Proper care and understanding of machinery are crucial for optimal performance. This segment is dedicated to providing detailed instructions and insights on how to effectively utilize your device. By familiarizing yourself with the operational guidelines, you can ensure the longevity and efficiency of your equipment.

In this section, we will explore essential practices for maintaining and operating your machine safely. From preparation to regular maintenance, every step is covered to help you get the most out of your equipment. These recommendations are designed to enhance your experience and prevent common issues that may arise during usage.

Whether you are new to this type of equipment or have previous experience, the following guidance will support you in managing your tasks with ease. Understanding these key points will not only improve the lifespan of your machine but also ensure a safer and more effective working environment.

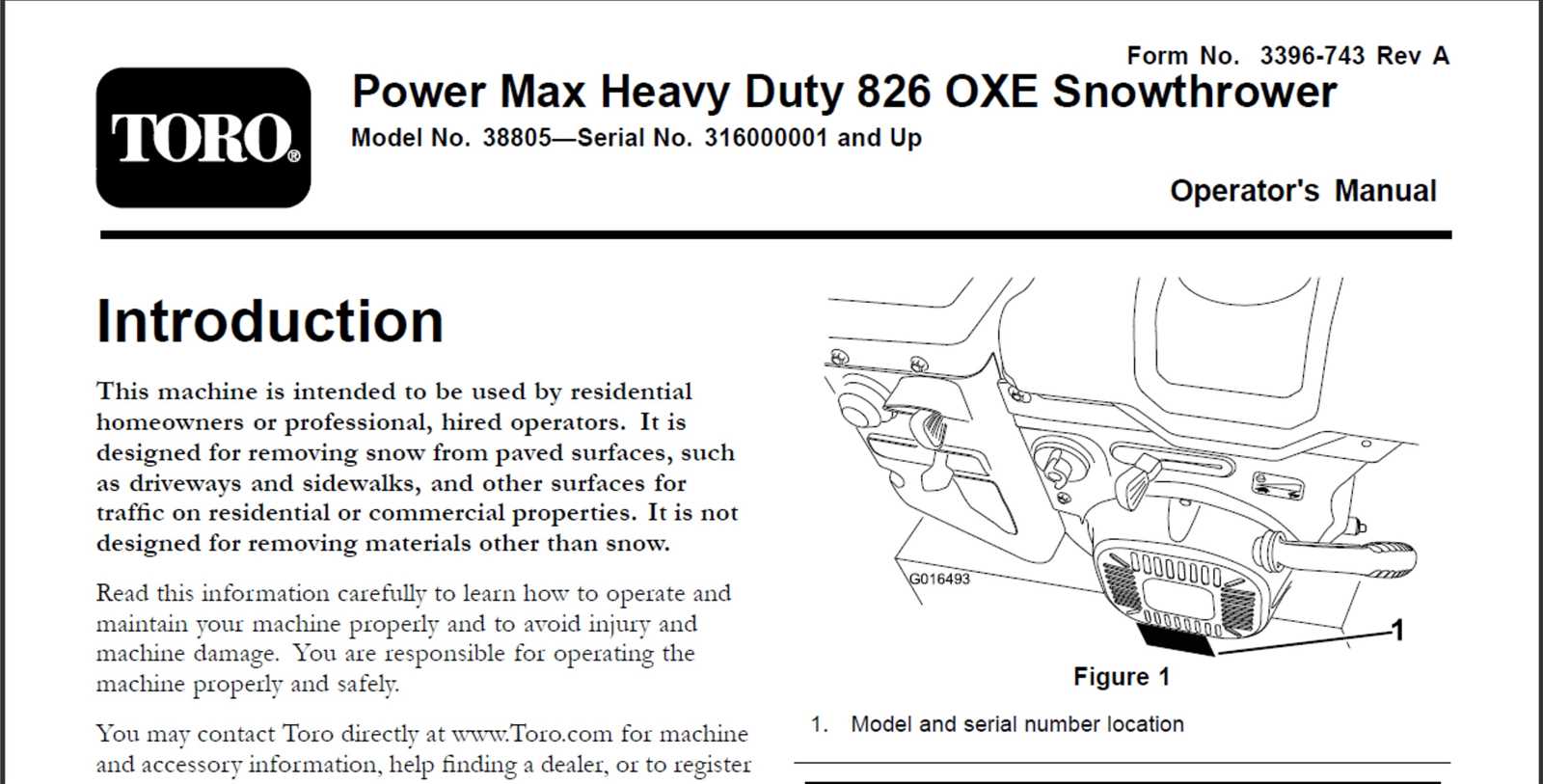

Understanding Snow Removal Equipment Components

In order to achieve optimal performance during winter months, it is crucial to be familiar with the various parts that make up snow-clearing machinery. Knowing the purpose of each element allows for better maintenance and troubleshooting, ensuring efficient operation when it’s needed the most.

Main Elements and Their Functions

- Engine Unit: This part powers the entire mechanism, providing the necessary force to move and clear heavy snow.

- Auger Assembly: A key element that rotates to gather and break up snow, directing it towards the discharge chute.

- Discharge Chute: Responsible for ejecting the collected snow away from the cleared path, adjustable to control the direction and distance.

- Control Panel: Houses all the controls for operating and adjusting the machine, including speed, direction, and chute angle.

- Transmission System: Connects the power from the engine to the wheels, enabling smooth movement and maneuverability.

Importance of Regular Maintenance

- Inspection: Regularly check for wear and tear on key components to avoid breakdowns during critical times.

- Lubrication: Ensure that all moving parts are properly lubricated to prevent friction and damage.

- Tightening Bolts: Vibration can loosen bolts over time, so it’s important to tighten them periodically to maintain structural integrity.

- Clearing Blockages: Always clear any blockages in the chute and auger to prevent damage and maintain efficiency.

Understanding the different components and their roles will not only improve your ability to operate the equipment effectively but also extend its lifespan by allowing for proper upkeep and timely repairs.

Maintenance Tips for Optimal Performance

Ensuring the reliable operation of your equipment during challenging weather conditions requires regular upkeep. By following essential maintenance practices, you can extend its lifespan and enhance its efficiency. Below are some key tips to help maintain your machine in top condition throughout the season.

| Maintenance Task | Frequency | Description |

|---|---|---|

| Check Fluid Levels | Before Each Use | Regularly inspect and top off all necessary fluids to ensure smooth operation. This includes lubricants and fuel, which are crucial for optimal performance. |

| Inspect Moving Parts | Weekly | Examine all moving components for wear and tear. Replace or repair any damaged parts to prevent potential breakdowns during heavy use. |

| Clean After Use | After Each Use | Thoroughly clean the equipment after every use to remove debris and prevent buildup that could lead to malfunction. |

| Sharpen Blades | Monthly | Keep the blades sharp to ensure efficient operation. Dull blades can reduce effectiveness and increase strain on the motor. |

| Store Properly | End of Season | At the end of the season, store your machine in a dry place and cover it to protect it from dust and moisture. Consider draining fuel to prevent residue buildup. |

Following these guidelines will help you maintain your machine’s performance and readiness for use whenever needed. Consistent care and attention to detail are key to its longevity and effectiveness.

Common Troubleshooting for Efficient Operation

Efficient functionality often depends on timely identification and resolution of various issues. When operating equipment, certain challenges may arise, impacting its overall performance. This section provides practical tips to diagnose and address common problems that can hinder optimal functioning.

Identifying Performance Issues

If you notice any inconsistencies in operation, such as reduced efficiency or unusual behavior, it is crucial to inspect the system thoroughly. Start by checking key components like the power source, fuel system, and moving parts. Ensuring that these elements are in good condition can help prevent more significant issues. Regular maintenance and cleaning are also essential for preventing build-up that could lead to decreased performance.

Addressing Mechanical Challenges

Mechanical problems are another common obstacle. If the machine fails to operate correctly or makes unusual noises, it may indicate issues with the internal components. Inspect the belts, blades, and auger to identify any wear or damage. Replacing worn-out parts promptly and lubricating moving components will help maintain smooth operation. Always refer to safety guidelines when performing maintenance tasks to avoid potential hazards.