Operating complex machinery in agriculture requires a clear understanding of its features and functions. Whether you’re working in the field or performing maintenance, having an informative resource at hand is crucial for smooth and efficient operation. A detailed guide serves as an invaluable tool to ensure that each function is used optimally, reducing downtime and enhancing productivity.

In the sections ahead, we’ll explore various aspects of machine management, from daily maintenance to troubleshooting. This guide aims to empower users with practical knowledge, offering insights into the best practices for keeping your equipment in top condition. By following these guidelines, you can significantly extend the lifespan of your machinery and ensure it operates at peak performance.

Maintaining your equipment doesn’t have to be complicated. With a clear plan and regular checks, you can avoid common issues and keep things running smoothly. In this guide, you’ll find the essential steps to follow, along with useful tips for handling more advanced tasks. Equip yourself with the knowledge to stay on top of every situation.

Maintenance Tips for Your Equipment

Regular upkeep is crucial to ensure the longevity and smooth operation of agricultural machinery. Adopting a consistent approach to service routines can help prevent unexpected breakdowns and maintain efficiency in the field.

Inspecting Essential Components

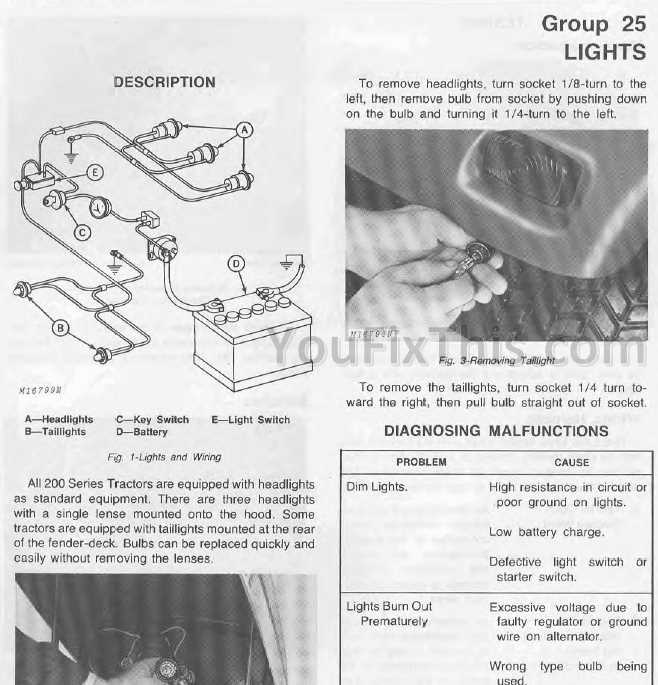

Frequent checks of vital systems such as the engine, hydraulics, and tires will allow for early detection of potential issues. Paying close attention to fluid levels, hose conditions, and electrical wiring is important for keeping everything running at peak performance. Address any wear or damage promptly to avoid larger repairs down the line.

Lubrication and Cleaning

Applying lubrication to moving parts is necessary to reduce friction and extend the lifespan of mechanical systems. Keeping these areas free of dust, dirt, and other debris ensures smoother operation and prevents unnecessary strain on the machinery. Regular cleaning also minimizes the risk of corrosion, especially in challenging weather conditions.

How to Keep Your Tractor in Top Shape

Maintaining your tractor is essential to ensure its performance remains reliable and efficient over time. Regular care not only extends its lifespan but also helps prevent unexpected issues during operation. Following a few key practices will keep your equipment in excellent working condition.

Regular Maintenance Routine

- Check engine oil levels frequently and replace the oil according to the recommended schedule.

- Inspect the air filter and clean or replace it to ensure optimal engine performance.

- Grease all moving parts to reduce wear and tear on the mechanical components.

- Examine belts and hoses for any signs of damage or wear, replacing them as necessary.

Cleanliness and Storage

Proper cleaning and storage are also vital for preserving the condition of your machine. Keeping

Engine Care and Performance

Maintaining optimal functionality and longevity of your machinery’s power unit is crucial for effective operation. Proper attention to care not only enhances efficiency but also reduces the likelihood of costly repairs. Understanding the key aspects of engine maintenance can significantly impact overall performance.

Regular Inspections are essential for identifying potential issues early. Check fluid levels frequently, including oil and coolant, to ensure they are within the recommended ranges. Regularly inspect filters and replace them as needed to keep contaminants from entering the engine, which can hinder performance.

Routine Maintenance tasks such as changing the oil at specified intervals and replacing air filters can dramatically improve efficiency. Clean components, such as spark plugs, contribute to better fuel combustion, enhancing power output. Follow the recommended service intervals for maintenance to achieve optimal results.

Operating Conditions play a significant role in engine performance. Ensure that the unit is used within its specified limits to prevent unnecessary strain. Avoid overloading, as this can lead to overheating and premature wear. Understanding the environment in which the machinery operates helps in adjusting maintenance schedules accordingly.

Fuel Quality also affects engine efficiency. Using high-quality fuel reduces deposits and improves combustion efficiency. Regularly monitoring fuel filters is essential to prevent blockages that could impair performance.

Ensuring Optimal Operation of Your Equipment

Maintaining peak performance of your machinery is essential for achieving efficiency and longevity. Regular attention to various aspects of operation can prevent unnecessary breakdowns and enhance productivity.

To achieve the best results, consider the following practices:

- Conduct routine inspections to identify wear and tear.

- Ensure proper lubrication of moving parts to reduce friction.

- Keep the equipment clean to prevent the buildup of dirt and debris.

In addition to these maintenance tasks, it’s crucial to follow the recommended usage guidelines:

- Utilize the correct fuel type and quality to optimize performance.

- Monitor operating temperatures to prevent overheating.

- Adjust settings according to the specific task requirements.

By implementing these strategies, you can enhance the functionality and reliability of your machinery, ultimately leading to greater operational success.

Troubleshooting Common Tractor Issues

Addressing frequent difficulties encountered with agricultural machinery can significantly enhance performance and longevity. By identifying typical problems and understanding their potential causes, operators can implement effective solutions, ensuring optimal operation in various working conditions.

Below is a table summarizing common issues, possible causes, and suggested remedies for efficient troubleshooting:

| Common Issue | Possible Causes | Suggested Remedies |

|---|---|---|

| Engine Won’t Start | Empty fuel tank, faulty battery, ignition issues | Refill fuel, check battery connections, inspect ignition system |

| Poor Performance | Clogged air filter, improper fuel mixture, worn spark plugs | Clean or replace air filter, adjust fuel mixture, replace spark plugs |

| Overheating | Low coolant level, blocked radiator, malfunctioning thermostat | Check and refill coolant, clean radiator, inspect thermostat operation |

| Hydraulic System Failure | Low hydraulic fluid, leaks in lines, damaged pump | Refill hydraulic fluid, repair leaks, replace damaged components |

| Unusual Noises | Lack of lubrication, worn bearings, loose components | Lubricate moving parts, replace worn bearings, tighten loose fittings |