For those working in industries requiring robust and reliable machinery, having detailed instructions on how to handle and maintain their equipment is essential. Understanding the inner workings of your machine can greatly enhance performance and longevity. This guide provides crucial insights to help ensure the smooth operation of your machine, maximizing both productivity and safety on the job.

With various moving parts and advanced mechanical systems, keeping up with regular maintenance and troubleshooting can seem daunting. However, a well-structured guide can be your go-to resource for navigating these challenges. From routine servicing to more complex mechanical adjustments, this guide will assist in ensuring optimal functionality.

Knowing how to properly care for your equipment not only reduces downtime but also extends its life, allowing you to get the most out of

Essential Maintenance Tips for John Deere 317 Skid Steer

Proper upkeep is crucial for ensuring the longevity and efficiency of your compact machinery. By adhering to a regular maintenance schedule, operators can prevent unexpected breakdowns and enhance the overall performance of their equipment. This section provides valuable insights into essential care practices that every user should follow to keep their machinery in top condition.

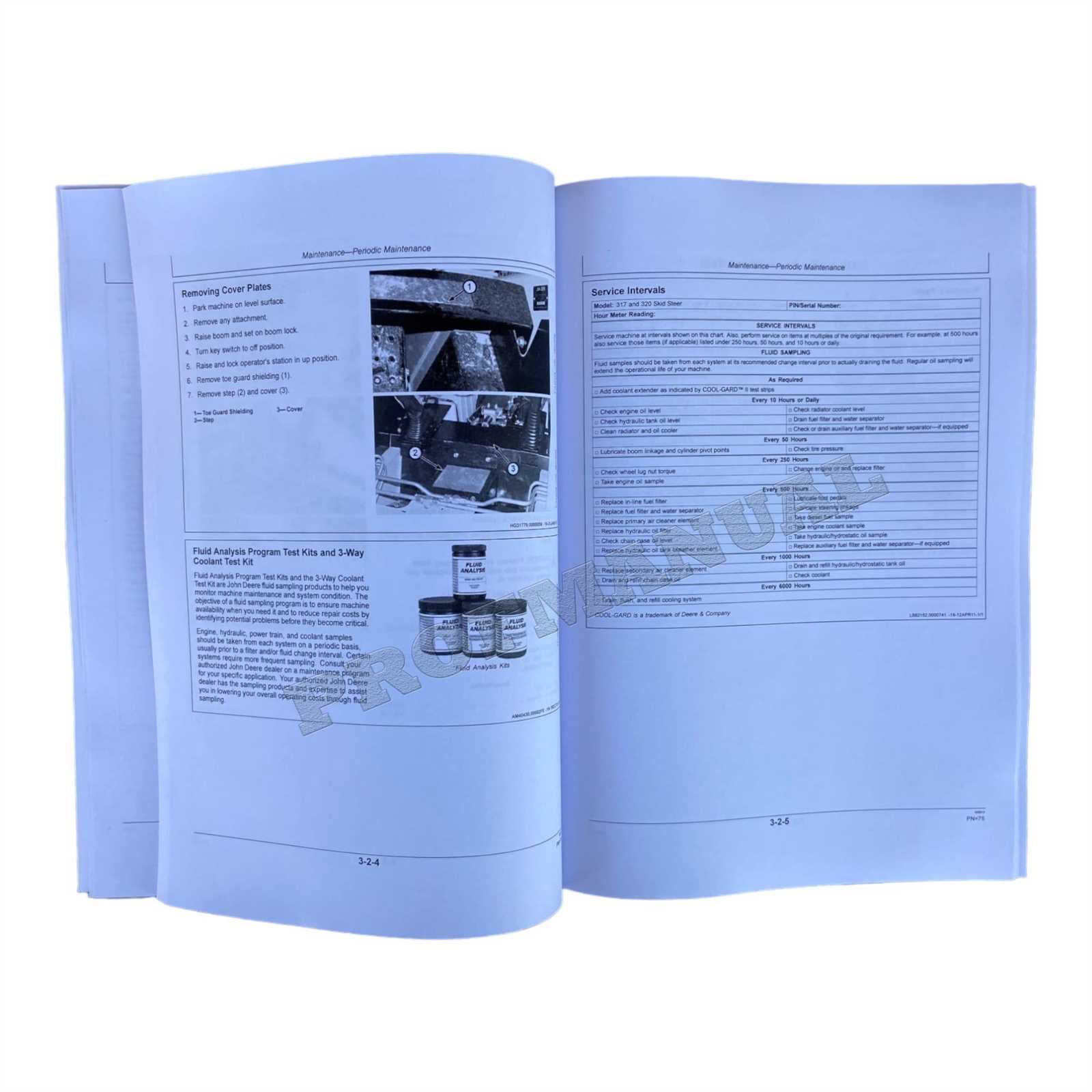

One of the first steps in maintenance is to regularly check fluid levels, including engine oil, hydraulic fluid, and coolant. Keeping these fluids at the recommended levels not only ensures smooth operation but also prevents excessive wear and tear on internal components. Regularly replacing these fluids according to the manufacturer’s recommendations will help maintain optimal functionality.

Inspecting filters is equally important. Clean or replace air and fuel filters as necessary to ensure that the engine receives adequate airflow and fuel supply. Clogged filters can lead to decreased performance and efficiency, making this a vital aspect of regular care.

Additionally, it’s essential to monitor tire pressure and tread condition. Properly inflated and well-maintained tires contribute to better traction and maneuverability, which are crucial for effective operation. Regularly check for any signs of wear or damage and replace tires as needed to maintain optimal performance.

Another critical maintenance tip involves the thorough inspection of belts and hoses. Look for signs of wear, fraying, or cracking, as damaged belts and hoses can lead to catastrophic failures. Replacing them promptly can save time and money in the long run.

Lastly, keeping the exterior clean and free from debris is fundamental. Regularly washing the machine helps prevent corrosion and allows for easier detection of any potential issues. By following these essential care practices, operators can ensure their equipment remains reliable and efficient for years to come.

Understanding the John Deere 317 Skid Steer Controls

The operation of a compact loader requires familiarity with its various functionalities. Mastering the interface is essential for maximizing efficiency and ensuring safety during use. This section delves into the key components that govern the machine’s performance, providing operators with valuable insights to enhance their experience.

Control Layout: The arrangement of levers, pedals, and buttons is designed for intuitive access. Understanding their placements can significantly reduce the learning curve, allowing users to quickly adapt to the equipment.

Levers: These pivotal components are responsible for the movement of the vehicle and its attachments. Typically, one lever controls the forward and backward motion, while the other manages the lateral movement. Familiarity with the sensitivity and responsiveness of these controls is crucial for precise navigation.

Pedals: In addition to levers, foot-operated mechanisms play a vital role in controlling speed and direction. Operators should practice using these pedals to enhance their ability to maneuver seamlessly in various environments.

Buttons and Switches: Various buttons activate specific features such as lights, attachments, and engine functions. Knowing the purpose of each switch allows for quick adjustments without diverting attention from the task at hand. Regularly reviewing the functions of these controls ensures optimal performance.

Safety Precautions: Understanding the control system also involves recognizing safety features. Always refer to safety guidelines to prevent accidents and ensure compliance with operational standards.

In summary, mastering the control system of this equipment is pivotal for effective operation. Continuous practice and attention to detail will cultivate proficiency, ultimately leading to a safer and more productive work experience.

Common Troubleshooting for John Deere 317 Skid Steer Owners

When operating heavy machinery, encountering issues is not uncommon. Understanding how to diagnose and resolve these problems can enhance efficiency and prolong the equipment’s lifespan. This section provides insights into typical challenges faced by operators and effective solutions to address them.

Identifying Common Issues

- Engine Not Starting: This may be due to a faulty battery, starter motor issues, or fuel supply problems.

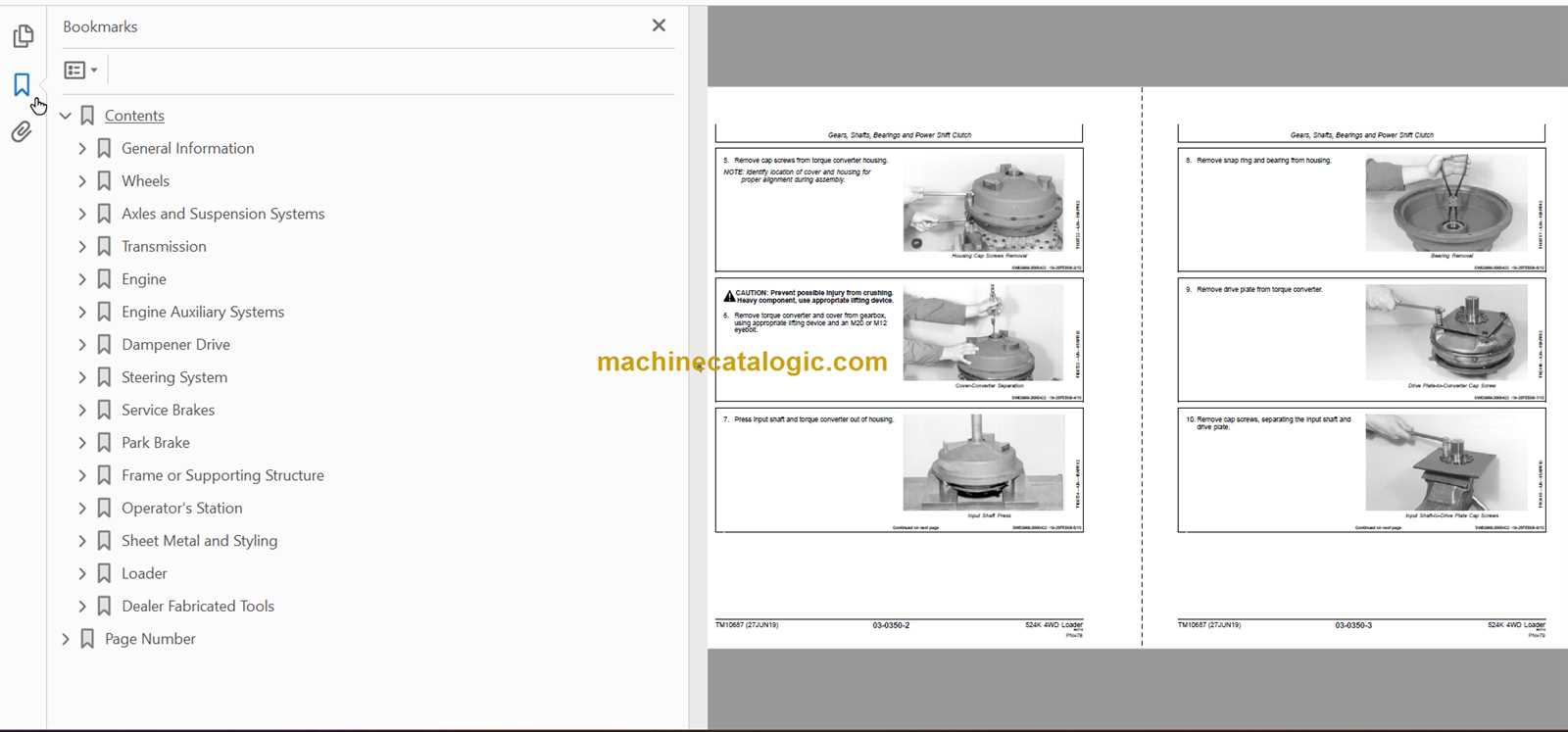

- Hydraulic Problems: Insufficient power or slow response can indicate low fluid levels or leaks in the hydraulic system.

- Overheating: This can result from clogged filters, low coolant levels, or malfunctioning cooling fans.

Troubleshooting Steps

- Check the Battery: Ensure connections are tight and terminals are free from corrosion.

- Inspect Fluid Levels: Regularly check hydraulic fluid, coolant, and oil levels to maintain proper function.

- Examine Belts and Hoses: Look for signs of wear or damage that could lead to performance issues.

- Test Electrical Systems: Use a multimeter to verify that electrical components are functioning correctly.

By addressing these common issues and following the outlined troubleshooting steps, operators can keep their equipment running smoothly and efficiently.