The efficient use of specialized machinery requires a clear understanding of its features and functionality. Proper care and regular adjustments ensure longevity and optimal performance of the equipment, whether used for landscaping, farming, or other purposes. This guide provides a detailed overview of essential aspects to consider for smooth and reliable operation.

In the following sections, you will find practical advice on setup, routine care, and troubleshooting. With these tips, users can maintain peak performance and address any common issues that may arise during operation, helping to avoid unnecessary downtime and repairs.

Whether you’re familiar with such machines or new to them, this resource will assist you in mastering the handling and upkeep of your equipment, ensuring its efficiency for years to come.

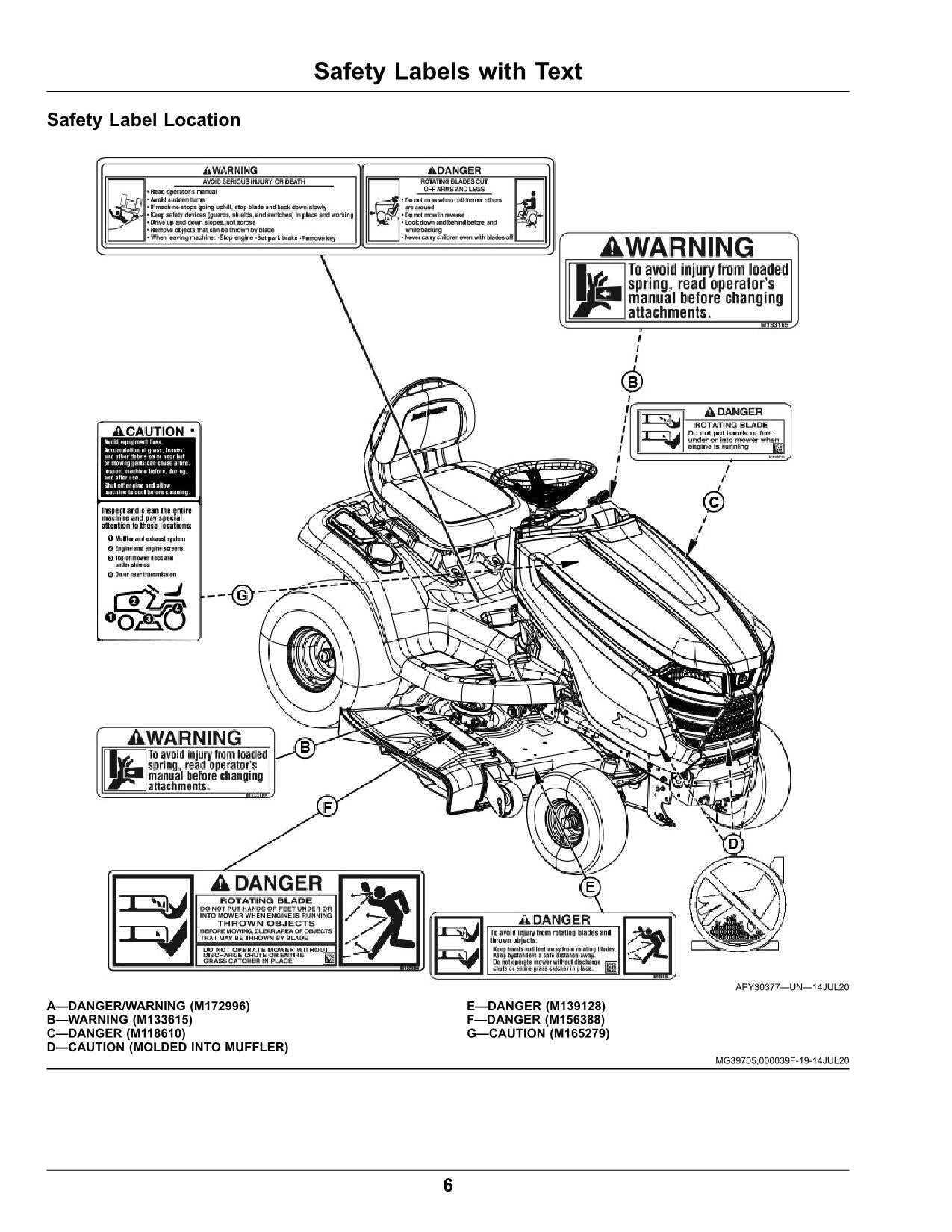

Understanding the Features of This Lawn Tractor

The lawn tractor in question offers a range of capabilities designed to provide a smooth and efficient lawn maintenance experience. Its design ensures ease of use, making it suitable for both beginners and experienced operators. This section explores the key elements that enhance its functionality and convenience.

- Powerful Engine: This machine is equipped with a robust engine, ensuring that it can handle various tasks, from light mowing to more demanding terrain.

- Durable Construction: The solid frame and high-quality materials guarantee long-term performance and resilience under regular use.

- Easy Operation: Simple controls allow the operator to maneuver the vehicle with precision, making it a user-friendly option.

- Comfortable Seating: Ergonomically designed seating enhances comfort, especially during extended periods of work.

- Efficient Cutting System: The mower’s cutting system provides a clean

Maintenance Tips for Longevity

Ensuring the long-term durability of your equipment requires consistent care and attention. Regular upkeep not only improves performance but also extends the lifespan of your machine, minimizing the need for costly repairs.

- Clean frequently: Make sure to remove debris and dirt from key areas, especially around the engine and moving parts. This helps prevent damage and maintains efficiency.

- Lubricate moving parts: Apply the appropriate lubricants to reduce friction and wear, ensuring smoother operation over time.

- Inspect filters and fluids: Regularly check and replace air, oil, and fuel filters as needed. Also, keep fluids topped up and change them according to the recommended intervals.

- Check tire pressure: Properly inflated tires are essential for optimal performance and to avoid unnecessary wear on the tires and the machine itself.

- Efficient Operation for Optimal Performance

Ensuring smooth and effective operation of your equipment is key to achieving the best results and prolonging its lifespan. By following a few core principles, you can maximize the machine’s potential while reducing wear and tear.

First, always maintain a consistent pace when using the equipment. Avoid sudden stops and starts, as they can put unnecessary strain on the engine and other components. Instead, operate at a steady, moderate speed that allows for both precision and power.

Second, regular maintenance is crucial. Keeping components clean and properly lubricated will prevent unexpected breakdowns and help the machinery run efficiently. Pay close attention to key areas such as filters, belts, and blades, ensuring they are in optimal condition at all times.

Finally, adjust settings based on the specific task at hand. Whether you are tackling a large open area or navigating tighter spaces, optimizing the machine’s configuration for the environment can significantly improve performance and fuel efficiency.