This section provides essential information for users of a compact agricultural vehicle. Understanding the fundamental features and maintenance requirements ensures optimal performance and longevity of the equipment.

Utilizing this guide, operators can familiarize themselves with crucial aspects, including safety protocols, regular upkeep tasks, and troubleshooting techniques. Proper comprehension of these elements contributes to effective usage and minimizes the likelihood of operational issues.

Moreover, the information contained within is designed to enhance the user experience, enabling individuals to maximize the capabilities of their machinery. By adhering to the recommended practices, users can achieve greater efficiency and productivity in their tasks.

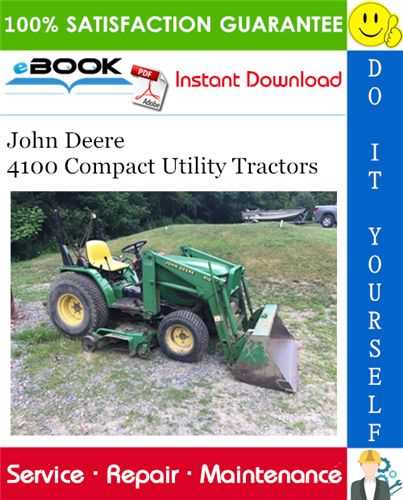

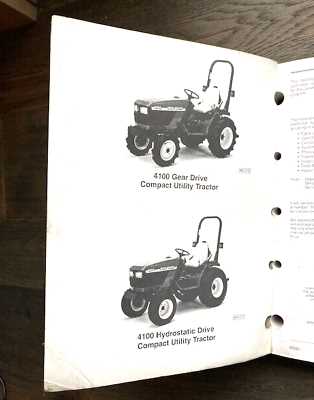

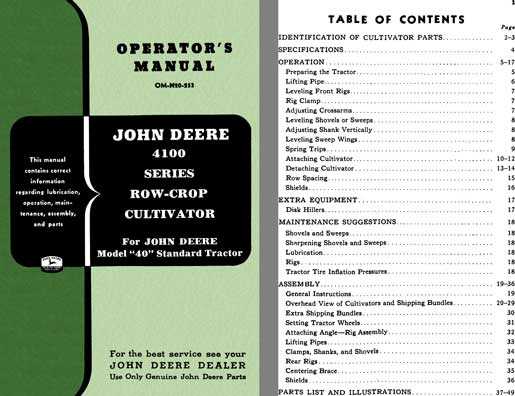

John Deere 4100 Overview and Features

This compact utility vehicle is designed for a variety of tasks, making it a versatile choice for both residential and commercial applications. Its efficient engine and reliable performance cater to users looking for power and agility in a small package.

Notable characteristics include a user-friendly interface, allowing easy navigation of controls. This machine also offers enhanced maneuverability, which is crucial for working in tight spaces. Additionally, its robust construction ensures durability and longevity, even under demanding conditions.

| Feature | Description |

|---|---|

| Engine Type | Efficient diesel engine for optimal performance |

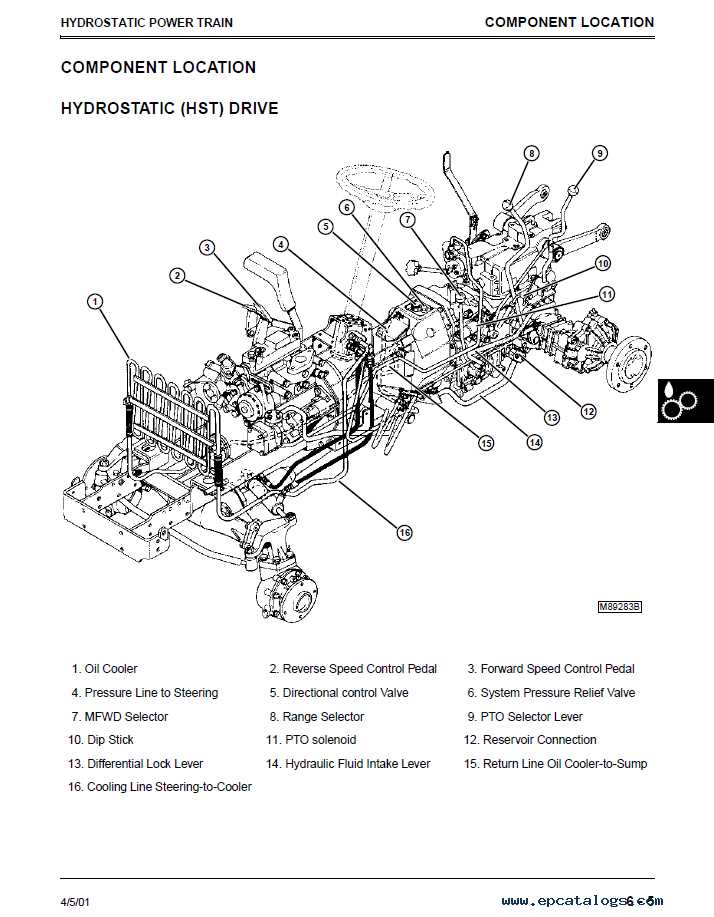

| Transmission | Smooth hydrostatic transmission for easy handling |

| Hydraulic System | Powerful hydraulics for lifting and operating implements |

| Compact Size | Ideal for maneuvering in confined areas |

| Operator Comfort | Ergonomic seating and control layout |

Maintenance Guidelines for Your Tractor

Regular upkeep is essential for ensuring optimal performance and longevity of your agricultural equipment. Adhering to proper maintenance practices not only enhances functionality but also reduces the likelihood of unexpected breakdowns. Below are key recommendations to keep your tractor in excellent condition.

- Fluid Checks:

- Inspect engine oil and replace it according to the manufacturer’s specifications.

- Check coolant levels regularly to prevent overheating.

- Monitor hydraulic fluid to ensure smooth operation of implements.

- Air Filters:

- Clean or replace air filters periodically to maintain optimal airflow.

- Inspect for dirt and debris buildup that can affect engine performance.

- Tire Maintenance:

- Check tire pressure frequently to ensure stability and fuel efficiency.

- Inspect tread for wear and replace tires as necessary to ensure safety.

- Belt and Hose Inspection:

- Examine belts for signs of wear, fraying, or damage.

- Check hoses for leaks, cracks, or other issues that may lead to failures.

- Battery Care:

- Ensure battery terminals are clean and connections are secure.

- Test battery charge regularly and replace it if necessary.

By following these maintenance guidelines, you can extend the life of your equipment and ensure it operates efficiently throughout its service. Regular attention to these areas will help you avoid costly repairs and downtime.

Common Issues and Troubleshooting Tips

This section addresses frequently encountered challenges and provides practical solutions for efficient operation. Understanding these common problems can help enhance performance and extend the lifespan of your equipment.

Engine Performance Issues

One of the typical concerns involves engine performance. Symptoms such as rough idling or difficulty starting may arise due to various factors, including fuel quality or air intake blockages. Regular maintenance checks can mitigate these issues.

Hydraulic System Malfunctions

Hydraulic systems are vital for functionality, yet they may experience leaks or pressure loss. Inspecting hoses and connections regularly can help identify potential leaks early and ensure optimal performance during operations.