In the world of agricultural machinery, understanding the nuances of your equipment is essential for maximizing efficiency and longevity. This section serves as a comprehensive resource designed to equip users with the necessary knowledge to operate their compact tractors effectively. Whether you’re a seasoned farmer or a first-time user, familiarizing yourself with the features and functions of your machine can significantly enhance your productivity.

From maintenance routines to troubleshooting common issues, this guide provides insights that ensure optimal performance. Emphasis is placed on the importance of adhering to recommended practices to safeguard your investment. By grasping the intricacies of your tractor, you not only extend its lifespan but also improve its operational capabilities, making it an indispensable tool in your daily tasks.

Moreover, gaining an understanding of the safety measures and operational guidelines is paramount. This section aims to empower users with the confidence to handle their machinery adeptly, fostering a proactive approach to both routine and unexpected challenges. With the right information at your fingertips, you can navigate the intricacies of your tractor with ease.

Essential Features of the Kubota B7200

This compact utility vehicle is designed to meet the diverse needs of landowners, farmers, and landscapers. Its combination of efficiency, durability, and ease of use makes it a popular choice for various agricultural and gardening tasks.

Powerful Engine and Performance

The robust powertrain of this machine ensures reliable operation under different conditions. Key characteristics include:

- High horsepower output for demanding tasks.

- Fuel-efficient operation, reducing running costs.

- Responsive transmission for smooth maneuverability.

Versatile Attachments and Accessories

This vehicle is compatible with a wide range of implements, enhancing its versatility. Users can equip it with:

- Front loaders for material handling.

- Backhoes for digging and trenching.

- Mowers for effective grass cutting.

- Snow blowers for winter maintenance.

These features collectively make it a reliable tool for various outdoor tasks, ensuring that users can tackle their projects with ease and efficiency.

Maintenance Guidelines for Optimal Performance

Regular upkeep is essential for ensuring the longevity and efficiency of your agricultural equipment. Implementing a systematic maintenance routine can significantly enhance performance and reduce the risk of unexpected breakdowns. This section outlines key practices that can help maintain optimal functionality throughout the operational life of your machinery.

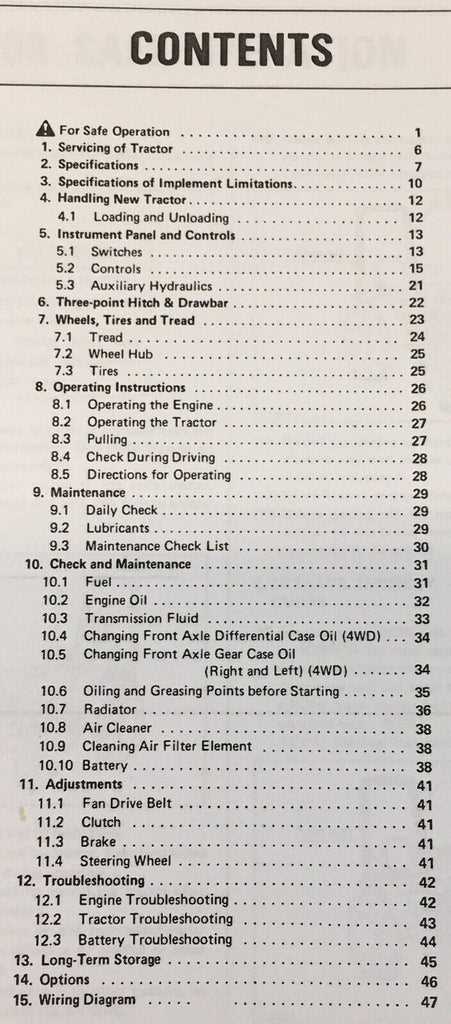

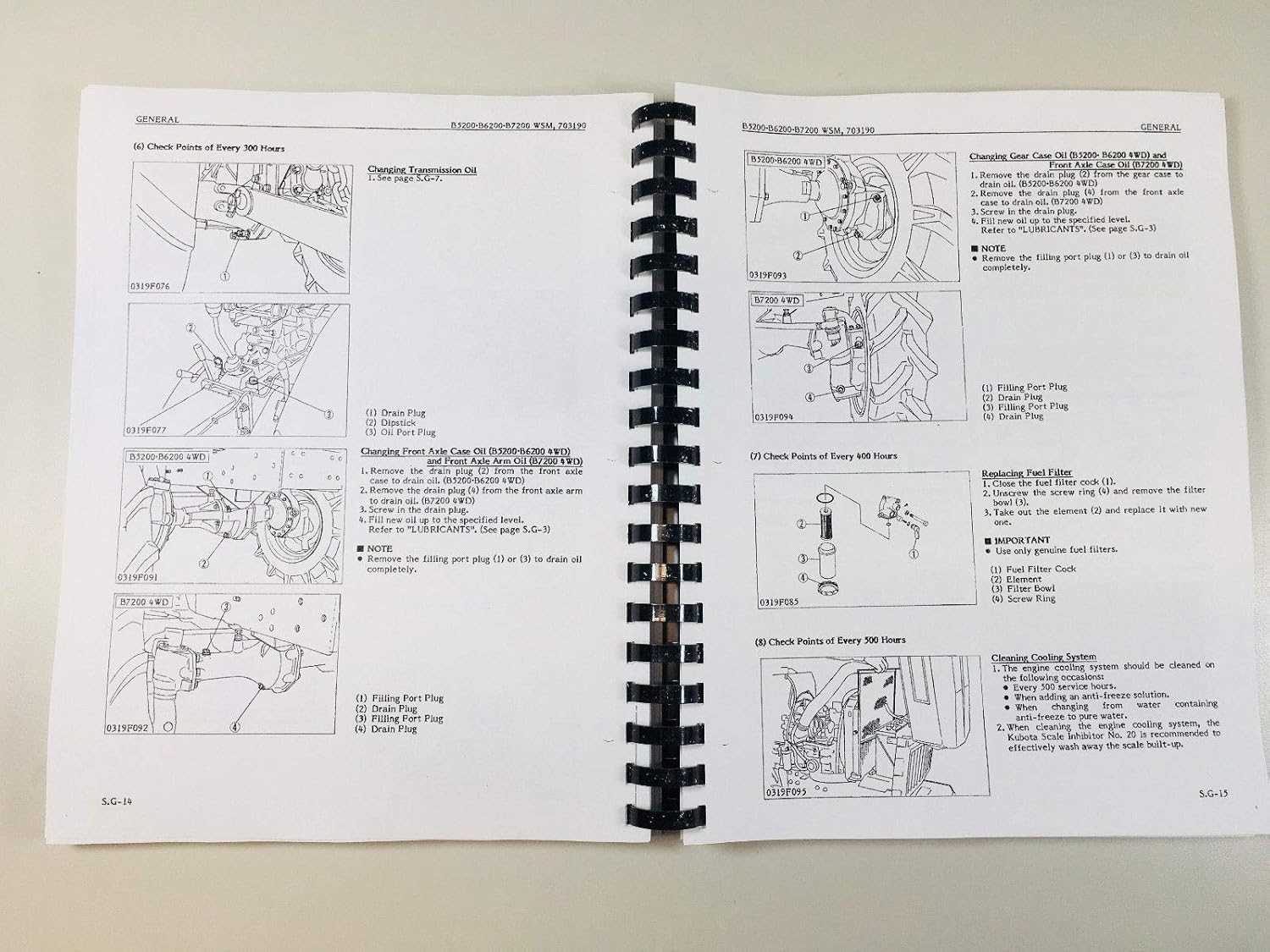

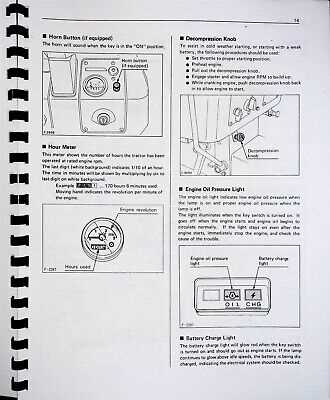

First and foremost, it’s crucial to adhere to the recommended service intervals. Regular checks of essential components, such as the engine oil, fuel filters, and hydraulic fluids, are vital to keep the system running smoothly. Replacing worn parts promptly will prevent further damage and ensure reliable operation.

Additionally, cleaning the air filters and checking the cooling system should be part of your regular maintenance schedule. Accumulated dirt can hinder airflow and cooling efficiency, leading to overheating and reduced power output. Keeping these components clean will not only improve performance but also extend the life of the equipment.

Finally, ensure that all fasteners and fittings are secure. Regularly inspect belts and hoses for signs of wear or damage, and replace them as necessary. A proactive approach to maintenance will help in identifying potential issues before they escalate, resulting in smoother operations and increased productivity.

Troubleshooting Common Issues in Operation

When operating machinery, encountering difficulties is a common experience for users. Identifying and resolving these issues promptly is essential for maintaining efficiency and prolonging the equipment’s lifespan. This section will cover prevalent problems faced during operation and provide effective solutions.

- Engine Won’t Start

- Check the fuel level and ensure that it is sufficient.

- Inspect the battery connections for corrosion or loose terminals.

- Examine the ignition system for any faults or damaged components.

- Overheating

- Verify that the coolant levels are adequate.

- Inspect the radiator for blockages or leaks.

- Ensure that the cooling fan is operational.

- Poor Performance

- Examine the air filter for dirt and replace if necessary.

- Check the fuel filter for clogs.

- Ensure that the throttle is functioning correctly.

- Unusual Noises

- Listen for any grinding or rattling sounds that may indicate worn parts.

- Inspect the belts and chains for signs of wear.

- Examine the engine mounts for looseness or damage.

By following these guidelines and conducting regular checks, operators can minimize disruptions and ensure smooth functionality.