When it comes to operating essential maritime tools, understanding their functionality and maintenance is crucial for safety and efficiency. This section provides an in-depth overview of the features, operational guidelines, and troubleshooting techniques necessary for effective management.

Proper usage and care can significantly enhance performance and prolong the lifespan of the equipment. By familiarizing yourself with these aspects, you ensure not only the optimal operation but also contribute to a safer environment on board.

In the following sections, you will find detailed instructions and valuable tips to navigate common challenges. With this knowledge, you will be well-equipped to handle various situations confidently.

This section will explore the essential aspects of operating a marine hoisting device. It will provide insights into its mechanics, common uses, and the advantages it offers for efficient anchoring and mooring operations.

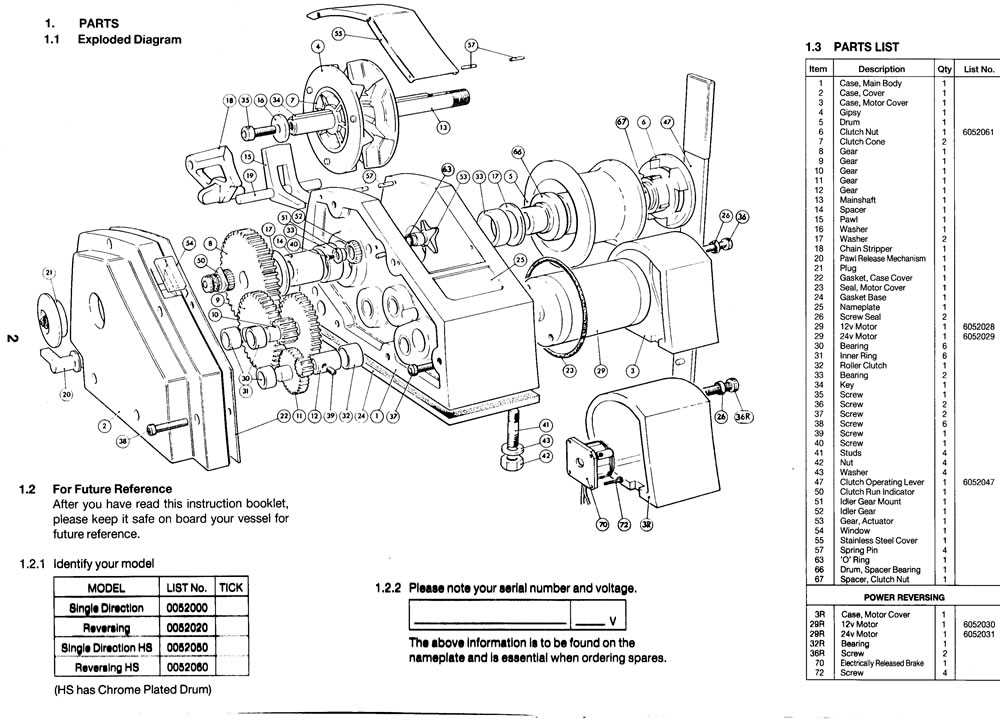

Key Components and Their Roles

- Motor: Powers the entire system for smooth operation.

- Drum: Where the line is wound, crucial for load management.

- Control System: Ensures user-friendly handling and safety features.

Operational Benefits

- Enhanced efficiency in raising and lowering anchors.

- Reduced physical effort for crew members.

- Increased safety during docking and anchoring processes.

Maintenance Tips for Optimal Performance

To ensure your equipment operates smoothly and efficiently over time, regular upkeep is essential. Consistent maintenance will help extend the lifespan of the system and prevent unexpected issues during operation. Below are some valuable practices to keep your machinery functioning at its best.

Regular Cleaning

Make sure to clean the device after each use, removing dirt, salt, and debris that could affect its functionality. A clean unit is less likely to suffer from corrosion and wear, making it more reliable in the long run.

- Use fresh water to rinse the exterior components.

- Check for any trapped particles and clean them out thoroughly.

- Wipe dry after washing to avoid moisture buildup.

Lubrication and Inspection

Proper lubrication of moving parts reduces friction and ensures smooth operation. In addition, regular inspections will help you detect any early signs of wear and tear.

- Lubricate gears and bearings according to the manufacturer’s recommendations.

- Inspect fasteners and bolts for tightness and secure them if necessary.

- Examine electrical connections to ensure they are clean and intact.

Troubleshooting Common Issues

When operating your device, various problems may arise that can hinder its performance. Recognizing these issues early and applying the appropriate solutions can ensure smooth operation and prolong its lifespan. Below, we will explore some frequent challenges and how to address them effectively.

Device Fails to Operate

If the system does not function as expected, there are several factors to consider. This is one of the most common issues users encounter, but it can often be resolved with simple steps:

- Check if the power source is connected properly and the battery is charged.

- Ensure that all wiring is intact and there are no loose connections.

- Inspect for any blown fuses or circuit breakers that may have been triggered.

Inconsistent Performance

If you notice fluctuations in operation, or if the device seems to work intermittently, the cause could be related to various technical aspects:

- Verify that the control panel is functioning correctly and all settings are appropriate.

- Lubricate any moving parts that may be causing friction or strain.

- Examine for signs of corrosion or dirt buildup on key components, which could disrupt smooth function.

By systematically addressing these common concerns, you can maintain optimal functionality and prevent long-term damage.