When it comes to maximizing the efficiency and longevity of your agricultural equipment, having access to detailed guidance is essential. This section provides invaluable insights into the various functions and features of your machinery, ensuring you can operate it with confidence and ease.

Understanding the operational aspects and maintenance requirements can significantly enhance your experience. You’ll find crucial information that aids in troubleshooting common issues, performing routine upkeep, and optimizing performance. Whether you’re a seasoned operator or new to this type of equipment, this resource aims to equip you with the knowledge necessary for effective management.

Delving into the intricacies of your equipment, you’ll discover practical tips and best practices that can make a substantial difference in your daily tasks. From detailed operational instructions to maintenance schedules, this guide is designed to empower you to get the most out of your investment.

Understanding the John Deere 4630 Features

The subject of this section revolves around the essential characteristics and functionalities of a renowned agricultural machine, focusing on how these elements enhance performance and efficiency in various farming tasks. With a blend of innovative technology and user-friendly design, this equipment is tailored to meet the demands of modern agriculture.

This model boasts a powerful engine that provides the necessary torque for demanding operations, ensuring reliable performance whether in the field or during transport. Its advanced hydraulic system facilitates seamless attachment changes, making it versatile for numerous tasks such as plowing, tilling, and hauling.

Moreover, the thoughtfully designed operator’s station emphasizes comfort and accessibility, allowing users to maintain productivity over long hours. Features such as ergonomic controls and adjustable seating contribute to a more pleasant working environment, reducing fatigue and enhancing overall efficiency.

In addition, the durable construction and high-quality materials used in its manufacturing guarantee longevity and resilience in challenging conditions. This robust design minimizes maintenance needs, ensuring that the machine remains operational with minimal downtime.

Ultimately, the integration of these features makes this agricultural powerhouse an invaluable asset for those seeking to optimize their farming practices while ensuring reliability and ease of use.

Maintenance Tips for Your 4630 Tractor

Ensuring the longevity and optimal performance of your agricultural machine requires regular upkeep and attention to detail. By following a structured maintenance routine, you can prevent common issues and enhance the efficiency of your equipment.

Start by routinely checking fluid levels, including engine oil, coolant, and hydraulic fluids. Keeping these at recommended levels is crucial for smooth operation and can prevent overheating or mechanical failures.

Next, pay attention to the air filter. A clean air filter promotes better engine performance by ensuring adequate airflow. Regularly inspect and replace it as necessary to maintain optimal efficiency.

Tires are another vital aspect of maintenance. Regularly check tire pressure and tread depth to ensure proper traction and fuel efficiency. Rotate tires periodically to promote even wear and extend their lifespan.

Finally, consult your specific guidelines for seasonal tasks, such as winterizing your machine. Proper storage and preparation for varying weather conditions will significantly enhance your equipment’s durability and reliability.

Common Issues and Troubleshooting Guide

This section provides a comprehensive overview of frequent challenges faced by operators of agricultural machinery and offers practical solutions. Understanding these common problems can enhance the efficiency and longevity of the equipment, ensuring optimal performance during critical tasks.

Engine Performance Issues

Operators may encounter symptoms such as difficulty starting, uneven idling, or reduced power output. These issues can often be traced back to fuel supply problems, air filter blockages, or electrical system malfunctions. Regular maintenance, including fuel system cleaning and air filter replacement, can mitigate these problems effectively.

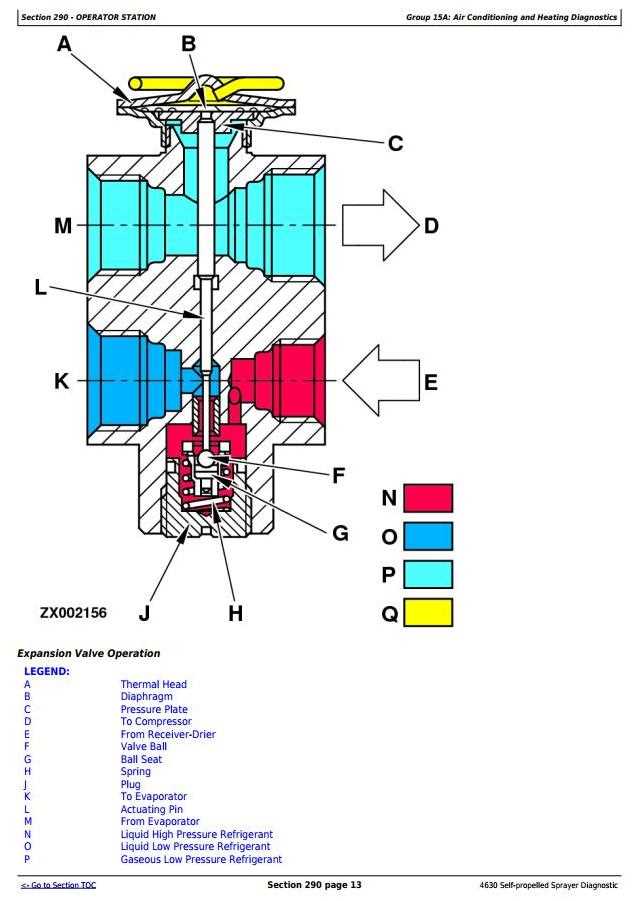

Hydraulic System Failures

Hydraulic complications, including leaks or inconsistent pressure, can significantly impact the functionality of attachments and overall performance. To address these issues, inspect hydraulic hoses for wear and tear, ensure proper fluid levels, and check for any obstructions in the system. Routine checks and timely repairs can prevent major breakdowns.