Understanding the proper use and care of machinery is essential for ensuring longevity and optimal performance. This guide offers insights on maintaining and operating equipment efficiently, helping users maximize functionality and minimize potential issues over time.

By following the instructions outlined here, users can gain a deeper comprehension of essential maintenance procedures and operational strategies. This section aims to provide clear information, enhancing the overall experience and safety for those working with the machinery.

Additionally, users will find helpful tips on troubleshooting common problems, ensuring that the equipment remains reliable and in top condition. Each aspect is discussed in detail to support efficient management and safe operation, making it a valuable resource for both beginners and experienced operators alike.

Maintenance Tips for Your Equipment

Regular upkeep is crucial to ensure that machinery remains in optimal working condition. Implementing a consistent routine helps extend the lifespan of various components, preventing unexpected issues and costly repairs. By staying proactive, operators can maintain peak performance and reliability, ensuring that the equipment is always ready for use.

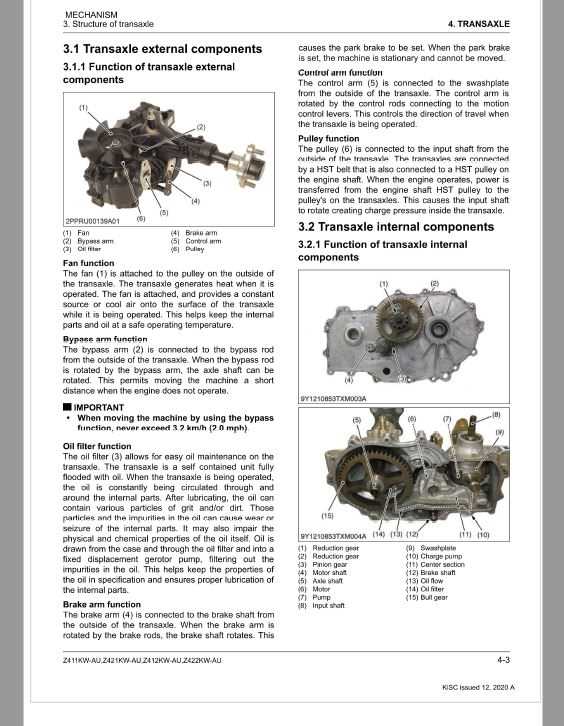

Lubrication and Fluid Levels

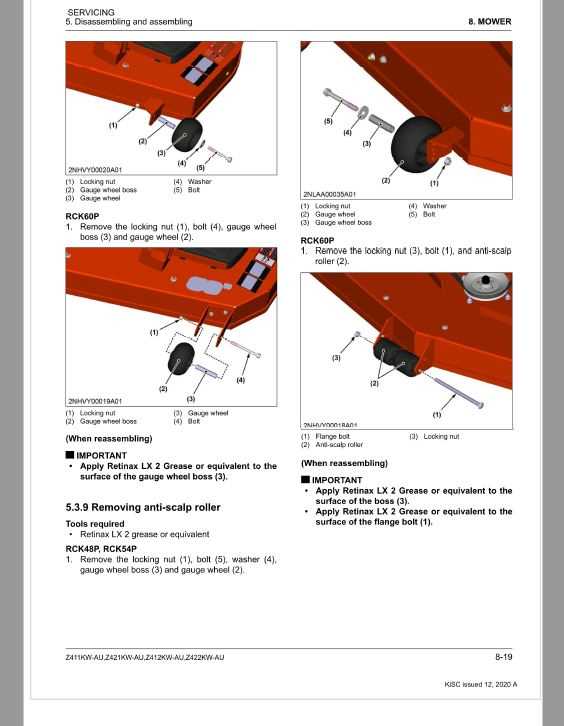

Proper lubrication reduces friction and wear on moving parts. It’s essential to regularly check and replenish fluid levels, such as engine oil and hydraulic fluids, to maintain smooth operations. Using high-quality lubricants and changing them according to recommended intervals will enhance the efficiency and longevity of the machinery.

Inspecting Wear and Tear

Frequent inspection of mechanical parts is vital to identify any signs of deterioration, such as worn belts, damaged hoses, or loose fasteners. Promptly replacing or repairing any defective elements minimizes the risk of further damage and ensures that the machine continues to operate safely and efficiently.

Understanding Safety Features and Controls

Ensuring safe operation of any equipment involves familiarizing oneself with various safety mechanisms and control elements. Recognizing how these features function not only prevents accidents but also contributes to a longer lifespan of the machinery. Proper use of these elements helps minimize risks and enhances overall efficiency.

Key Safety Mechanisms

Most modern machines are equipped with essential safety components designed to protect the operator. These may include seatbelt systems, roll-over protection structures, and automatic shutdown features that activate under unsafe conditions. Understanding these elements allows for confident handling and immediate response in emergency situations.

Control Panel Overview

The control panel typically houses several operational switches and indicators that assist in monitoring machine status. From throttle adjustments to parking brakes, each element serves a specific purpose and must be utilized correctly. Familiarity with these controls ensures smooth operation and reduces the likelihood of misuse or mechanical damage.

Proper Care for Long-Term Durability

Maintaining equipment effectively is crucial for ensuring its long-lasting performance and minimizing the risk of unexpected breakdowns. Regular attention and proper handling not only help in preserving its value but also enhance overall efficiency and reliability during use.

Routine Inspections: Regular checks of all mechanical components are essential to identify any wear or potential issues early on. Inspecting parts such as belts, filters, and fluids helps prevent small problems from escalating into major repairs.

Lubrication and Cleaning: Keeping all moving parts properly lubricated reduces friction and extends the lifespan of components. Periodic cleaning of the exterior and internal sections prevents the accumulation of debris and dirt, which can lead to corrosion or overheating.

Proper Storage: When not in use for extended periods, ensure the equipment is stored in a dry and protected environment. Covering it properly and disconnecting batteries can prevent unnecessary damage caused by exposure to harsh elements.

Implementing these steps consistently will contribute to the equipment’s durability, allowing it to perform reliably over time.