Understanding how to properly operate and maintain your outdoor equipment is essential for ensuring longevity and efficient performance. This guide provides clear instructions, practical tips, and essential safety precautions to help you get the most out of your machine. Whether you’re a beginner or an experienced user, this resource aims to simplify your experience by offering step-by-step directions.

We delve into the important features and functionalities of your machine, ensuring that each component is covered in detail. From starting the engine to adjusting various settings, this comprehensive resource will help you navigate every aspect with ease. By following these guidelines, you can improve efficiency and prevent common issues.

In addition to operational insights, the guide also emphasizes regular upkeep. Proper maintenance routines are outlined to keep your equipment in top condition, ensuring that it runs smoothly over time. By adhering to the recommended practices, you’ll extend the lifespan of your machine and enhance its overall performance.

Maintenance Tips for Long-Lasting Performance

Consistent upkeep is crucial for ensuring the durability and efficiency of your equipment. By adopting regular care routines, you can significantly extend the lifespan of your machinery and maintain optimal functionality throughout its use.

Regular Cleaning and Inspection

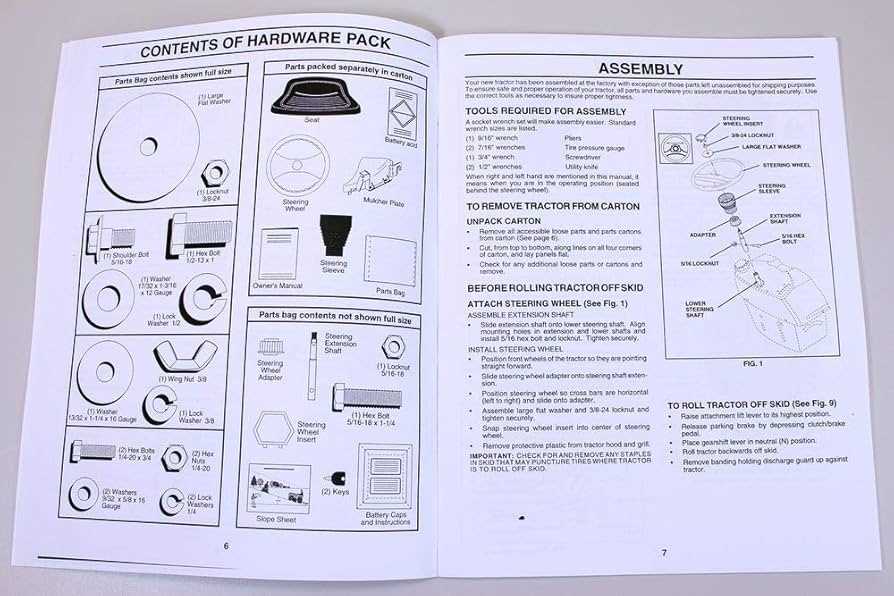

To prevent the buildup of debris and dirt, it is essential to clean your equipment after each use. Thorough inspections of all mechanical components can help identify wear or potential issues early, reducing the risk of major failures. Always check for any loose parts and tighten them as needed.

Lubrication and Component Care

Ensuring proper lubrication of all moving parts is a key factor in maintaining smooth operation. Use the recommended type of oil or grease and apply it according to the service schedule. Pay special

Essential Checks Before Each Use

Before operating your equipment, it’s important to conduct several routine inspections to ensure smooth and safe performance. These steps help maintain efficiency and avoid potential issues that may arise during operation.

Inspecting the Engine

- Check the fuel level and top up if necessary.

- Ensure the oil is at the correct level and is clean.

- Inspect the air filter for dirt or damage, cleaning or replacing it if needed.

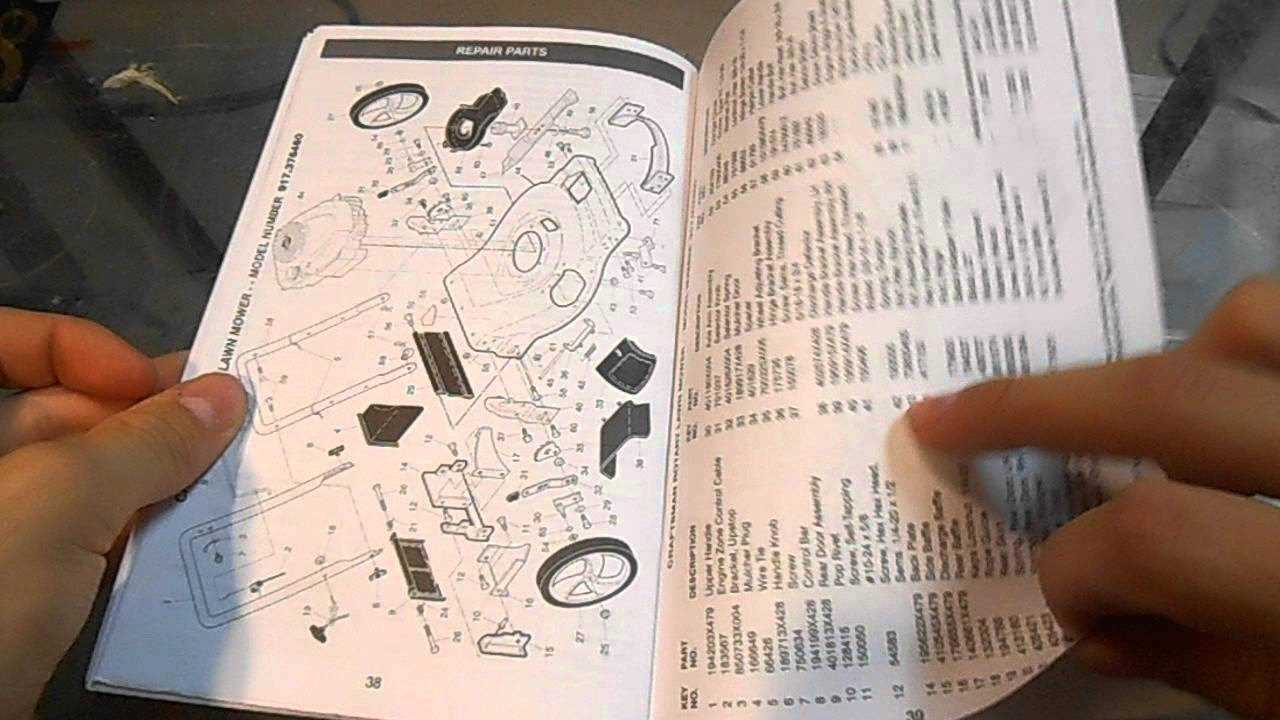

Examining Moving Parts

- Ensure the blades are sharp and free from any debris.

- Check for any loose bolts or screws on mechanical parts.

- Inspect the wheels for proper alignment and secure attachment.

By following these simple checks, you can keep your equipment running efficiently and reduce the chances of unexpected issues during operation.

Best Practices for Engine Care

Proper maintenance is essential for ensuring the long-term efficiency and durability of any engine. Regular inspections, cleaning, and timely servicing help prevent breakdowns and keep the machine operating smoothly. Following a consistent maintenance routine can significantly extend the lifespan of the motor, while also ensuring optimal performance throughout its usage.

Here are some best practices to follow when taking care of an engine:

| Maintenance Task | Recommended Frequency |

|---|---|

| Check and replace oil | Every 25 hours of operation or as recommended |

| Clean or replace air filter | Every season or when clogged |

| Inspect spark plug | Once per season or every 100 hours of use |

| Fuel system check |