For those who rely on robust agricultural equipment, understanding the intricacies of your machinery is crucial. A well-structured resource can enhance the longevity and efficiency of your equipment, ensuring optimal performance in the field. This section serves as an essential tool for operators seeking to familiarize themselves with the operational aspects and maintenance requirements of their vehicles.

Within this guide, you will find detailed insights tailored to help you navigate the various features and functions of your equipment. From routine maintenance tasks to troubleshooting common issues, the information presented here aims to empower users with the knowledge needed to keep their machinery in peak condition.

Whether you are a seasoned operator or a newcomer to the world of farming machinery, this resource is designed to address your needs effectively. By following the recommendations and guidelines outlined, you can maximize productivity and ensure your equipment remains a reliable partner in your agricultural endeavors.

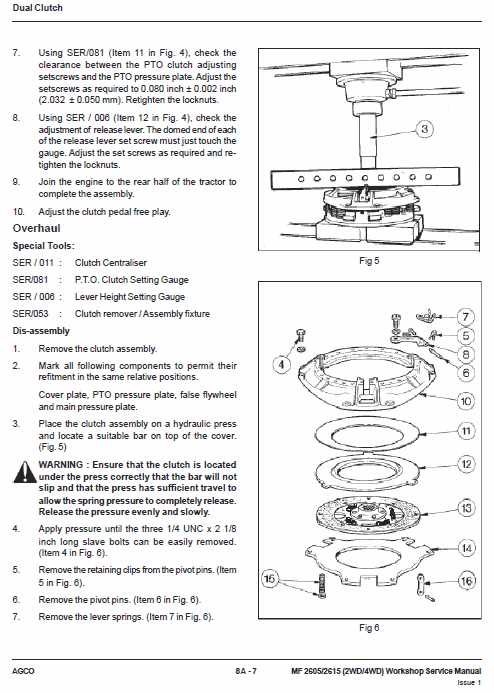

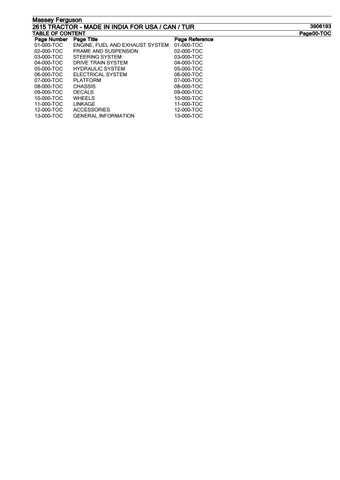

Understanding Massey Ferguson 2615 Features

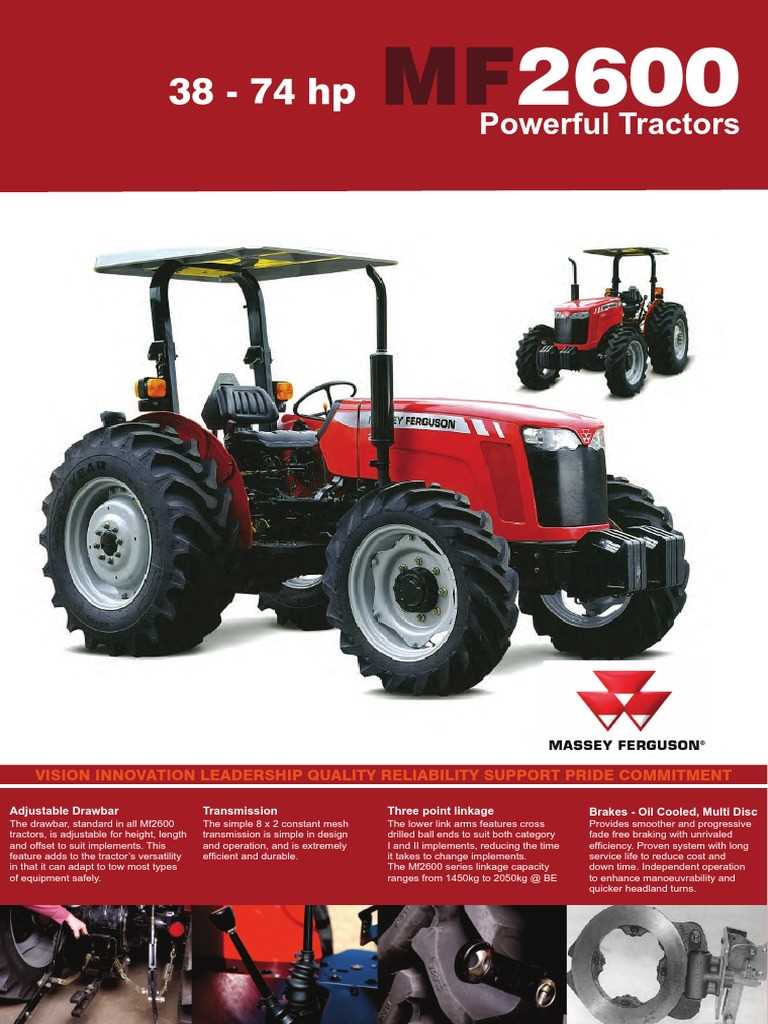

This section explores the distinctive attributes of a specific agricultural vehicle, highlighting its functionalities and advantages for users in the farming industry. Understanding these features can enhance efficiency and productivity on the field.

Key Characteristics

- Engine Performance: The vehicle is equipped with a powerful engine that ensures optimal performance under various conditions.

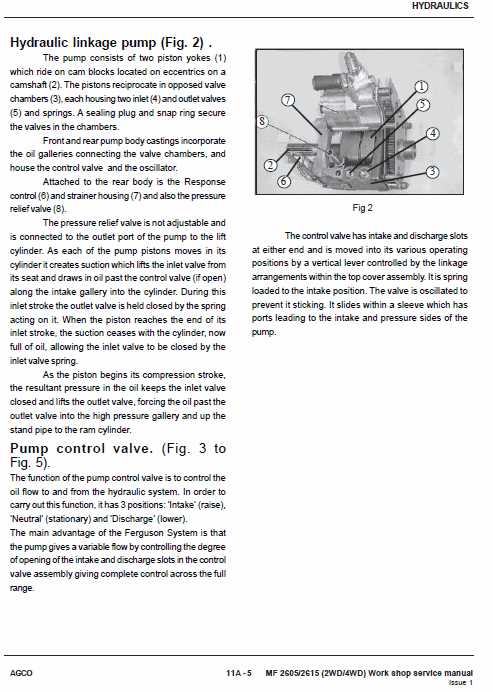

- Hydraulic System: A robust hydraulic system allows for smooth operation of attachments and implements, enhancing versatility.

- Comfortable Cab Design: The ergonomic cabin is designed for operator comfort, providing ease of use during long hours of operation.

- Durability: Built with high-quality materials, this machine is designed to withstand the rigors of daily agricultural tasks.

Technological Innovations

- Advanced Control Systems: Modern controls provide intuitive operation, allowing for greater precision in handling.

- Fuel Efficiency: Innovative engineering optimizes fuel consumption, reducing operational costs significantly.

- Safety Features: Equipped with essential safety mechanisms, ensuring the protection of the operator during use.

- Easy Maintenance: The design facilitates straightforward maintenance procedures, minimizing downtime and enhancing productivity.

Maintenance Tips for Optimal Performance

Regular upkeep is essential to ensure your machinery operates at its best. By adhering to a structured maintenance routine, you can enhance efficiency, extend the lifespan of your equipment, and prevent unexpected breakdowns. This section outlines key practices that will help you achieve optimal performance and reliability.

Routine Inspections

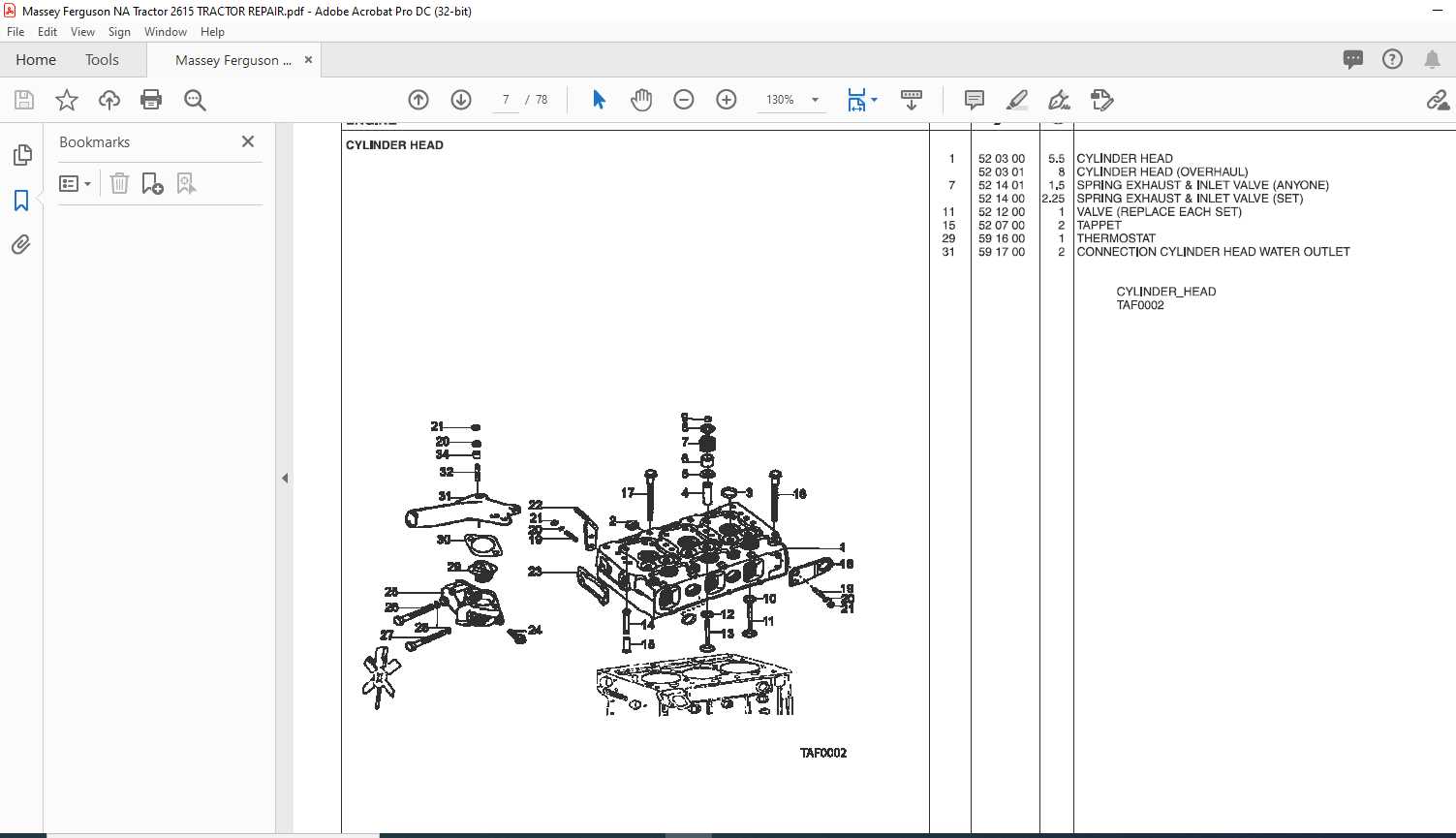

Conducting systematic checks is crucial. Regularly inspect critical components such as the engine, hydraulic systems, and belts. Look for signs of wear and tear, leaks, or unusual noises. Early detection of issues can save time and resources, preventing costly repairs down the line.

Fluid Checks and Changes

Maintaining proper fluid levels is vital for smooth operation. Ensure that engine oil, hydraulic fluid, and coolant are at recommended levels. Periodically change these fluids according to the manufacturer’s recommendations. Clean fluids help in reducing friction and overheating, contributing to the overall efficiency of the machine.

By following these maintenance tips, you can significantly improve the performance and reliability of your equipment, ensuring it meets your operational needs effectively.

Common Issues and Troubleshooting Guide

This section addresses frequent problems that operators may encounter and provides practical solutions. Understanding these common issues can help maintain optimal performance and extend the lifespan of your equipment.

Typical Problems

| Issue | Possible Causes | Solutions |

|---|---|---|

| Engine Won’t Start | Dead battery, fuel blockage, or faulty ignition. | Check battery charge, inspect fuel lines, and test the ignition system. |

| Overheating | Low coolant level, clogged radiator, or faulty thermostat. | Inspect coolant levels, clean the radiator, and replace the thermostat if necessary. |

| Transmission Issues | Low fluid levels or worn components. | Check and refill fluid levels; inspect for wear and replace parts as needed. |

Maintenance Tips

Regular inspections and maintenance can prevent many common problems. Always refer to the recommended service intervals and ensure that all fluid levels are adequate. Keeping the machine clean and free of debris also helps in avoiding mechanical issues.