This section is designed to provide essential information for individuals utilizing compact machinery in various tasks. By understanding the operational features and maintenance procedures, users can ensure efficient performance and longevity of their equipment.

Within these guidelines, you will discover vital insights into troubleshooting common challenges, recommended servicing schedules, and key specifications that enhance user experience. Knowledge of these aspects is crucial for maximizing productivity and minimizing downtime during operations.

Additionally, practical tips for safe handling and proper usage will be presented, ensuring that all activities conducted with the machinery are carried out efficiently and securely. This comprehensive resource aims to equip you with the necessary tools to maintain optimal functionality throughout the life of your equipment.

Understanding Your Kubota B2100

The compact tractor you own is designed for versatility and efficiency in various agricultural and landscaping tasks. It combines power and maneuverability, making it an excellent choice for both small-scale farming and residential use. Familiarizing yourself with its features and capabilities will enhance your overall experience and ensure optimal performance.

Key Features: This machine is equipped with a reliable engine that provides sufficient power for demanding tasks while maintaining fuel efficiency. The hydraulic system is robust, enabling the use of various implements and attachments, which significantly increases its functionality.

Maintenance Considerations: Regular upkeep is crucial for sustaining the performance of your equipment. Routine checks of fluids, filters, and belts will prolong its lifespan and enhance reliability. Understanding the maintenance schedule will help you keep your tractor in peak condition.

Moreover, familiarizing yourself with the operational controls and safety features is essential for effective usage. Knowing how to adjust settings and utilize different functions can maximize productivity and minimize the risk of accidents.

In summary, mastering the capabilities and maintenance requirements of your compact tractor will not only improve its efficiency but also contribute to a safer and more enjoyable operating experience.

Essential Features and Specifications

This section highlights the key characteristics and technical details that define the compact tractor’s capabilities and performance. Understanding these features is crucial for optimizing the use of the equipment in various agricultural and landscaping tasks.

Key Features

- Powerful engine providing reliable performance for diverse applications.

- Compact size facilitating maneuverability in tight spaces.

- Hydrostatic transmission for smooth operation and ease of control.

- Four-wheel drive enhancing traction on varied terrains.

- Versatile attachment compatibility allowing for multiple functionalities.

Specifications Overview

- Engine Type: Liquid-cooled, four-stroke diesel engine.

- Horsepower: Approximately 21 HP, delivering ample power for demanding tasks.

- Transmission: Hydrostatic, providing seamless speed adjustments.

- Weight: Around 1,600 lbs, ensuring stability during operation.

- Lift Capacity: Capable of lifting significant loads for various implements.

Maintenance Guidelines for Longevity

Proper upkeep of your equipment is essential for ensuring its durability and performance over time. Regular maintenance tasks not only enhance functionality but also extend the lifespan of your machinery. By adhering to a consistent schedule of checks and services, you can prevent potential issues and ensure that your machine operates at its best.

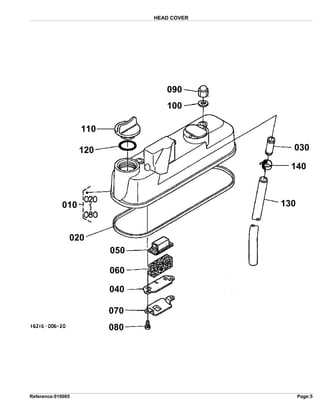

Regular Inspections

Conducting frequent assessments of various components is crucial for identifying wear and tear. These inspections should include examining fluid levels, belts, and other key parts that contribute to overall performance. Early detection of any irregularities can help avoid more extensive repairs down the line.

Fluid Changes

Changing fluids at recommended intervals is vital for optimal operation. Clean fluids promote better lubrication and cooling, which are essential for preventing overheating and component damage. Always refer to the guidelines for specific intervals and types of fluids required.

| Maintenance Task | Frequency |

|---|---|

| Engine Oil Change | Every 50 hours |

| Fuel Filter Replacement | Every 200 hours |

| Air Filter Inspection | Every 100 hours |

| Hydraulic Fluid Check | Monthly |

Troubleshooting Common Operating Issues

This section aims to provide guidance for identifying and resolving frequent problems that users may encounter while operating their compact utility vehicles. Understanding these challenges can enhance the overall efficiency and longevity of the equipment.

Common Symptoms and Solutions

When operating the machine, you might experience various issues. Below is a table outlining typical symptoms along with potential solutions:

| Symptoms | Possible Solutions |

|---|---|

| Engine won’t start | Check the battery charge and connections. Ensure fuel is available and the ignition switch is functioning. |

| Unusual noises while operating | Inspect for loose components or foreign objects. Lubricate moving parts as needed. |

| Poor performance or lack of power | Examine the air filter for clogs. Verify fuel quality and replace if necessary. |

| Overheating | Check coolant levels and radiator for blockages. Ensure the cooling fan is operating correctly. |

Regular Maintenance Tips

Preventive care can mitigate many common issues. Regularly scheduled maintenance tasks include checking fluid levels, replacing filters, and inspecting belts and hoses. Keeping a close eye on these aspects will help ensure smooth operation.