When it comes to operating heavy machinery, having access to detailed guidance is essential for both safety and efficiency. This section offers a thorough overview that ensures users can maximize the potential of their equipment while minimizing risks. Whether you are a seasoned professional or a novice, understanding the operational principles is crucial for achieving optimal performance.

In the following paragraphs, we will delve into various aspects that pertain to the effective use and maintenance of this powerful machine. Key features, recommended practices, and troubleshooting tips will be highlighted to provide a well-rounded understanding. By familiarizing yourself with these elements, you will enhance your proficiency and confidence in handling the equipment.

Moreover, regular maintenance and adherence to guidelines not only prolong the lifespan of your machinery but also contribute to its reliability. The insights presented here aim to equip users with the necessary knowledge to tackle any challenges that may arise, ensuring that your experience is both productive and rewarding.

Key Features of Bobcat 763

This section highlights the essential attributes of a versatile compact loader that excels in various applications. Known for its robust performance and adaptability, this machinery is designed to handle diverse tasks efficiently, making it a favorite among professionals in construction, landscaping, and agriculture.

Performance and Power

The powerful engine delivers impressive torque and horsepower, allowing for efficient operation in tough conditions. The reliable hydraulic system enhances lifting capabilities, ensuring optimal performance for various attachments.

Compact Design

Its compact dimensions facilitate maneuverability in tight spaces, making it ideal for urban environments and confined job sites. The low profile ensures stability while working on uneven terrain, maximizing productivity and safety.

| Feature | Specification |

|---|---|

| Engine Type | Diesel |

| Operating Weight | Approx. 2,800 lbs |

| Rated Capacity | 1,200 lbs |

| Hydraulic Flow | 17.5 GPM |

| Overall Length | 118 inches |

Maintenance Tips for Optimal Performance

Ensuring the longevity and efficiency of your machinery requires regular upkeep and attention. Following essential maintenance practices can significantly enhance operational effectiveness and prevent unexpected breakdowns.

Regular Inspections: Conducting routine checks is vital for identifying wear and tear before they escalate into major issues. Pay attention to hydraulic fluids, belts, and filters, ensuring they are in optimal condition.

Proper Lubrication: Keeping all moving parts well-lubricated minimizes friction and reduces the risk of damage. Use the recommended lubricants and follow the specified intervals for application.

Cleaning and Debris Removal: Regularly clearing away dirt, dust, and debris from the machine prevents blockages and maintains airflow. This practice not only enhances performance but also extends the lifespan of critical components.

Adhering to Service Schedules: Following the manufacturer’s suggested service intervals ensures that all necessary maintenance tasks are performed timely. This practice aids in avoiding potential malfunctions and promotes optimal operation.

Staying Updated: Familiarize yourself with any updates or changes in maintenance recommendations. Being informed about the latest best practices can lead to improved performance and reliability.

Common Issues and Troubleshooting Steps

Every machine may encounter challenges during its operation, and understanding these potential problems is essential for effective maintenance. This section outlines typical concerns users may face along with practical steps for resolution, ensuring optimal functionality and longevity.

Engine Not Starting: If the engine fails to start, check the battery for charge and connections. A weak battery or loose terminals can often be the culprit. Ensure that the fuel tank is filled and that the fuel lines are not clogged.

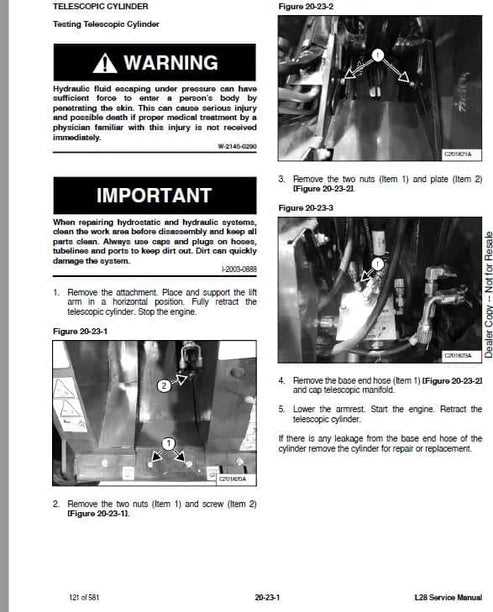

Hydraulic System Malfunction: Insufficient power or slow movement of hydraulic components can indicate low fluid levels or air in the system. Verify fluid levels and inspect for leaks in hoses and connections. Purging air from the system may be necessary for proper operation.

Strange Noises: Unusual sounds during operation can signify wear or damage. Inspect components for signs of excessive wear, particularly bearings and gears. Lubrication may be required to eliminate friction and prevent further damage.

Overheating: If the machine overheats, check the coolant levels and ensure that the radiator is clean. Clogged air filters can also impede airflow, leading to overheating. Regular maintenance of the cooling system is crucial.

Inconsistent Performance: If performance fluctuates, it may stem from fuel quality or clogged filters. Regularly replace filters and use high-quality fuel to maintain consistent operation. Additionally, consider checking ignition systems for faults.