropriate protective gear at all times. Proper clothing, gloves, and eye protection will help reduce the risk of injury from flying debris or machine parts. Always inspect the equipment before use to ensure there are no visible damages or loose components that could affect functionality.

Be cautious of your surroundings, and never operate the machinery near children or pets. Ensure the work area is free of obstacles that could interfere with movement. Follow recommended operational speeds to maintain control and avoid sudden stops or turns, which could lead to accidents.

Regular maintenance is key to safe operation. Ensure all parts are functioning

Troubleshooting Common Issues with Your Lawn Tractor

Understanding how to address common mechanical and operational problems is crucial for keeping your garden equipment running smoothly. Regular maintenance and early identification of issues can save time and extend the life of your machine.

Engine Starting Problems

If the motor fails to start, the first step is checking the fuel level and quality. Ensure the battery is fully charged, and all electrical connections are secure. If the issue persists, the ignition system, such as the spark plug or wiring, may require inspection or replacement.

Uneven Cutting Performance

Uneven cutting can result from dull or damaged blades, improper deck height, or an uneven terrain. Make sure the blades are sharp and balanced. Also, adjust the mower deck to the correct height and inspect for any obstructions underneath.

Tip: Regular blade maintenance ensures optimal cutting efficiency and prevents long-term wear on your machine.