Understanding the key functions and features of modern machines can significantly enhance their performance and longevity. A well-organized approach to operation and upkeep ensures smooth functionality, helping to prevent common issues and extend the lifespan of the equipment.

In this guide, you will find essential information on how to properly handle and care for your equipment. By following these recommendations, you can make sure the machinery continues to serve you effectively, while reducing the need for unexpected repairs. Regular attention to detail in terms of cleaning and maintenance plays a crucial role in keeping everything running smoothly.

By familiarizing yourself with the general practices outlined here, you can optimize the performance of your equipment and ensure safe and reliable use over time. These tips will provide a strong foundation for getting the most out of your machine while avoiding unnecessary complications.

Overview of the Craftsman R110 Features

This section highlights the essential attributes and functionalities of the equipment, emphasizing its user-friendly design and versatile applications. Understanding these features can help users maximize the potential of their device for various tasks.

Key Features

- Powerful Engine: Designed for efficient performance in a range of conditions.

- Durable Construction: Built with high-quality materials for longevity and resilience.

- Ergonomic Design: Provides comfort during use, reducing fatigue over extended periods.

- Adjustable Settings: Offers customizable options for different tasks and preferences.

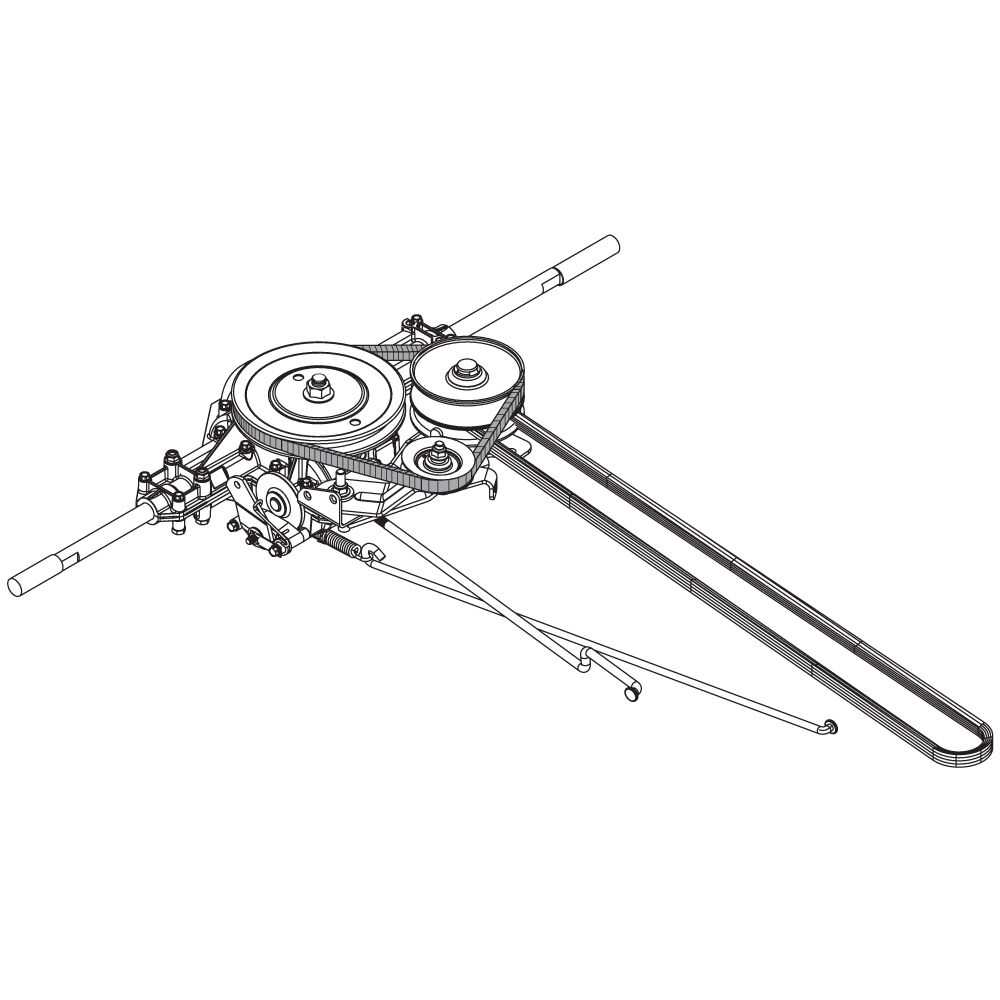

- Easy Maintenance: Simplified access to components for straightforward upkeep.

Additional Functionalities

- Safety Features: Equipped with various safety mechanisms to protect the user during operation.

- Storage Solutions: Includes compartments for convenient organization of tools and accessories.

- Versatile Attachments: Compatible with a range of add-ons for enhanced functionality.

Basic Setup and Maintenance Tips

Establishing a reliable foundation for your equipment is essential for optimal performance and longevity. Proper setup and regular maintenance not only enhance functionality but also ensure safety during use. This section provides essential guidelines to help you get started and maintain your device effectively.

Initial Configuration

Begin by selecting a suitable location that is well-ventilated and free from obstructions. Ensure that the surface is level to prevent instability during operation. Follow the provided instructions to assemble components accurately, making sure all connections are secure. After assembly, conduct a thorough inspection to confirm that all parts are in proper condition and functioning as intended.

Routine Care

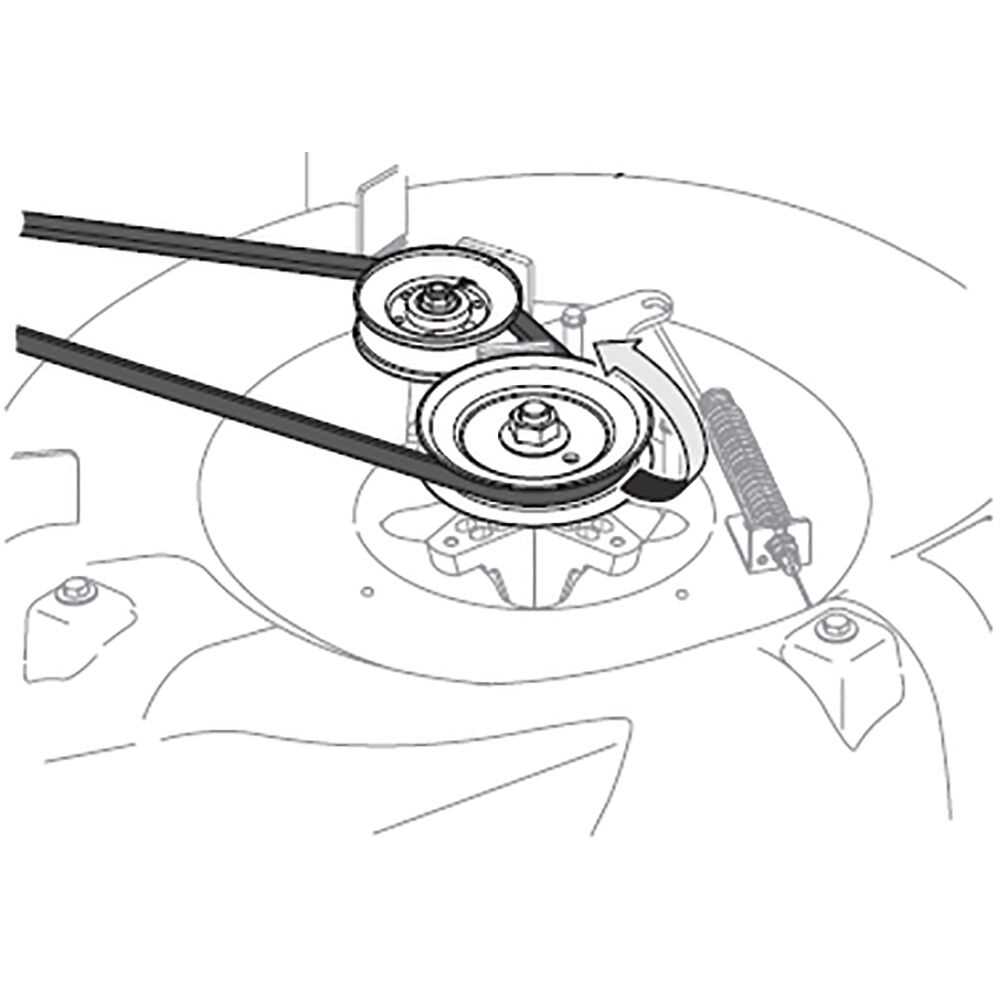

Regular upkeep is crucial for maintaining performance. Schedule periodic checks to clean and lubricate moving parts, which can help prevent wear and tear. Always follow the manufacturer’s recommendations regarding maintenance intervals. Additionally, keeping the workspace tidy and free from debris can further enhance safety and efficiency while using the equipment.

Common Issues and How to Resolve Them

When operating a power tool, users may encounter various challenges that can affect performance and efficiency. Understanding these common problems and their solutions can greatly enhance the user experience and prolong the tool’s lifespan. Below are some frequently faced issues along with effective strategies to address them.

Tool Not Starting

If the equipment fails to power on, check the power source first. Ensure that the connection is secure and that the outlet is functioning properly. It may also be helpful to inspect the power cord for any visible damage. If the tool still does not operate, the internal components may need to be evaluated by a professional.

Overheating

Overheating is often a sign of excessive strain on the tool or inadequate ventilation. To resolve this, allow the device to cool down during use and ensure that air vents are not blocked. Regular maintenance, including cleaning and lubrication, can also prevent overheating issues. If overheating persists, consider consulting a technician for further inspection.