This section serves as a vital resource for users looking to enhance their understanding of a specific power tool. It covers essential aspects, from initial setup to ongoing maintenance, ensuring optimal performance and longevity of the device.

Whether you’re a novice or a seasoned professional, having a reliable reference can significantly improve your experience. This guide offers practical insights and detailed instructions to help users navigate various functionalities and troubleshooting tips effectively.

With a focus on user empowerment, this compilation aims to equip individuals with the knowledge needed to maximize the potential of their equipment. Engaging with the information provided here will foster confidence in operating and maintaining your tool over time.

Maintenance Tips for Efficient Operation

Regular upkeep is essential for ensuring optimal performance and longevity of your equipment. Implementing effective maintenance practices not only enhances efficiency but also minimizes the risk of unexpected breakdowns. This section provides essential tips to keep your device running smoothly.

Firstly, always ensure that the air filter is clean and free from debris. A clogged filter can restrict airflow, leading to decreased efficiency. Additionally, inspect the spark plug regularly; a worn or dirty spark plug can hinder engine performance. Replacing it as needed can make a significant difference.

Oil levels should be monitored consistently. Use the recommended oil type and change it as specified in the guidelines to ensure proper lubrication of the engine. Furthermore, checking the fuel system for leaks or contaminants is crucial to prevent operational issues.

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Clean Air Filter | Every 25 hours of operation | Replace if damaged |

| Inspect Spark Plug | Every 50 hours of operation | Replace if worn |

| Change Oil | Every 50 hours of operation | Use specified oil type |

| Check Fuel System | Before each use | Look for leaks or debris |

Proper Chain and Bar Care

Maintaining the chain and guide bar of your cutting tool is essential for optimal performance and longevity. Regular attention to these components ensures efficient operation, reduces wear, and enhances safety during use. Understanding how to care for these parts will help prevent common issues and improve cutting efficiency.

One of the primary aspects of care involves lubrication. A well-lubricated chain minimizes friction and heat, which can lead to damage. Additionally, periodic cleaning is vital to remove debris and resin build-up, which can hinder performance. Inspecting for wear or damage should also be a routine practice to avoid unexpected failures.

| Maintenance Task | Frequency | Description |

|---|---|---|

| Chain Lubrication | Before each use | Apply appropriate lubricant to ensure smooth operation and prevent overheating. |

| Cleaning | After each use | Remove debris and resin from the chain and bar to maintain efficiency. |

| Inspection | Weekly | Check for wear, damage, and tension to ensure safe operation. |

| Tension Adjustment | As needed | Ensure the chain is properly tensioned to avoid derailment during use. |

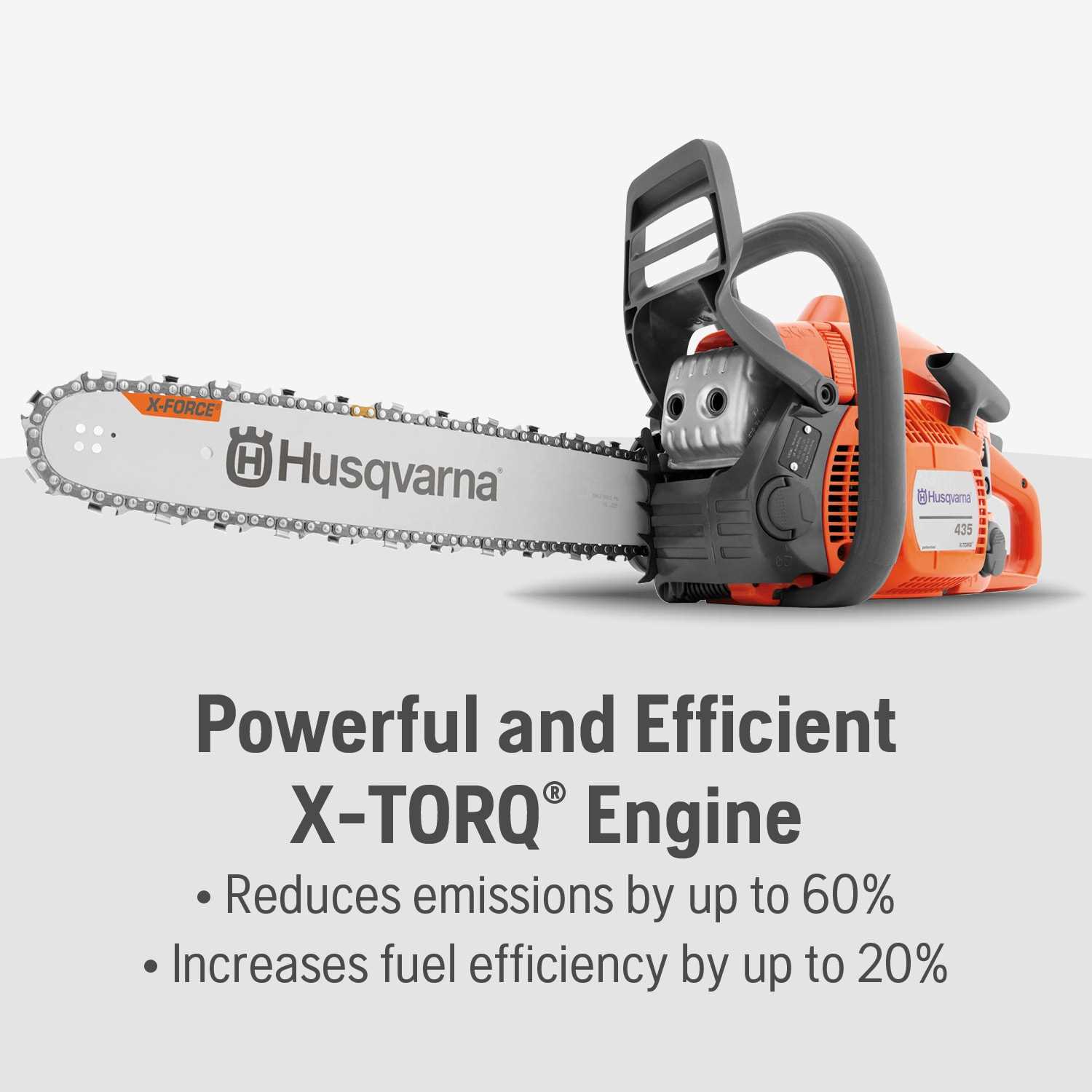

Fuel Efficiency and Optimal Performance

Achieving maximum efficiency and performance from your equipment is essential for both cost savings and longevity. Understanding the factors that contribute to fuel consumption and operational effectiveness can help you maintain a well-functioning machine. This section outlines key considerations for enhancing energy efficiency while ensuring top-notch performance during use.

Regular maintenance is a cornerstone of optimizing fuel efficiency. Keeping the engine components in good condition can significantly reduce the amount of fuel consumed. Additionally, using high-quality fuel and lubricants tailored for your specific machinery can lead to better combustion and performance outcomes.

| Tip | Description |

|---|---|

| Routine Maintenance | Perform regular checks and servicing to ensure all parts function smoothly. |

| Quality Fuels | Utilize recommended fuels to promote efficient engine operation. |

| Proper Techniques | Employ recommended techniques during operation to enhance fuel utilization. |

| Weight Management | Avoid unnecessary loads to minimize strain on the engine. |

By implementing these practices, you can enhance fuel efficiency and ensure optimal performance for your equipment. The goal is to create a harmonious balance between energy use and output, allowing for longer operation times and reduced costs.

Safety Precautions for Extended Use

When engaging in prolonged operation of power equipment, it is essential to adhere to specific safety measures to ensure personal well-being and optimal performance. Awareness of potential hazards and proper handling techniques can significantly reduce the risk of accidents and injuries.

Proper Attire: Always wear suitable clothing, including sturdy footwear and protective gear such as gloves, goggles, and hearing protection. This attire helps shield against debris and minimizes exposure to harmful noise levels.

Regular Breaks: Taking frequent breaks during extended usage is crucial. This practice not only prevents fatigue but also allows for a thorough inspection of the equipment, ensuring that it remains in optimal working condition.

Environmental Awareness: Be mindful of your surroundings. Clear the area of obstacles, and be cautious of changes in terrain or weather conditions that could affect operation. Maintaining a safe distance from bystanders is also important to avoid any potential injuries.

Correct Operation Techniques: Familiarize yourself with the equipment’s functionalities and follow the recommended operational guidelines. Improper use can lead to equipment malfunction or personal injury, so understanding how to handle the machinery correctly is vital.

Maintenance and Care: Regular maintenance checks are necessary to keep the equipment in good working order. Ensure that all components are functioning properly and replace any damaged parts immediately to prevent accidents during operation.

By following these precautions, users can enhance their safety and efficiency while operating power tools for extended periods, ensuring a more enjoyable and productive experience.