Understanding the proper handling and maintenance of your equipment is crucial for ensuring long-term reliability and optimal performance. This guide provides detailed insights into best practices for usage, helping you to maximize the lifespan of your machine and minimize issues along the way.

We’ll walk through various essential aspects, including regular care, troubleshooting tips, and techniques to ensure your equipment remains in top working order. By following the guidelines, you’ll be well-equipped to handle everyday challenges with ease.

From basic upkeep to more advanced functionalities, this manual offers valuable information for anyone looking to enhance their experience and achieve greater efficiency. Stay tuned for expert advice and proven methods that will keep your machine running smoothly for years to come.

Maintenance Procedures and Best Practices

Regular upkeep is crucial to ensure the long-term performance and reliability of any equipment. By following recommended care guidelines, users can prevent potential issues and extend the lifespan of their machines.

- Inspect all moving parts for wear and tear regularly.

- Lubricate essential components to reduce friction and prevent rusting.

- Check and clean air filters frequently to maintain optimal airflow.

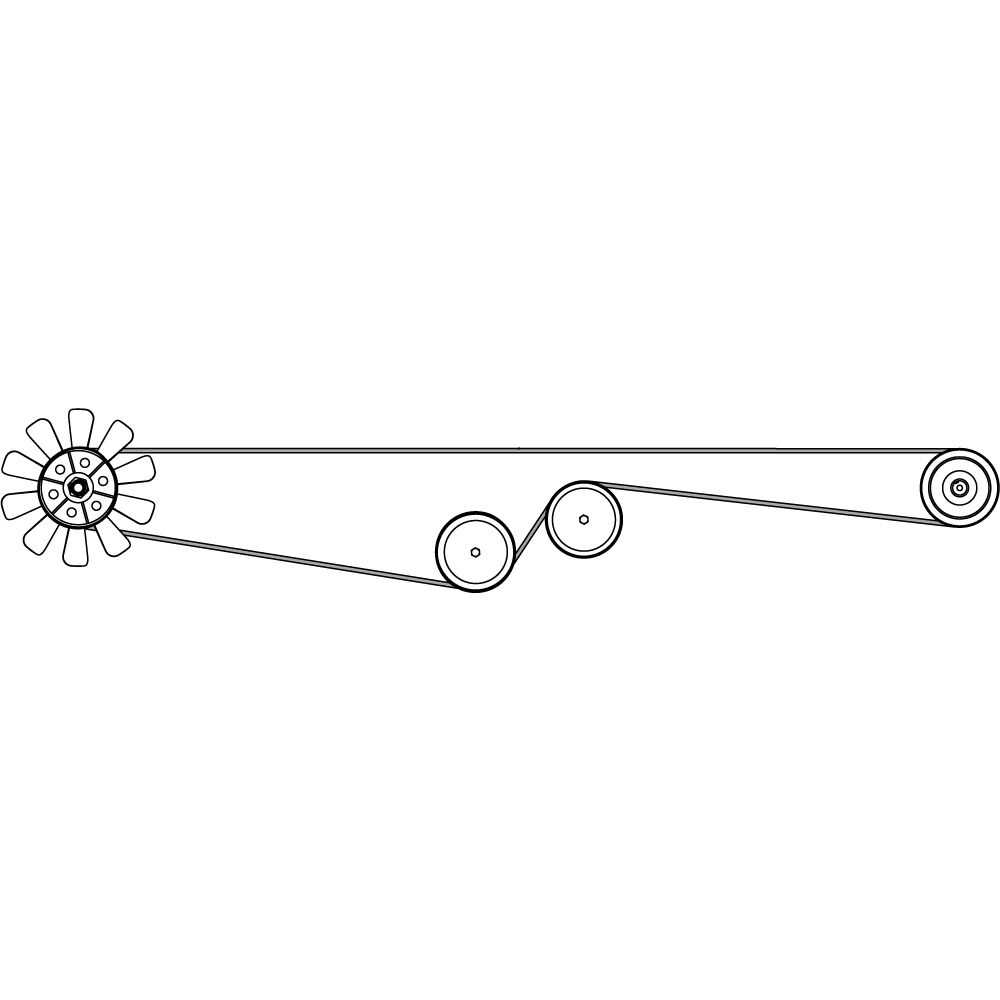

- Examine belts and replace them if any signs of damage appear.

- Ensure that tires are inflated to the proper pressure for smooth operation.

- Start by turning off the machine and allowing it to cool down before performing any maintenance.

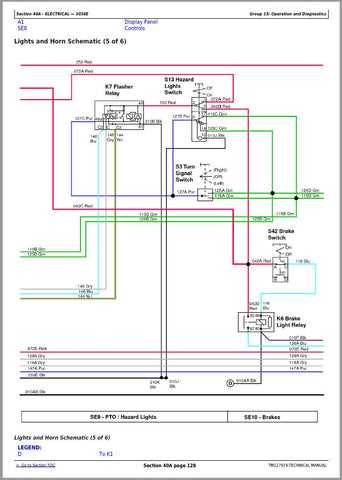

- Use appropriate tools and follow safety guidelines when checking internal components.

- Dispose of used oil and other fluids according to local environmental regulations.

- Schedule routine inspections with a qualified technician to identify any hidden problems early.

Troubleshooting Common Operational Issues

Ensuring the smooth performance of machinery can sometimes involve identifying and addressing minor issues that arise during operation. By understanding common operational challenges, users can quickly restore functionality and maintain optimal performance.

Engine Starting Difficulties

If the engine fails to start or starts with difficulty, there are several potential causes. Begin by inspecting the fuel system for any blockages or leaks. Check the spark plug for wear or dirt buildup, as it can interfere with proper ignition. Also, ensure that the battery is fully charged and all electrical connections are secure.

Uneven Cutting or Poor Performance

In cases where the cutting is uneven or the performance declines, the first step is to examine the cutting blades for dullness or damage. If the blades appear worn, sharpening or replacing them may be necessary. Additionally, verify that the tires are inflated evenly and that the deck height is correctly adjusted. Keeping the undercarriage clean and free of debris is also crucial for maintaining consistent cutting quality.

Optimizing Performance for Longevity

Ensuring the efficient functioning of your equipment is crucial for its durability and extended lifespan. By adopting a proactive approach to maintenance and operation, users can significantly enhance the reliability and performance of their machines. This section outlines essential strategies to achieve optimal performance, ultimately leading to greater longevity.

Regular Maintenance Practices

Consistent upkeep is vital to prevent wear and tear. Regularly checking and replacing filters, oil, and belts can help maintain smooth operation. Keeping components clean and free from debris minimizes the risk of damage and enhances performance.

Proper Operating Techniques

Utilizing the correct methods during operation contributes greatly to the equipment’s longevity. Avoiding overloading and adhering to recommended settings not only prevents strain but also promotes efficiency. Taking the time to understand the equipment’s capabilities ensures optimal results without compromising its integrity.