The operation and maintenance of agricultural machinery play a crucial role in ensuring efficiency and longevity. Understanding the intricacies of your equipment can significantly enhance its performance and reliability. This section aims to provide comprehensive insights into the key features, recommended practices, and essential care techniques for your machine.

Farmers and operators alike benefit from a well-structured guide that outlines operational procedures and maintenance schedules. By adhering to best practices, users can prevent common issues and ensure that their machinery operates at peak efficiency. The following information is designed to empower you with the knowledge necessary to maximize the potential of your equipment.

From troubleshooting tips to routine care suggestions, this resource serves as an invaluable companion in your agricultural journey. Investing time in understanding your equipment will not only enhance its lifespan but also contribute to a more productive farming experience. Stay informed, stay efficient!

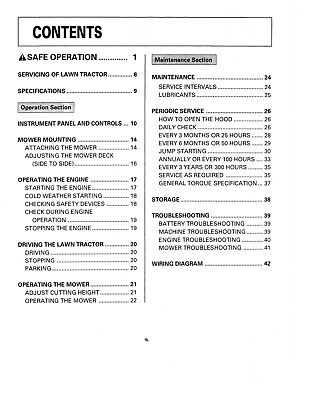

Maintenance Tips

Regular upkeep is essential for optimal performance and longevity of your machine. Following a consistent maintenance routine helps prevent issues and ensures that the equipment operates smoothly, enhancing productivity and reliability. This section offers key suggestions for keeping your machinery in peak condition.

Routine Inspection

Conducting periodic checks is vital. Focus on examining the oil levels, air filters, and tire pressures. Regular inspections help identify potential problems early, allowing for timely interventions and repairs. Ensure that all connections and fittings are secure, as loose components can lead to more significant issues.

Cleaning and Lubrication

Keeping the equipment clean is crucial for its operation. Regularly remove dirt and debris from surfaces, especially around the engine and cooling systems. Additionally, apply appropriate lubricants to moving parts as recommended. This not only reduces friction but also prolongs the lifespan of vital components.

Following these tips can greatly enhance the functionality and durability of your machinery, making sure it remains a reliable asset for your tasks.

Understanding the Operator Controls

The effective operation of any machinery relies heavily on the user’s familiarity with its control systems. This section will explore the essential elements that empower operators to navigate and utilize the equipment efficiently. Each control serves a specific purpose and understanding their functions is crucial for optimal performance.

Here are the main components of the operator controls:

- Throttle Control: Adjusts the engine speed, allowing for variations in power output depending on the task at hand.

- Steering Wheel: Provides directional control, enabling the operator to maneuver the machine accurately.

- Brake Pedals: Ensures safe stopping and control of the speed, crucial for managing the equipment effectively.

- Gear Selector: Enables the operator to change gears, which impacts the speed and torque of the machine.

- Hydraulic Controls: Operate attachments or implements, allowing for various tasks such as lifting or tilting.

Familiarity with these controls not only enhances operational efficiency but also contributes to safety during use. Operators are encouraged to practice and become comfortable with these elements to ensure a smooth working experience.

Common Troubleshooting Techniques

When facing issues with your equipment, it’s essential to utilize effective strategies to identify and resolve problems efficiently. Understanding common troubleshooting techniques can significantly streamline the process and enhance performance.

- Visual Inspection: Begin with a thorough examination of the machine. Look for any obvious signs of wear, damage, or loose connections that may contribute to the malfunction.

- Check Fluid Levels: Ensure that all essential fluids, such as oil, coolant, and fuel, are at appropriate levels. Low fluids can lead to overheating or other operational failures.

- Examine Filters: Regularly inspect and clean or replace air and fuel filters to maintain optimal airflow and fuel delivery, which are crucial for proper functioning.

Following these preliminary steps can help pinpoint issues quickly. If problems persist, consider the following additional methods:

- Consult Diagnostic Codes: Many machines are equipped with diagnostic systems that can provide error codes to indicate specific problems. Refer to the relevant documentation to interpret these codes.

- Test Electrical Components: Use a multimeter to check the integrity of electrical components such as batteries, switches, and connectors. Faulty wiring can often cause operational issues.

- Seek Professional Help: If all else fails, don’t hesitate to reach out to a qualified technician who can provide expert assistance and in-depth analysis of the situation.