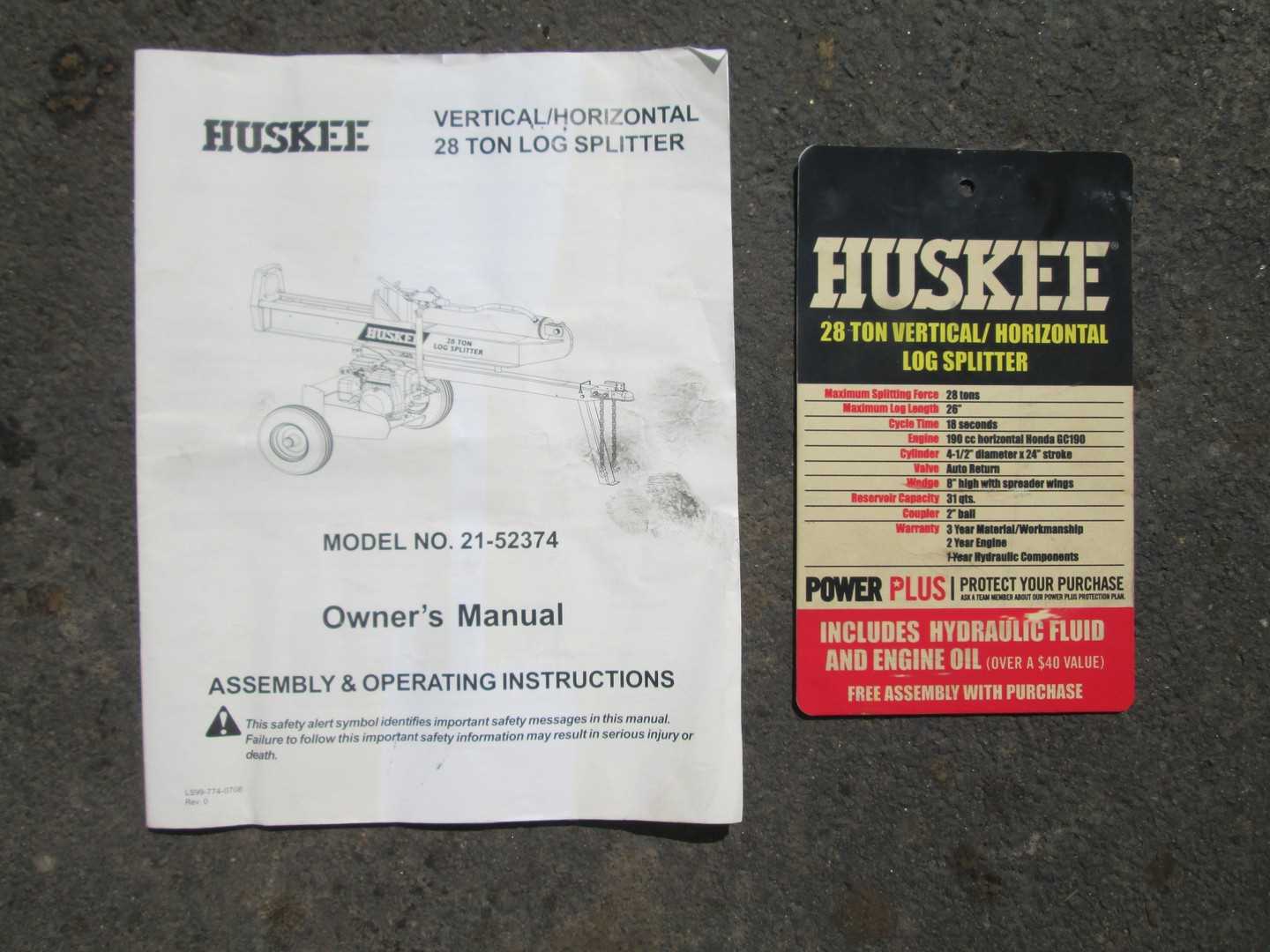

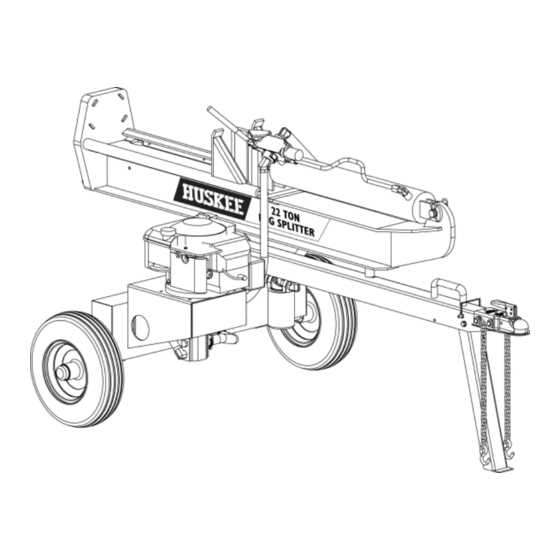

In this guide, you will find essential instructions for the proper and safe use of a powerful machine designed to split wooden materials. Whether you are preparing firewood or handling other similar tasks, understanding the

Essential Safety Guidelines for Using a Log Splitter

When operating powerful equipment, ensuring safety is a top priority. Proper precautions help prevent accidents and injuries, making the work process more efficient and secure. Below are key recommendations to follow when handling wood processing machinery.

- Always wear protective gear, including gloves, safety glasses, and sturdy footwear.

- Ensure the work area is clear of obstacles and bystanders before starting any operation.

- Inspect the equipment for damage or wear before use, paying close attention to moving parts.

- Never operate the machinery when tired or under the influence of alcohol or medications.

- Use both hands to control the machine, keeping all body parts away from moving components.

- Disconnect the power source when cleaning, adjusting, or repairing the device.

- Keep children and pets away from the workspace at all times.

By adhering to these essential safety practices, operators can reduce the risk

Regular Maintenance for Optimal Performance

Consistent upkeep is crucial to ensure that your equipment operates at its best. By performing regular checks and following a maintenance schedule, you can extend the lifespan of your machine

Troubleshooting Common Log Splitter Issues

When your equipment experiences difficulties, it can disrupt your tasks significantly. Understanding how to identify and resolve these problems ensures smooth operation and prevents downtime. Below are some common malfunctions and tips to help you get your machine back to working condition.

Hydraulic System Problems

If you notice a drop in performance or inconsistent pressure, the hydraulic system might be to blame. Check for low fluid levels or possible air trapped in the lines. Make sure the fluid is clean and free of debris, as contamination can lead to issues with power delivery. Additionally, inspect the hoses and seals for any leaks or damage.

Engine Won’t Start

An engine that refuses to start is often linked to fuel, spark, or air intake problems. First, verify that there’s enough fuel and that the fuel isn’t stale. Ensure the air filter is clean, and check the spark plug for dirt or wear. If necessary, replace faulty components to restore functionality. Regular maintenance will help avoid this issue in the future.