Maintaining a pristine lawn requires not only dedication but also the right equipment and knowledge. This guide aims to provide detailed insights and instructions on how to achieve the best results in your yard work. Whether you’re a seasoned gardener or just starting out, understanding the intricacies of your equipment can significantly enhance your lawn care routine.

In the following sections, you’ll find step-by-step guidelines, practical tips, and essential maintenance advice to keep your machinery running smoothly and efficiently. From setting up your equipment to troubleshooting common issues, this guide covers all the aspects you need to know to ensure optimal performance.

We will explore various features and functionalities that can help you get the most out of your lawn care tool. By following these recommendations, you can prolong the lifespan of your machine and ensure a consistently beautiful and healthy lawn. Dive into the sections ahead to become proficient in handling your lawn care tasks with ease and confidence.

Maintenance Guide

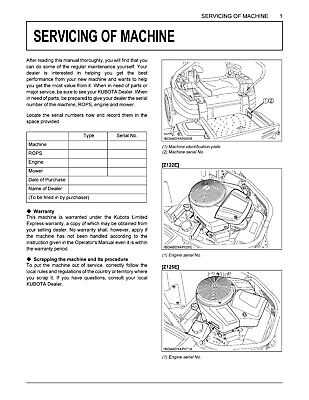

Regular upkeep is essential to ensure the longevity and optimal performance of your equipment. This guide provides detailed steps and tips for maintaining your machine efficiently and safely, covering all necessary tasks from routine inspections to more involved procedures.

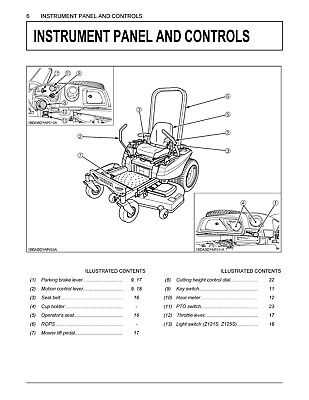

Routine Inspections: Regularly check key components such as the engine, blades, and belts. Look for signs of wear and tear, loose parts, and any unusual noises during operation. Ensuring these elements are in good condition will help prevent larger issues down the line.

Fluid Levels: It’s important to keep an eye on fluid levels, including oil, coolant, and hydraulic fluids. Make sure they are topped up and replaced according to the recommended schedule to avoid any potential damage to the engine and other critical parts.

Blade Maintenance: Sharpening and balancing the blades regularly will ensure a clean cut and reduce strain on the engine. Dull blades can tear the grass instead of cutting it, leading to an uneven finish and potential lawn damage.

Cleaning: After each use, remove debris and grass clippings from the underside of the deck, the engine compartment, and other accessible areas. This prevents buildup that can hinder performance and cause overheating.

Battery Care: Check the battery terminals for corrosion and ensure they are securely connected. Regularly

Regular Service Schedule

Maintaining a consistent maintenance routine for your equipment is essential to ensure its longevity and efficient performance. Regular service helps prevent unexpected breakdowns and costly repairs.

- Check and replace engine oil every 50 hours of operation.

- Inspect and clean the air filter every 100 hours, or more frequently in dusty conditions.

- Grease all fittings and pivot points every 25 hours to reduce wear.

- Examine the fuel filter and replace it every 200 hours to ensure a clean fuel supply.

- Inspect the spark plug every 100 hours and replace it if necessary for optimal engine performance.

- Check the tire pressure regularly to maintain proper traction and prevent uneven wear.

- Ensure the battery terminals are clean and connections are tight to avoid starting issues.

- Review the condition of belts and blades every 50 hours, and replace them if they show signs of wear or damage.

Adhering to this routine service schedule will help keep your machinery running smoothly and extend its operational life.

Essential Maintenance Tips

Regular maintenance of your equipment is crucial for ensuring optimal performance and longevity. By following a few key practices, you can keep your machine running smoothly and avoid costly repairs.

Check and Change Fluids

One of the most important aspects of maintenance is monitoring and replacing fluids. Ensure that oil, coolant, and hydraulic fluids are at the correct levels and change them as recommended. Using the right type and grade of fluids is essential for efficient operation.

Inspect and Clean Filters

Filters play a vital role in protecting the engine and other components from dirt and debris. Regularly inspect air, oil, and fuel filters and clean or replace them as needed. A clean filter can prevent engine damage and improve efficiency.

Regular Inspection: Periodically examine the overall condition of your equipment. Look for signs of wear, damage, or leaks. Address any issues promptly to prevent them from worsening.

Proper Lubrication: Ensure all moving parts are well-lubricated to reduce friction and wear. Check the manufacturer’s guidelines for the correct type of lubricant and apply it at the recommended intervals.

By adhering to these maintenance tips, you can extend the life of your equipment and maintain its performance. Consistent care and attention to detail are key to preventing breakdowns and ensuring reliability.

Common Troubleshooting Solutions

When operating any machinery, it’s inevitable to encounter occasional issues that may disrupt normal functioning. Understanding how to address these common problems efficiently can save time and prevent unnecessary downtime.

Engine Starting Issues

One frequent problem is difficulty in starting the engine. This can be due to a variety of factors such as fuel system problems, battery issues, or spark plug malfunctions.

- Check the fuel level and ensure the fuel valve is open.

- Inspect the battery for sufficient charge and clean connections.

- Examine the spark plug for wear and replace if necessary.

Uneven Cutting

Another common issue is uneven cutting, which can result from several causes related to the cutting deck and blades.

- Ensure the cutting deck is level and properly adjusted.

- Inspect the blades for sharpness and balance, and replace if they are damaged or dull.

- Check for obstructions beneath the deck that might hinder blade movement.

Hydraulic System Problems

Hydraulic system issues can lead to poor performance of various attachments and functions. Regular maintenance can help prevent these problems.

- Check hydraulic fluid levels and top up if necessary.

- Inspect hoses and connections for leaks or damage.

- Ensure the hydraulic filter is clean and replace if clogged.

Overheating

Overheating