Operating machinery efficiently requires understanding its components and functions. This guide provides essential information to help users familiarize themselves with their machine’s capabilities and maintenance requirements. Whether you’re preparing for long-term use or simply seeking to enhance daily performance, this resource will offer valuable insights.

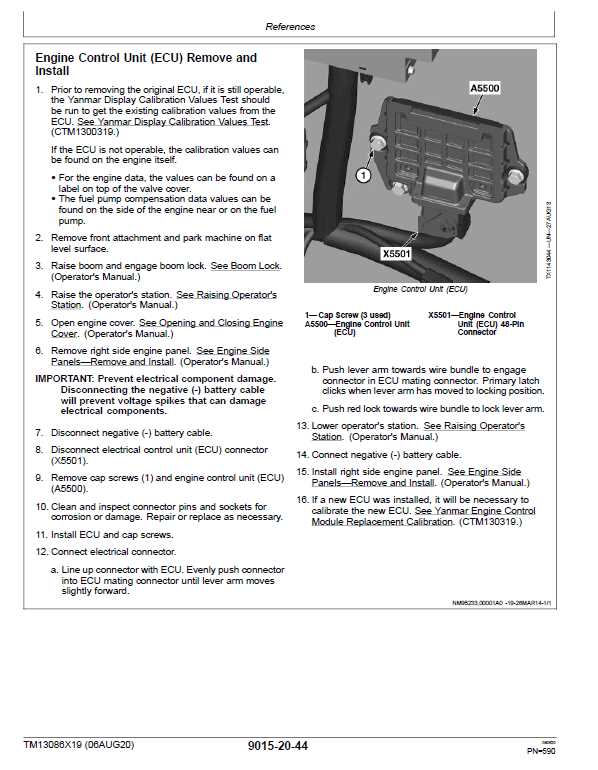

Proper care and routine checks are key to maximizing the lifespan of your equipment. In this guide, you’ll find detailed instructions for performing maintenance tasks and troubleshooting common issues. Ensuring optimal performance is crucial, and the following sections will outline step-by-step procedures to keep your machine in excellent condition.

Operating and Maintenance Guidelines for Compact Track Loader

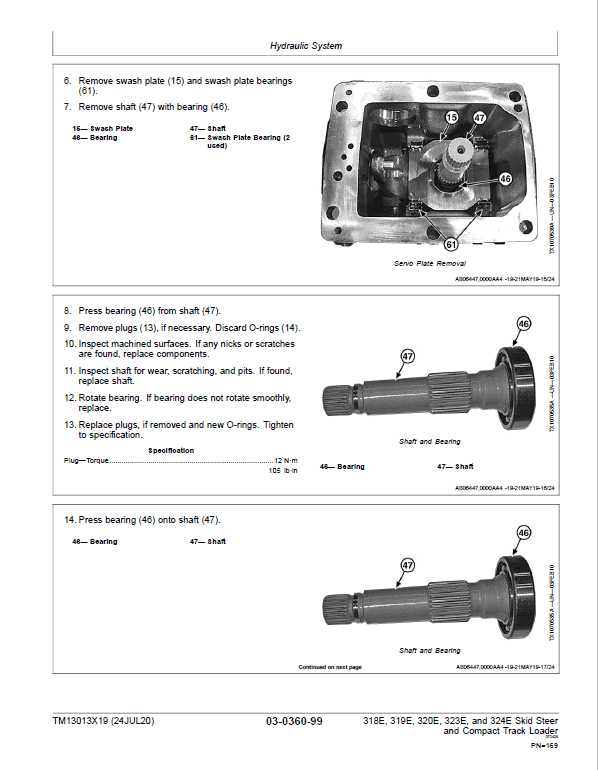

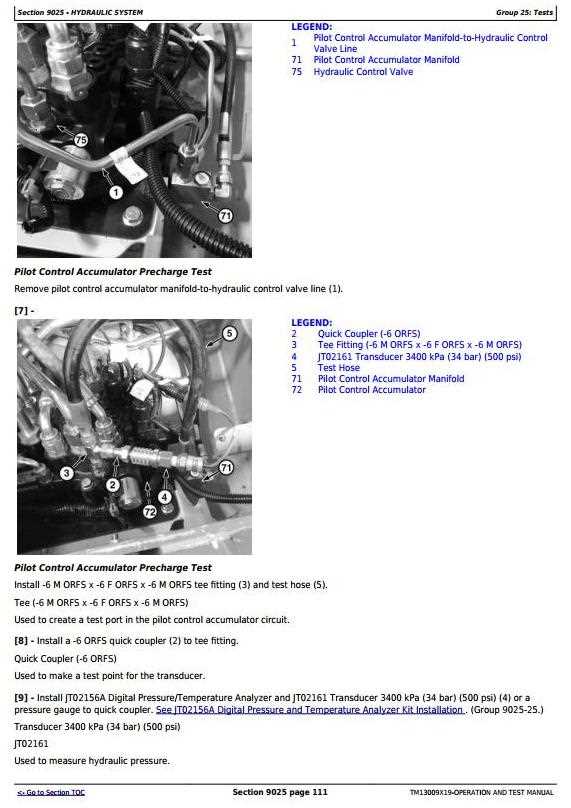

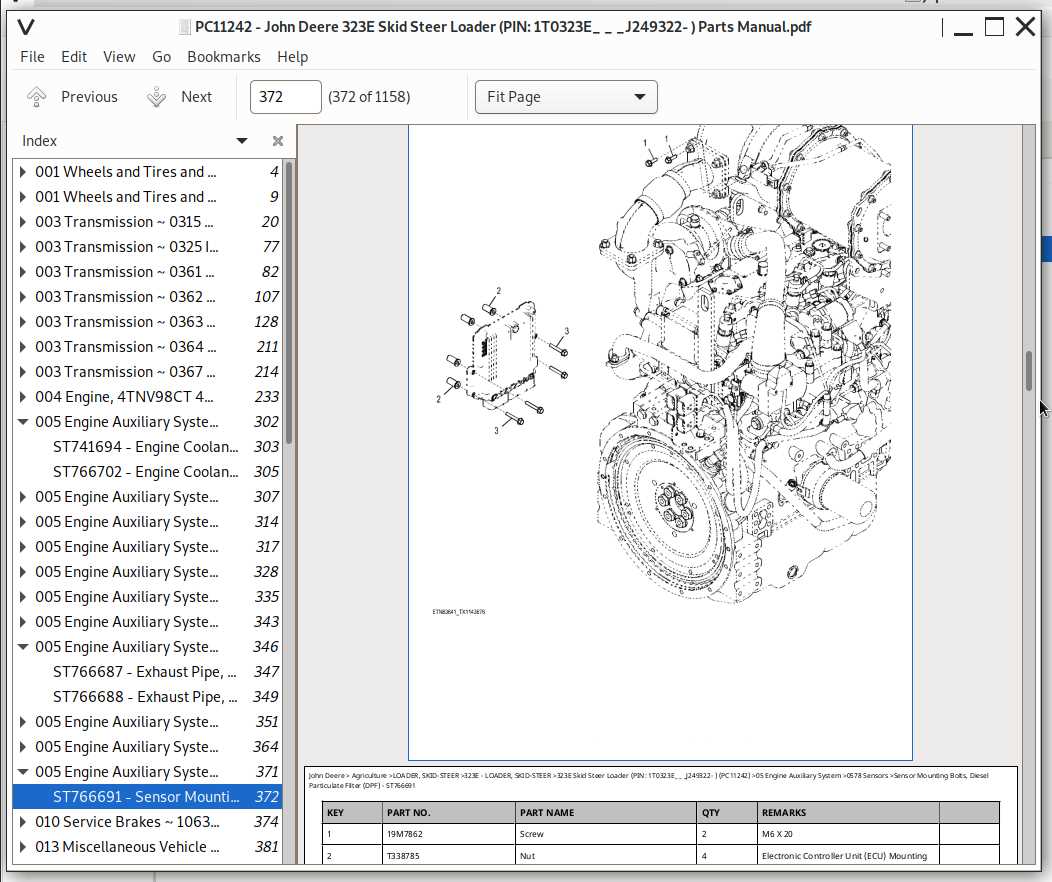

To ensure the longevity and efficiency of your compact track loader, it is essential to follow proper operational and maintenance practices. This equipment, designed for heavy-duty tasks, requires regular attention to both its mechanical systems and overall performance to guarantee reliable service. Understanding the key principles of operation and routine care can significantly reduce downtime and extend the lifespan of your machine.

Before starting the engine, always conduct a thorough pre-operation inspection. Check the fluid levels, including hydraulic oil and coolant, and ensure all safety mechanisms are in place. Regularly inspect the tracks for wear and debris, as this can affect traction and stability during operation. Maintaining clean filters and monitoring the condition of belts and hoses will also prevent unexpected breakdowns.

Routine maintenance should include regular oil changes, lubrication of moving parts, and the inspection of electrical systems. Keeping the cooling system free from dirt and obstructions is crucial to prevent overheating. Additionally, follow the recommended service intervals for replacing parts

Safety Procedures for Compact Track Loader

Ensuring the safe operation of your equipment is essential for both the operator and those in the surrounding area. Following the recommended safety practices can prevent accidents and reduce the risk of injury during routine tasks.

General Safety Guidelines

Before operating the machine, conduct a thorough inspection to ensure all systems are functioning correctly. Always be aware of your surroundings, including other workers and potential hazards. Use personal protective equipment (PPE) and follow the designated safety protocols.

Operating and Maintenance Precautions

When performing maintenance, ensure the equipment is turned off and properly secured to avoid accidental movement. Regularly check fluid levels, tire pressure, and other critical components to maintain optimal performance. Adhere to load limits to prevent instability or tipping during operation.

| Task | Safety Measure |

|---|---|

| Pre-operation Inspection | Check for damage, leaks, and proper fluid levels. |

| During Operation | Maintain clear visibility and avoid operating near people or obstacles. |

| Post-operation Shutdown |