Owning and operating machinery comes with the responsibility of understanding its features, maintenance, and operational guidelines. This section aims to provide valuable insights into the complexities of managing your vehicle efficiently. By familiarizing yourself with crucial information, you can ensure optimal performance and longevity.

Every piece of machinery has unique specifications that must be adhered to for safe and effective usage. This resource is designed to assist users in navigating the essential protocols and procedures necessary for daily operations. Whether you are a seasoned operator or a newcomer, having access to comprehensive information enhances your experience and contributes to successful handling.

In this guide, you will find detailed explanations, troubleshooting tips, and maintenance schedules that are vital for keeping your machinery in peak condition. By following the outlined instructions, you can prevent potential issues and make informed decisions regarding repairs and upkeep. Embrace the opportunity to enhance your knowledge and become proficient in managing your equipment.

Understanding the Features of the Machine

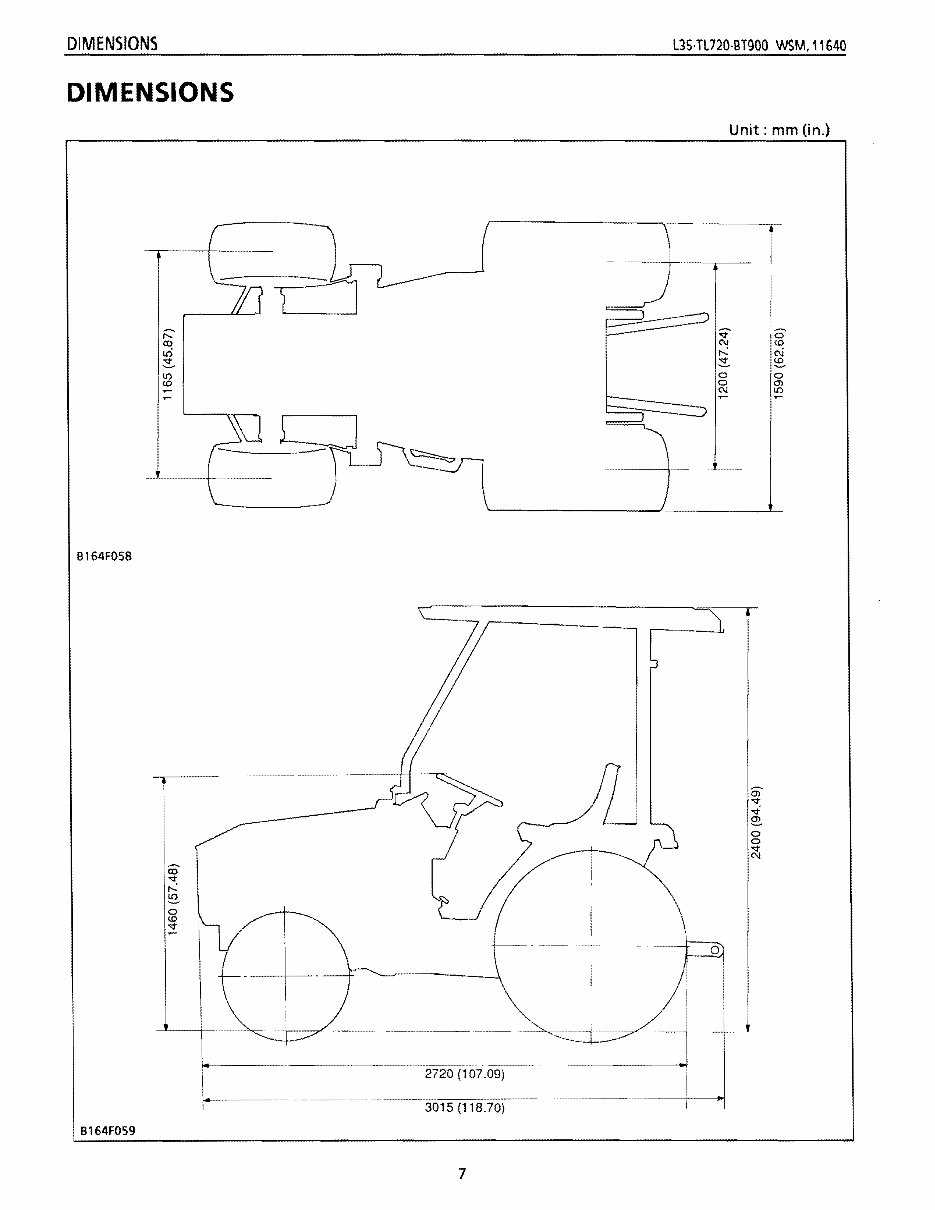

This section provides an overview of the distinctive characteristics and functionalities that set this compact equipment apart from its peers. By exploring the various components and capabilities, users can gain insights into how to maximize efficiency and performance during operation.

Key Components

The machinery is equipped with a robust engine designed to deliver exceptional power while maintaining fuel efficiency. Additionally, the ergonomic controls allow for easy maneuverability, making it user-friendly for both seasoned operators and novices alike. The inclusion of advanced hydraulic systems enhances its versatility, enabling it to handle various attachments and tasks seamlessly.

Operational Benefits

One of the standout advantages of this equipment is its ability to perform in diverse environments. Its compact size allows for agility in tight spaces, while the durable construction ensures reliability under demanding conditions. Furthermore, the intuitive interface simplifies operation, allowing users to focus on their tasks rather than struggling with complex controls.

Maintenance Tips for Your Kubota L35

Regular upkeep is essential for ensuring the longevity and optimal performance of your machinery. By adhering to a systematic maintenance routine, you can prevent potential issues and enhance the efficiency of your equipment.

1. Routine Inspections: Conduct frequent checks of fluid levels, filters, and belts. This proactive approach allows you to identify wear and tear before it leads to significant problems.

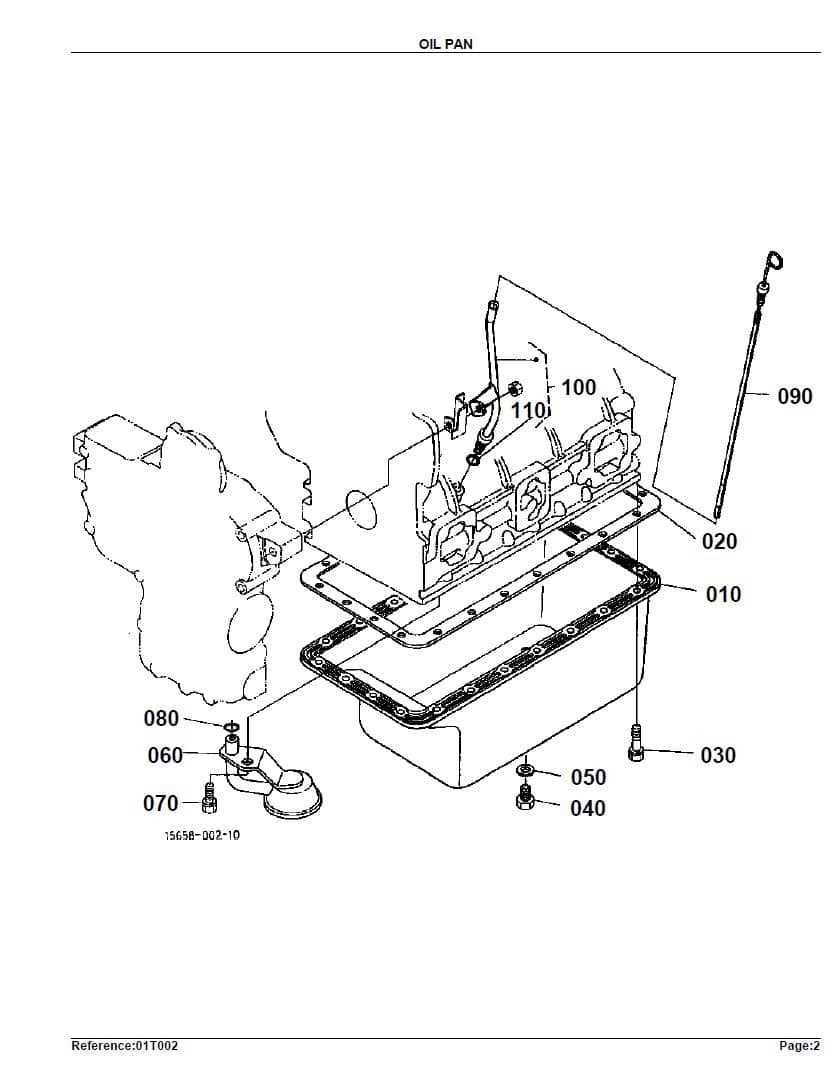

2. Fluid Changes: Timely replacement of engine oil, hydraulic fluid, and coolant is vital. Clean fluids ensure smooth operation and prevent overheating or mechanical failure.

3. Air Filter Maintenance: Keep the air filter clean and replace it as necessary to guarantee optimal airflow to the engine, enhancing performance and fuel efficiency.

4. Tire Care: Regularly inspect tire pressure and tread depth. Properly inflated tires improve traction and fuel efficiency, while also ensuring safety during operation.

5. Battery Checks: Inspect the battery terminals for corrosion and ensure secure connections. A well-maintained battery contributes to reliable starting and overall efficiency.

6. Lubrication: Regularly lubricate moving parts to reduce friction and wear. This simple step can significantly extend the life of your machinery.

By following these maintenance recommendations, you can maximize the performance and lifespan of your equipment, ensuring it remains a reliable asset for your tasks.

Common Issues and Troubleshooting Guide

This section addresses frequent problems encountered by users of compact utility machines and offers practical solutions for effective maintenance. Understanding these common challenges can help in prolonging the lifespan of the equipment and ensuring optimal performance.

Starting Difficulties: One of the most prevalent issues is trouble with starting the engine. This may be due to a weak battery, poor fuel quality, or malfunctioning ignition components. Regularly check the battery condition and ensure that fuel is clean and fresh.

Hydraulic System Failures: Hydraulic problems can manifest as erratic movements or lack of power. It is essential to inspect hydraulic fluid levels and check for leaks in hoses and connections. Replacing filters regularly can also prevent such issues.

Overheating: Machines may overheat during operation, which can be caused by a blocked radiator or low coolant levels. Cleaning the radiator and ensuring adequate coolant levels are crucial steps to avoid overheating.

Unusual Noises: Strange sounds during operation often indicate mechanical issues. It is advisable to investigate any abnormal noises promptly, as they may signal wear in components or loose fittings. Regular maintenance checks can help identify and resolve these issues before they escalate.

By recognizing these common issues and implementing proactive measures, users can effectively troubleshoot problems and maintain their machinery in peak condition.