Maintaining machinery in optimal condition is crucial for ensuring long-term performance and reliability. This section offers detailed insights into how to make the most of your equipment, highlighting key aspects that contribute to its efficient operation and upkeep. Whether you are new to handling such machinery or looking for advanced tips, this guide aims to cover all essential aspects comprehensively.

In the following paragraphs, you will find useful advice on routine maintenance, operational guidelines, and troubleshooting techniques that will help you keep the equipment running smoothly. Emphasis is placed on providing clear, concise information that is easy to follow, enabling you to maximize productivity while minimizing potential issues.

Adhering to these recommendations will not only enhance the functionality of your machine but also extend its lifespan, ensuring that it continues to serve you effectively for years to come. By following these best practices, you can avoid common pitfalls and achieve a higher level of performance and safety during operation.

Essential Maintenance Tips for Your Equipment

Regular upkeep is crucial for ensuring the longevity and optimal performance of any machinery. By following a few simple guidelines, you can prevent unexpected breakdowns and extend the lifespan of your device. The key is to establish a routine that covers all major components, from the engine to the cutting deck, and address issues before they become significant problems.

| Maintenance Task | Frequency | Details |

|---|---|---|

| Engine Oil Check | Before Each Use | Verify the oil level and top up as necessary. Regularly change the oil based on usage hours to ensure smooth engine performance. |

| Air Filter Cleaning | Monthly | Inspect the air filter for dust and debris. Clean or replace it to maintain proper airflow and prevent engine strain. |

| Blade Sharpening | Every 25 Hours | Check the cutting blades for dullness or damage. Sharpen or replace them as needed for clean cuts and reduced strain on the motor. |

| Hydraulic System Inspection | Annually | Inspect hydraulic hoses and connections for leaks or wear. Replace any damaged parts to prevent system failure. |

| Battery Maintenance | Every 6 Months | Ensure the battery terminals are clean and secure. Check the voltage and recharge if necessary to avoid starting issues. |

By adhering to these basic guidelines, you can significantly reduce downtime and maintain your machine in peak condition throughout the season. Regular maintenance not only enhances performance but also safeguards your investment for years to come.

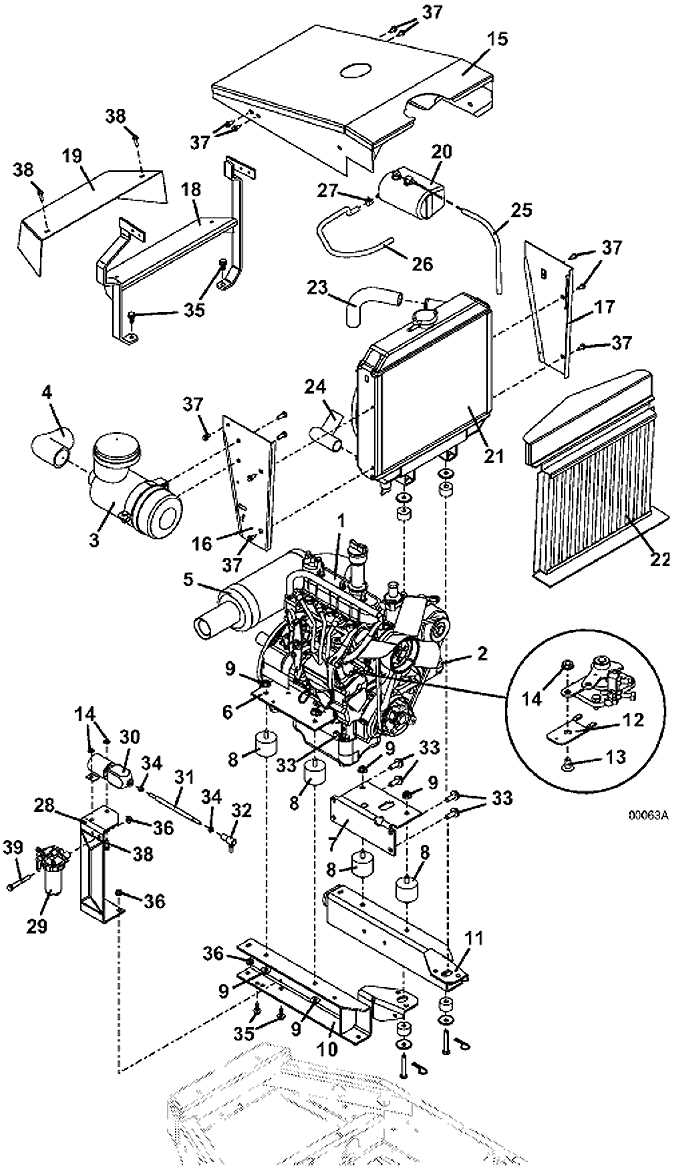

Routine Engine Care and Cleaning

Consistent upkeep of the engine is essential for ensuring its reliable performance and extending its lifespan. Regular maintenance tasks such as cleaning and inspection help in identifying potential issues before they escalate, keeping the equipment running smoothly.

Cleaning the Exterior: Begin by removing any accumulated dirt, grass, or debris from the engine surface. Use a soft brush or a compressed air blower for this purpose, making sure to avoid water, which could damage sensitive components.

Inspecting the Air Filter: The air filter plays a crucial role in preventing dust and particles from entering the engine. Check its condition regularly and clean or replace it as needed to ensure optimal airflow.

Checking the Cooling System: An efficient cooling system is vital for preventing the engine from overheating. Inspect the cooling fins and the fan for any obstructions and clean them to maintain proper airflow.

Fuel System Maintenance: Clean the fuel cap vent and ensure that the fuel lines are free from blockages. This prevents fuel flow interruptions and helps the engine to operate efficiently.

By incorporating these practices into your regular maintenance schedule, you can significantly improve the durability and performance of your equipment. Always follow safety guidelines and consult relevant resources when necessary.

Proper Blade Adjustment for Optimal Performance

Maintaining the correct blade alignment is crucial for ensuring smooth and efficient operation. The right adjustment not only improves the cutting quality but also prolongs the lifespan of the equipment. This section provides guidelines for achieving the ideal blade configuration to enhance overall functionality and performance.

First, always ensure that the blades are balanced and securely attached to the deck. Any imbalance can cause vibrations that affect the cutting efficiency and can lead to uneven results. To verify the balance, remove the blades and use a balance tool to check their alignment. If any discrepancies are found, it is essential to either sharpen the blades evenly or replace them if necessary.

Next, pay attention to the height setting. Adjusting the blades to the appropriate height for the type of grass being cut is vital. Too low a setting can scalp the lawn, while too high may result in uneven cuts and require more frequent mowing. A general recommendation is to start with a medium height setting and adjust incrementally based on the specific conditions of the lawn.

Finally, the angle of the blades should be carefully set to provide the best cutting action. Blades should be angled slightly upwards towards the front of the deck. This positioning allows for efficient lifting and cutting of the grass, leading to a cleaner and more uniform finish. Regularly check and adjust the blade angle to maintain optimal performance.

Troubleshooting Common Issues and Solutions

When operating machinery, encountering issues is not uncommon. Understanding the typical challenges and their resolutions can significantly enhance efficiency and extend the lifespan of the equipment. This section aims to provide insight into frequent problems and practical solutions, ensuring smooth operation.

Starting Problems: If the engine fails to start, first check the fuel level and battery charge. Ensuring that the fuel is clean and not contaminated is crucial. If the problem persists, inspect the ignition system for faults.

Uneven Cutting: This issue often arises from dull blades or improper height settings. Regularly sharpening blades and adjusting the cutting height according to the terrain can help maintain a consistent cut.

Overheating: Overheating can occur due to blocked air vents or low coolant levels. Regular cleaning of the air filters and monitoring coolant levels will prevent this issue. If overheating continues, it may indicate a more significant problem that requires professional attention.

Strange Noises: Unusual sounds during operation may signal loose parts or worn components. Conducting routine inspections to tighten bolts and replace worn parts can mitigate these issues.

Reduced Power: If you notice a decrease in performance, check for blockages in the air intake or exhaust systems. Cleaning these areas can restore the machine’s power output.

By being proactive and addressing these common concerns promptly, operators can ensure optimal performance and reliability of their equipment.