The reliable and efficient operation of a small marine engine is essential for a smooth and enjoyable experience on the water. Whether you’re using it for fishing, leisurely trips, or more demanding tasks, understanding how to properly maintain and operate your engine ensures both its longevity and your safety. This guide provides the necessary information for anyone seeking to master the care and use of their aquatic power source.

Throughout this detailed guide, you’ll find step-by-step instructions on maintaining optimal performance, troubleshooting common issues, and maximizing the efficiency of your motor. Proper upkeep and regular checks are critical, helping you avoid potential problems and ensuring that the engine runs smoothly every time it’s needed. We’ll explore essential maintenance tips and best practices to keep your equipment in top shape.

Additionally, this guide will offer insight into fuel management, seasonal storage, and safe handling practices. By following the outlined recommendations, you’ll gain confidence in managing your equipment, ensuring that every trip on the water is both safe and enjoyable.

Essential Maintenance for Mercury 8hp 4 Stroke Engines

Regular upkeep is vital to ensure the longevity and performance of your marine engine. By following a consistent care routine, you can prevent potential problems and keep the motor running efficiently, even under demanding conditions. Proper attention to maintenance tasks is a key factor in prolonging the operational life of the engine.

Routine Inspections

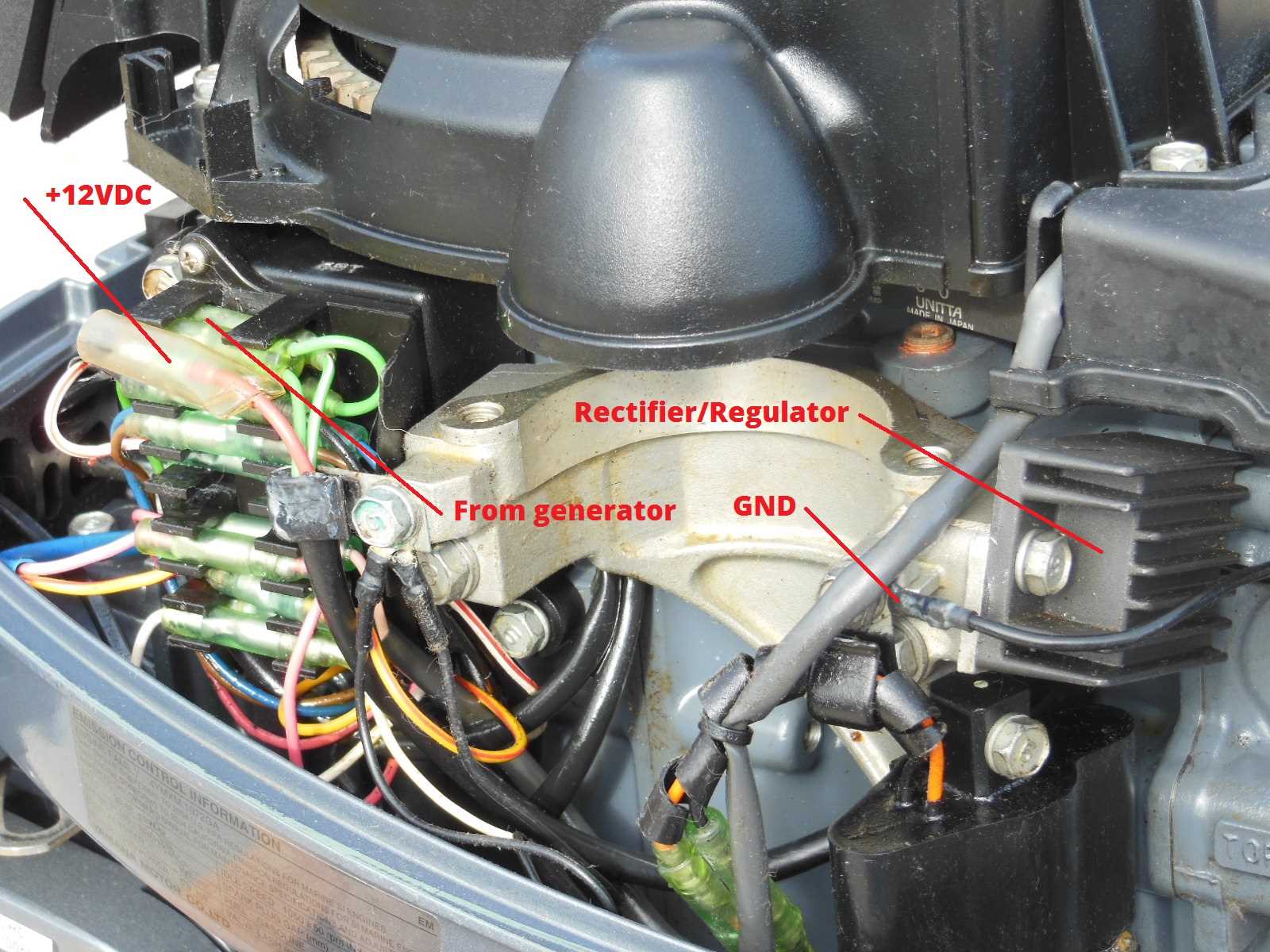

Frequent checks of the vital components are necessary for the engine to function correctly. Begin by examining the fuel system for any leaks or blockages. Additionally, ensure the oil level is appropriate, and the oil itself is clean, as it plays a crucial role in lubricating moving parts. It’s also important to inspect the cooling system to avoid overheating, which can cause serious damage.

Lubrication and Fluids

Changing the oil and other essential fluids at regular intervals is fundamental. Fresh oil ensures that moving parts operate smoothly without excessive friction, while clean fuel enhances combustion efficiency. Keep track of the recommended intervals for changing fluids to avoid buildup that could harm the engine’s performance. Regular replacement of lubricants and fluids will significantly enhance the durability of the motor.

By staying consistent with these maintenance

Routine Check-ups to Ensure Optimal Performance

Regular maintenance is essential for keeping your equipment in prime condition and preventing unnecessary issues. By consistently inspecting various components and making adjustments where necessary, you can enhance the reliability and longevity of the system. This section outlines key areas to focus on during routine evaluations, ensuring smooth operation and optimal performance.

Fluids: It is crucial to monitor fluid levels such as oil and coolant. Ensure that the levels are within the recommended range, and refill or replace them as needed to avoid any mechanical problems.

Filters: Regularly check both air and fuel filters. Clean or replace them if they show signs of clogging, as this can impact efficiency and lead to potential engine damage over time.

Inspect Components: Examine key elements such as the fuel system, spark

Troubleshooting Common Engine Issues

Understanding the root cause of performance problems in a small engine is crucial for effective maintenance and repair. Identifying common symptoms and their solutions can save time and prevent costly breakdowns. This section focuses on typical mechanical and operational concerns that may arise, along with practical advice on diagnosing and resolving them.

Starting Problems

If the motor fails to start or takes multiple attempts to engage, there are a few key areas to check. First, ensure the fuel supply is adequate and fresh, as stale fuel can hinder ignition. Examine the spark plug for signs of wear or fouling, as this can disrupt the electrical flow. Additionally, inspect the fuel line and filters for blockages that may restrict proper fuel delivery.

Power Loss and Stalling

Sudden

Recommended Fluids and Parts for Longevity

Proper maintenance is essential for ensuring the long-term performance and reliability of any mechanical system. By selecting the right lubricants and replacement components, you can extend the lifespan of your equipment and reduce the risk of premature wear or damage. This section outlines the most important fluids and parts that are recommended to keep your machine running smoothly over time.

- Engine Oil: Using high-quality oil that meets or exceeds the manufacturer’s specifications is critical for reducing friction and wear. Regular oil changes are necessary to keep the system lubricated and functioning properly.

- Gearcase Lubricant: This lubricant helps protect internal components from corrosion and excessive friction. Be sure to check and replace it according to the maintenance schedule to ensure smooth operation.

- Fuel Filter: A clean filter prevents debris and impurities from entering the system, ensuring optimal performance. Replace the fuel filter regularly to avoid