In the realm of maintenance and operation, a comprehensive guide serves as an essential resource for users seeking to enhance their understanding of their equipment. This section is designed to provide valuable insights, ensuring that you can navigate the features and functionalities with confidence and ease. A well-structured guide facilitates a smoother user experience, empowering individuals to maximize the potential of their tools.

Whether you are a novice or a seasoned user, familiarizing yourself with the intricacies of your equipment is crucial. Detailed instructions and helpful tips can significantly impact performance and longevity. Emphasizing safety protocols and optimal usage techniques, this section aims to equip you with the knowledge necessary for effective operation and maintenance.

By following the outlined procedures and recommendations, users can foster a deeper connection with their tools. This not only enhances productivity but also promotes a sense of ownership and responsibility towards the care of the equipment. Engaging with this information is the first step towards ensuring that your experience is both enjoyable and efficient.

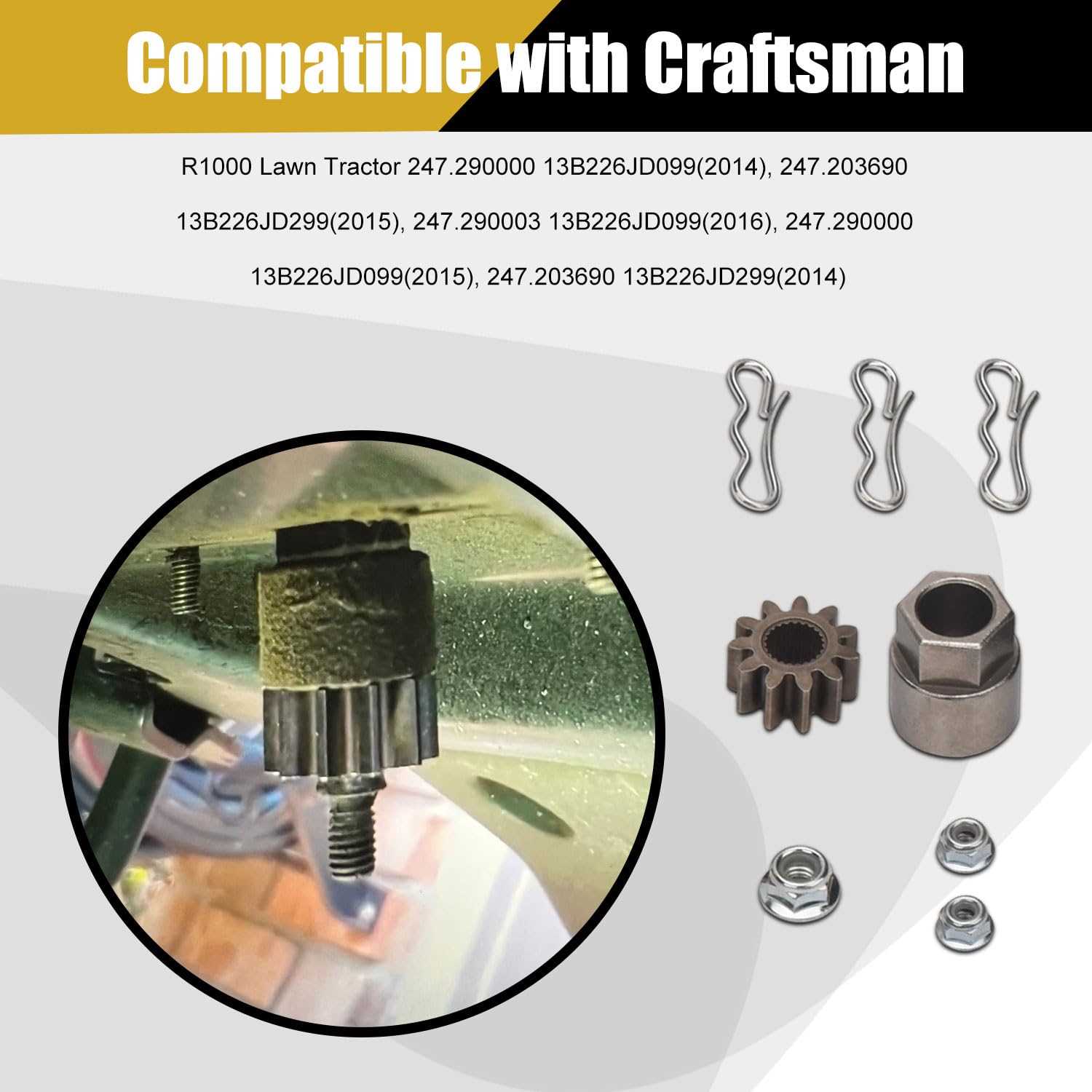

Understanding Your Craftsman R1000

Familiarizing yourself with your new tool is essential for maximizing its potential and ensuring efficient operation. This section will guide you through the key features and functionalities that enhance your experience. Grasping the capabilities and settings of your device can significantly improve your performance and outcomes in various tasks.

Key Features

Each device comes equipped with a variety of functionalities designed to simplify tasks. Below are some of the main features to explore:

| Feature | Description |

|---|---|

| Power Settings | Adjustable levels for optimal performance based on the task at hand. |

| Safety Mechanisms | Built-in systems to prevent accidents and ensure user protection during operation. |

| Ergonomic Design | Thoughtfully crafted for comfort and ease of use, reducing fatigue during prolonged use. |

Operating Principles

Understanding the operating principles is crucial for effective utilization. Proper handling and awareness of the device’s mechanics will lead to better results and prolonged lifespan.

Maintenance Tips for Optimal Performance

To ensure that your equipment operates smoothly and efficiently, regular upkeep is essential. Adhering to a systematic maintenance routine can significantly enhance longevity and functionality. This section highlights key practices that will keep your device in top shape, ensuring it performs at its best.

Regular Inspection and Cleaning

Routine checks are crucial for identifying potential issues before they escalate. Inspect all components for signs of wear or damage. Cleaning is equally important; accumulated dirt and debris can hinder performance. Utilize appropriate tools to remove dust and grime, focusing on areas prone to buildup.

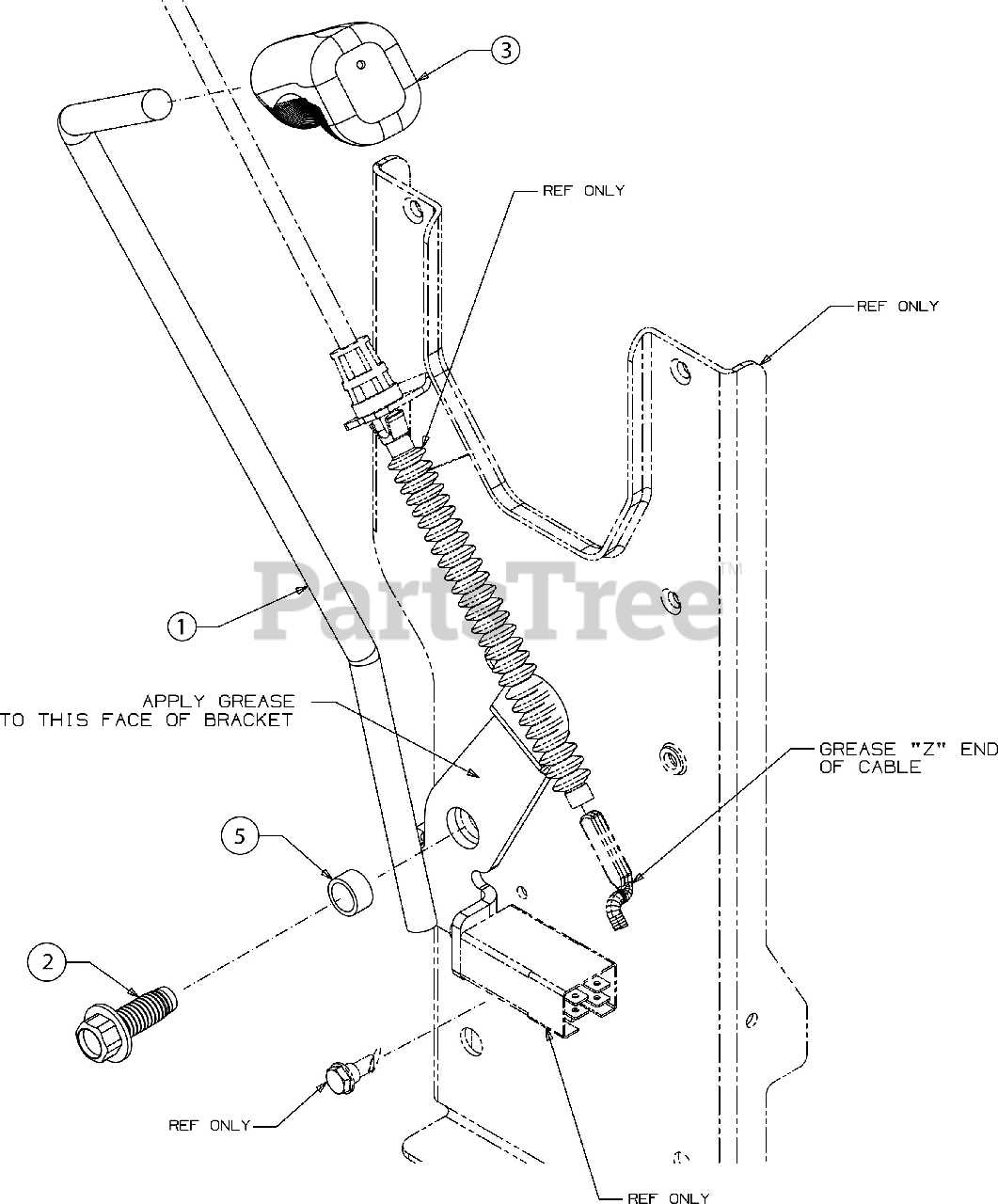

Lubrication and Calibration

Ensuring that moving parts are properly lubricated can minimize friction and prevent premature wear. Follow manufacturer guidelines for the type of lubricant to use and frequency of application. Additionally, calibration of settings should be performed periodically to maintain accuracy and efficiency, guaranteeing optimal operation.

Safety Guidelines for Safe Operation

Ensuring the safety of both the operator and the equipment is paramount when engaging with any machinery. Adhering to established protocols not only minimizes the risk of accidents but also enhances the overall efficiency of operations. It is essential to familiarize oneself with the recommended safety practices and maintain a conscientious attitude throughout usage.

Personal Protective Equipment

Before initiating any task, always don the appropriate personal protective equipment (PPE). This includes safety goggles to shield the eyes from debris, ear protection to guard against high noise levels, and gloves to protect the hands from potential injuries. Wearing suitable attire, such as fitted clothing and closed-toe shoes, is also crucial in preventing entanglement or accidents.

Operational Precautions

Prior to commencing operations, inspect the machinery for any signs of damage or wear. Ensure all safety features are functional and that the work area is free from clutter. Maintain a clear understanding of the operational procedures and follow them diligently. If any irregularities occur during use, cease operations immediately and conduct a thorough evaluation to identify the issue.