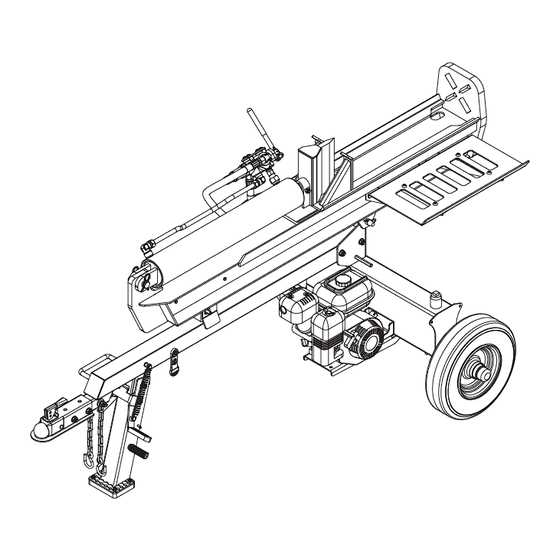

This section provides essential information regarding the operation and maintenance of a robust machine designed for efficiently handling wood materials. Understanding its features and functions will ensure optimal performance and longevity.

By familiarizing yourself with the equipment’s specifications and safety protocols, you can enhance your woodworking experience. It is crucial to follow the guidelines provided to maximize efficiency and prevent potential hazards during use.

In this guide, you will discover valuable tips for setup, operation, and troubleshooting. This knowledge will empower you to utilize the machine effectively, allowing for a smoother workflow and achieving desired results in your woodworking projects.

Guidelines for Safe Log Splitting

Ensuring safety during the process of cutting wood is crucial to prevent accidents and injuries. By adhering to established practices and guidelines, individuals can engage in this activity with greater confidence and security.

Preparation and Equipment

Before starting the task, it is essential to inspect all tools and machinery for proper functioning. Ensure that the equipment is suitable for the size and type of timber being processed. Additionally, wearing appropriate protective gear such as gloves, goggles, and sturdy footwear can significantly reduce the risk of injury.

Work Area Safety

Maintaining a clean and organized workspace is vital. Remove any obstacles that could cause tripping or hinder movement. Always position yourself in a way that allows for quick escape from potential hazards. By doing so, you enhance your ability to respond to unexpected situations effectively.

Maintaining the Efficiency of Your Log Splitter

Ensuring the optimal performance of your wood processing device requires regular upkeep and attention. By implementing simple maintenance practices, you can enhance its productivity and extend its lifespan. This section outlines key strategies to keep your equipment in peak condition.

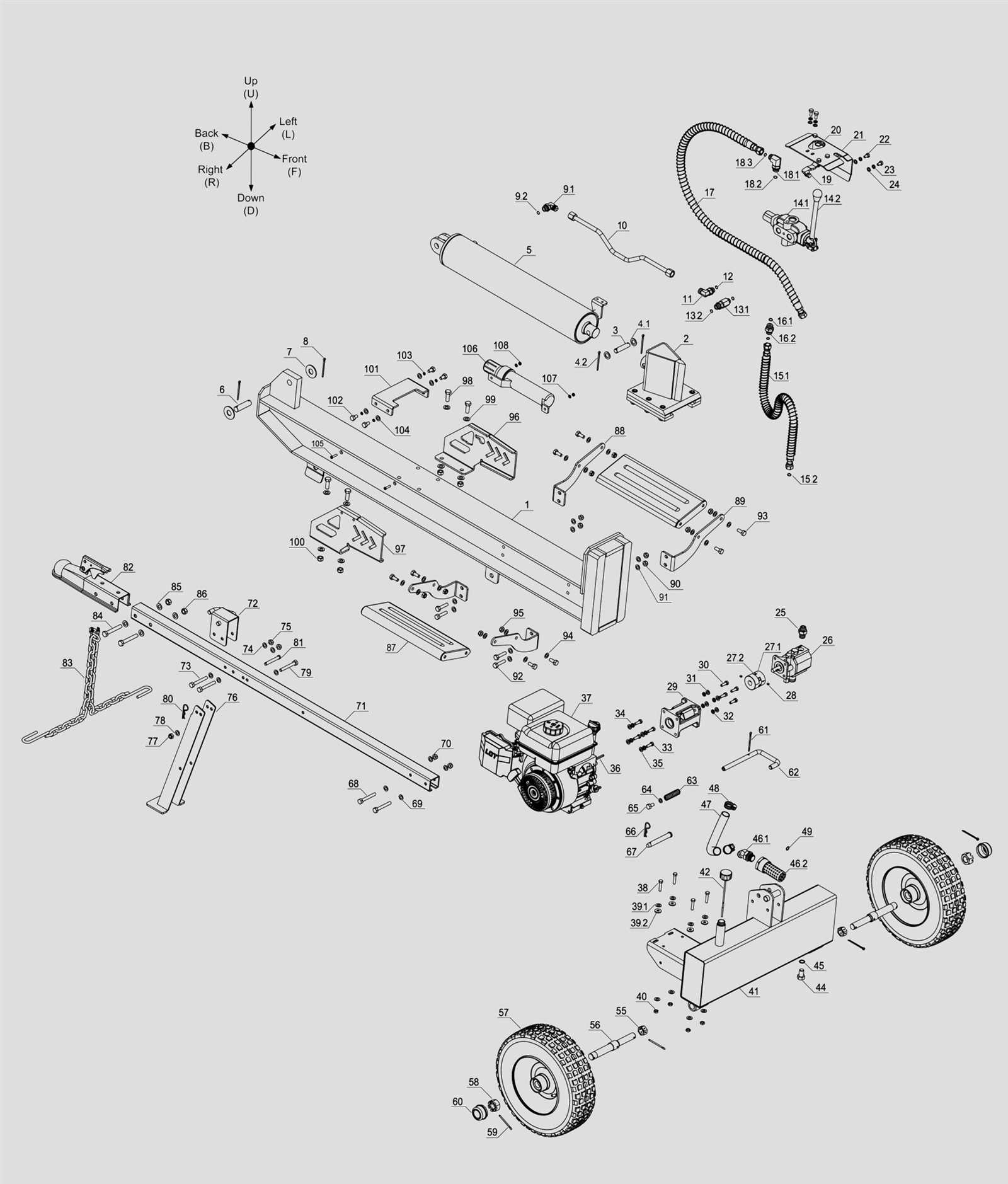

Regular Inspections: Conduct frequent checks of the machinery to identify any signs of wear or damage. Look for loose components, leaks, or unusual noises during operation. Addressing these issues promptly can prevent more significant problems in the future.

Lubrication: Proper lubrication is essential for reducing friction and wear on moving parts. Use the recommended lubricants and follow the manufacturer’s guidelines for application frequency. Regularly check the oil levels and top them up as needed to ensure smooth functioning.

Cleaning: Keep the exterior and interior of the machine clean from debris and dirt. Accumulated material can affect performance and lead to overheating. Use a soft brush or cloth to remove buildup, ensuring all vents and filters remain unobstructed.

Storage Practices: When not in use, store the equipment in a dry, sheltered environment to protect it from the elements. If possible, cover it with a tarp or protective covering to prevent dust and moisture accumulation.

Implementing these maintenance practices will significantly contribute to the reliability and effectiveness of your wood processing equipment, enabling you to tackle your tasks efficiently.

Regular Inspections and Troubleshooting Tips

Maintaining equipment in optimal condition is crucial for ensuring efficiency and safety during operation. Conducting routine assessments can help identify potential issues before they escalate, prolonging the lifespan of the machinery. This section outlines essential checks and solutions for common problems.

Key Inspection Areas

Focus on the following components during your evaluations:

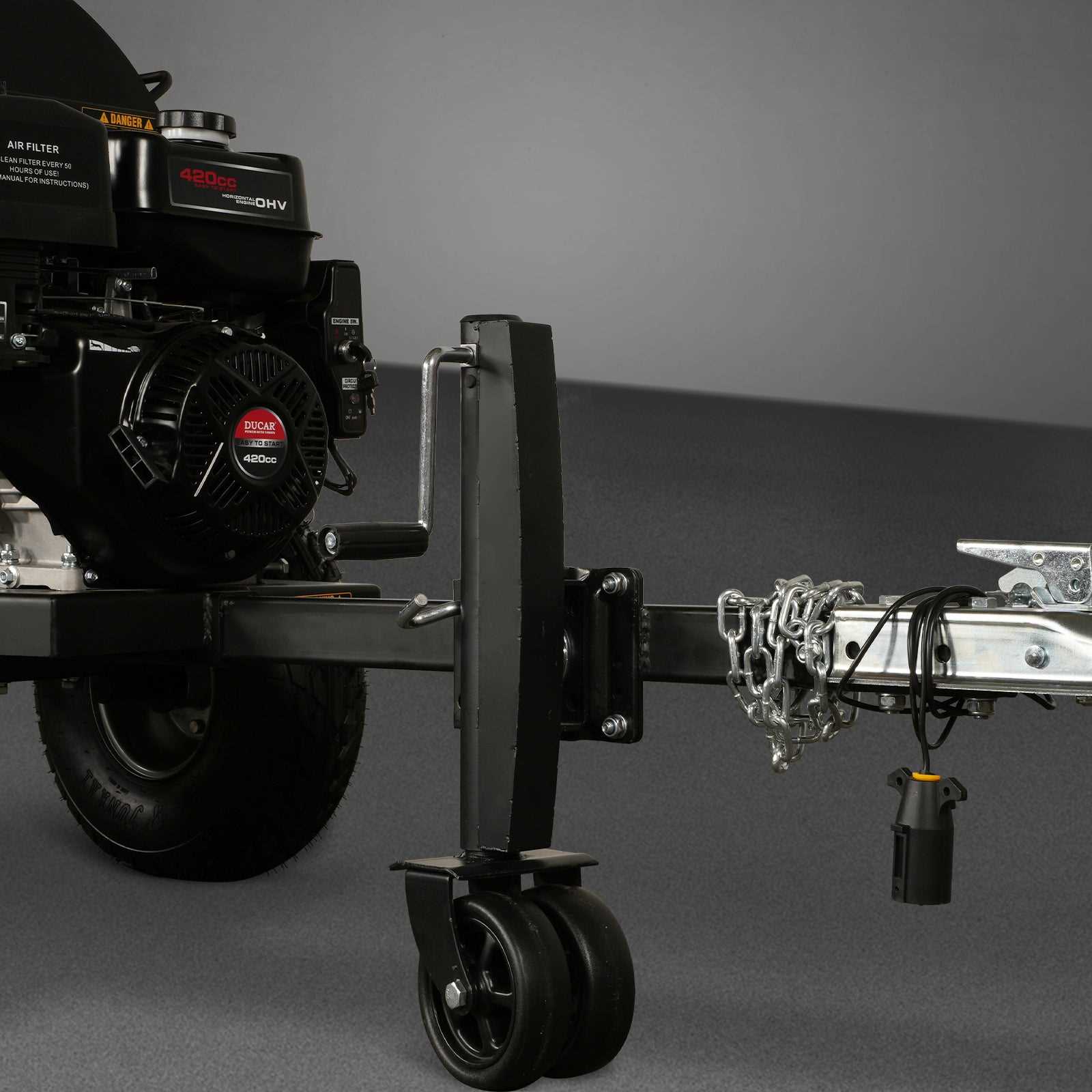

- Hydraulic system: Check for leaks and ensure fluid levels are adequate.

- Connections and fasteners: Inspect for any signs of wear or loosening.

- Electrical components: Verify that all wiring is intact and connections are secure.

- Physical condition: Look for any cracks or damage to the frame and other parts.

Troubleshooting Common Issues

If you encounter problems, consider these solutions:

- If the machine fails to operate, check the power supply and ensure all switches are engaged.

- For unusual noises, examine moving parts for obstructions or lack of lubrication.

- If performance decreases, inspect the hydraulic fluid for contamination or depletion.