Understanding the operation and maintenance of your agricultural machinery is essential for optimal performance and longevity. This section aims to provide comprehensive insights into the features and functionalities of your tractor, ensuring you can make the most of its capabilities.

Equipping yourself with knowledge about the essential components, operating techniques, and maintenance schedules can significantly enhance your productivity. Emphasizing safety and efficiency will empower you to tackle various tasks effectively, whether in the field or during routine checks.

By familiarizing yourself with these aspects, you will not only protect your investment but also improve your operational efficiency. Proper care and informed usage will lead to a smoother experience, allowing you to focus on the agricultural challenges ahead.

Understanding the Kubota M7060 Features

This section provides an overview of the key attributes and functionalities of the agricultural vehicle, highlighting its capabilities and design elements that enhance performance and user experience.

The machine is equipped with several advanced features that make it suitable for various tasks:

- Powerful Engine: Designed for optimal performance, ensuring efficient operation across different terrains.

- Ergonomic Controls: User-friendly layout that allows operators to manage functions easily and intuitively.

- Versatile Attachments: Compatible with a range of implements, making it adaptable for multiple applications.

- Durable Construction: Built to withstand harsh conditions while maintaining reliability and longevity.

- Advanced Hydraulics: Facilitates smooth operation of attachments and enhances productivity.

These features combine to create a machine that not only meets but exceeds expectations for agricultural tasks, offering efficiency, comfort, and adaptability.

Maintenance Tips for Optimal Performance

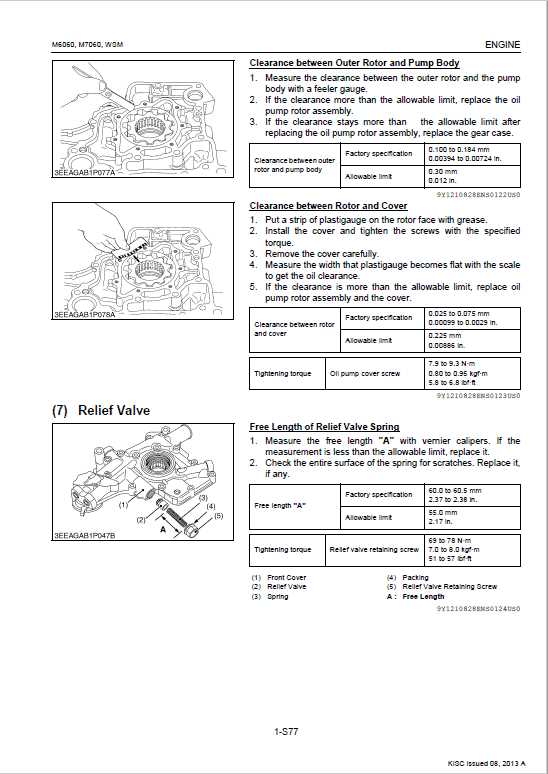

Regular upkeep is essential to ensure that machinery operates efficiently and lasts longer. Proper maintenance not only enhances performance but also prevents unexpected breakdowns, allowing for smooth operations throughout the year.

Routine Checks

- Inspect fluid levels, including engine oil, coolant, and hydraulic fluids, regularly.

- Examine belts and hoses for signs of wear or damage.

- Check tire pressure and tread condition to ensure stability and safety.

Cleaning and Lubrication

- Clean air filters and replace them as needed to maintain airflow and efficiency.

- Lubricate moving parts according to the manufacturer’s specifications to reduce friction.

- Wash the exterior to remove dirt and debris, preventing corrosion and wear.

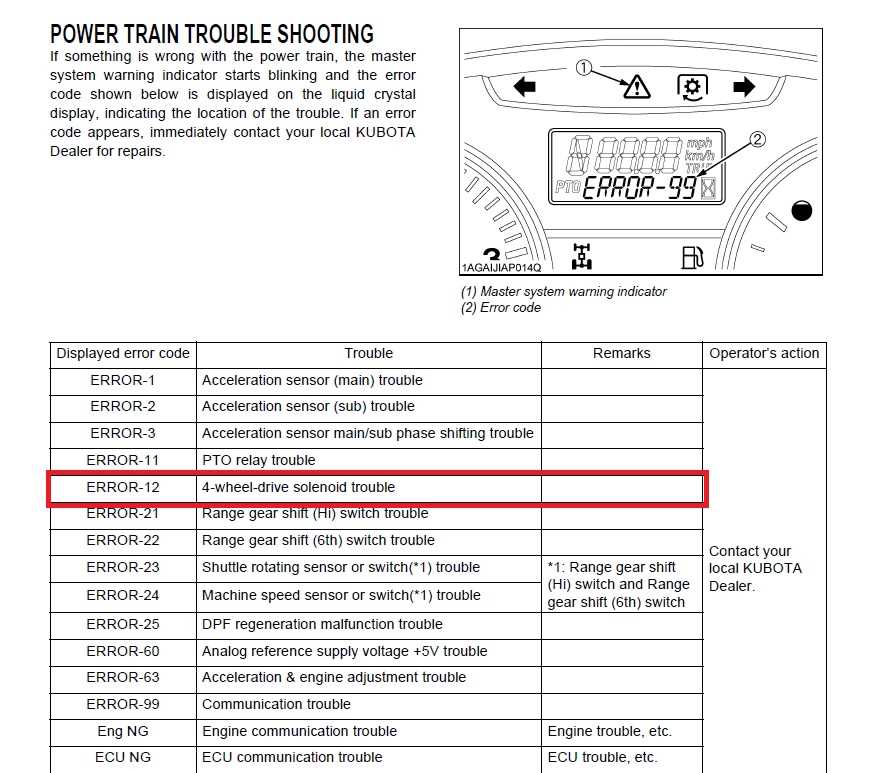

Common Troubleshooting Techniques

Addressing issues with equipment requires a systematic approach to identify and resolve problems effectively. Implementing basic troubleshooting techniques can significantly enhance performance and reliability.

Start by following these general steps:

- Observe Symptoms: Carefully note any unusual sounds, vibrations, or warning lights that may indicate a malfunction.

- Check the Manual: Consult the documentation for specific guidance related to common issues and maintenance tips.

- Inspect Components: Examine all critical parts, including fluid levels, filters, and belts for wear and tear.

In addition to these steps, consider the following common techniques:

- Resetting Systems: Sometimes, simply restarting the equipment can resolve electronic glitches.

- Performing a Visual Inspection: Look for any visible signs of damage or leaks that could affect functionality.

- Testing Electrical Connections: Ensure all wiring is secure and free from corrosion or damage.

Utilizing these troubleshooting techniques can help diagnose problems efficiently and maintain optimal operation.