In this section, we will delve into essential information that every user should be familiar with to maximize their experience and ensure the longevity of their equipment. Understanding the intricacies of your device is vital for both safety and performance. Proper handling and maintenance will not only enhance functionality but also contribute to a more enjoyable experience.

Preparation and Safety are fundamental aspects of using any advanced archery equipment. Familiarizing yourself with the various components and their specific functions will empower you to operate your device confidently. This knowledge is critical in preventing accidents and ensuring optimal usage.

Maintenance and Care play a crucial role in preserving the integrity of your gear. Regular checks and timely servicing can prevent wear and tear, extending the lifespan of your device. By adhering to recommended practices, users can maintain peak performance and reliability during use.

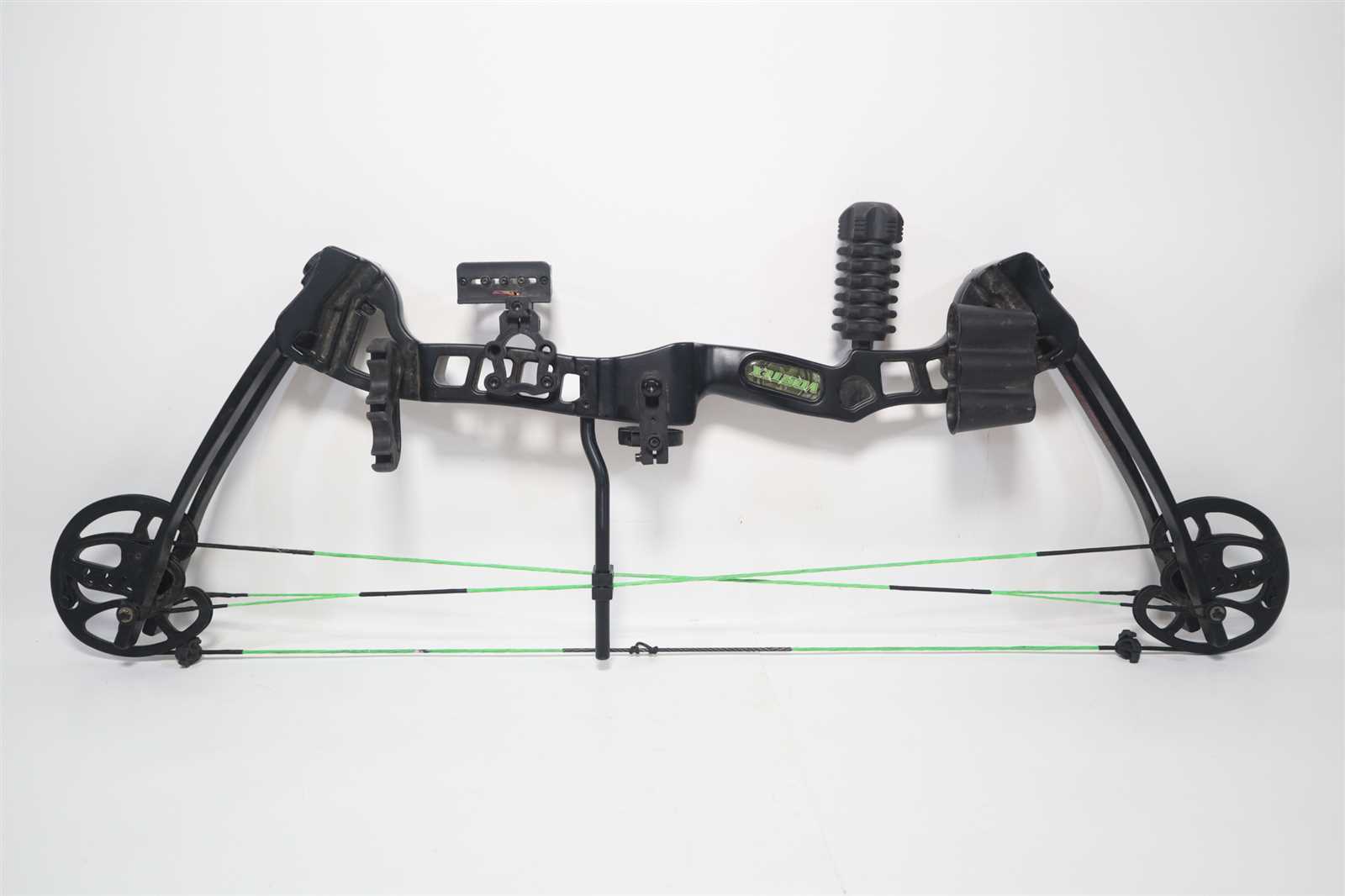

Understanding the Barnett Vortex Features

This section explores the distinctive characteristics of a popular archery product known for its performance and design. Understanding these elements can enhance the user experience and maximize effectiveness during use.

Key attributes of this archery device contribute to its reputation among enthusiasts. Below is a detailed overview of these features, highlighting their benefits:

| Feature | Description |

|---|---|

| Lightweight Construction | The innovative materials used ensure portability without sacrificing durability, making it easy to carry during extended sessions. |

| Adjustable Sight | The customizable sight system allows for precise targeting, accommodating various shooting preferences and conditions. |

| Ergonomic Grip | The thoughtfully designed handle provides comfort during use, reducing fatigue and improving control. |

| High-Speed Mechanism | Featuring advanced technology, this device delivers impressive speed and accuracy, elevating the performance for both beginners and seasoned users. |

| String and Cable System | The reliable string and cable arrangement enhances consistency and reduces maintenance, ensuring longevity and optimal performance. |

Maintenance Tips for Optimal Performance

Ensuring the longevity and efficiency of your equipment requires regular attention and care. By implementing a consistent maintenance routine, you can enhance the performance and reliability of your device, avoiding potential issues that may arise from neglect.

Here are some essential tips to help maintain your equipment effectively:

- Regular Inspections: Frequently check for any signs of wear and tear. Look for loose components, frayed cables, or any unusual noises during operation.

- Cleaning: Keep the device clean from dust and debris. Use a soft cloth and suitable cleaning products to wipe down surfaces and remove any buildup that could hinder performance.

- Lubrication: Apply appropriate lubricants to moving parts as per the manufacturer’s recommendations. This can help reduce friction and prevent premature wear.

- Calibration: Periodically calibrate your equipment to ensure accuracy and efficiency. Follow the guidelines provided for the best results.

- Storage: When not in use, store the device in a dry and safe environment. Avoid exposure to extreme temperatures or humidity, which can cause damage.

By following these maintenance tips, you can ensure that your device remains in top condition, providing optimal performance and extending its lifespan.

Troubleshooting Common Issues Effectively

When utilizing precision equipment, encountering challenges is not uncommon. This section aims to provide practical solutions for frequently reported problems, enabling users to address concerns swiftly and enhance their overall experience.

Identifying Performance Problems

Users may notice a decline in functionality, which could stem from various factors. Begin by examining the setup and ensuring that all components are correctly assembled. Additionally, check for any visible wear or damage that might impact performance. Regular maintenance is crucial; dirt or debris can hinder optimal operation.

Resolving Mechanical Issues

If mechanical complications arise, such as jamming or inconsistent operation, it’s essential to inspect moving parts. Lubrication may be required to ensure smooth movement. In cases where the issue persists, consider consulting technical specifications or seeking assistance from knowledgeable sources to determine further steps for resolution.