Having access to a well-structured reference guide is essential for anyone utilizing a compact loader. This resource provides crucial insights into the machine’s functionalities, maintenance routines, and safety precautions. Understanding these elements ensures efficient operation and longevity of the equipment, allowing users to maximize its potential on the job site.

Within this guide, you will discover vital information regarding various components and their specific roles. Comprehension of these features is paramount for both novice and experienced operators, as it facilitates informed decision-making during operation. Familiarizing oneself with these details can lead to improved productivity and a safer working environment.

Furthermore, the manual emphasizes regular upkeep, which is crucial for maintaining optimal performance. By adhering to recommended service schedules and performing routine checks, users can prevent unexpected breakdowns and ensure smooth operation. This not only enhances efficiency but also contributes to the overall safety of all personnel involved.

Comprehensive Guide to C238 Operation

This section provides an in-depth overview of operating principles and best practices for effective use of your machinery. Understanding the intricacies of functionality not only enhances performance but also ensures longevity and reliability. This guide is tailored to help users navigate the various features and capabilities, ensuring optimal operation across different tasks.

1. Familiarization with Controls: Before engaging with the equipment, it is essential to become acquainted with all operational controls and indicators. Each lever, button, and gauge serves a specific purpose, contributing to overall efficiency and safety during use. Proper knowledge of these elements minimizes the risk of errors and promotes smoother operation.

2. Safety Protocols: Adhering to safety guidelines is paramount. Always wear appropriate personal protective equipment and ensure that all safety features are functional. Regularly inspect the machine for any wear or damage, and address any issues before starting work. This proactive approach safeguards both the operator and the equipment.

3. Maintenance Practices: Regular maintenance is crucial for maintaining performance standards. Establish a routine that includes checking fluid levels, cleaning filters, and inspecting belts and hoses. Keeping the machinery in top condition not only extends its lifespan but also enhances productivity during operation.

4. Efficient Operation Techniques: Employing best practices during operation can significantly impact efficiency. For example, adjusting speed settings according to the task can optimize fuel consumption and enhance output quality. Understanding the load capacities and operating limits ensures that tasks are completed safely and effectively.

5. Troubleshooting Common Issues: Familiarize yourself with common challenges that may arise during use. Quick identification of problems allows for prompt solutions, minimizing downtime. Regular training and updates on potential issues empower operators to manage equipment confidently and effectively.

Maintenance Tips for New Holland Machines

Regular upkeep is essential for the longevity and performance of any heavy-duty machinery. By following a consistent maintenance routine, operators can ensure optimal functionality and reduce the likelihood of unexpected breakdowns. This section provides practical advice on how to care for your equipment, ensuring it remains reliable in the long run.

Regular Inspection and Cleaning

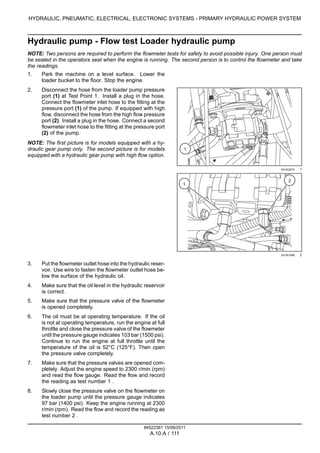

Inspecting your equipment on a routine basis helps identify any signs of wear or damage. Pay close attention to moving parts, hydraulic lines, and connections. Cleaning the machine, especially after prolonged use, prevents debris buildup, which can lead to corrosion or operational issues. Use appropriate cleaning agents and avoid high-pressure water on sensitive components.

Lubrication and Fluid Checks

Proper lubrication is crucial for maintaining the smooth operation of your equipment’s moving parts. Make sure to apply high-quality grease at recommended intervals. Additionally, monitor fluid levels, including hydraulic, engine oil, and coolant. Keeping these fluids within the specified range not only prevents damage but also ensures the machine operates efficiently.

Tip: Always refer to your model-specific guidelines to confirm maintenance intervals and recommended products for servicing. This helps prevent potential issues and extends the equipment’s operational lifespan.

Safety Protocols for C238 Users

Understanding and following essential safety measures is crucial when handling this type of equipment. This ensures both the operator’s well-being and the longevity of the machinery. Here’s an overview of key precautions to keep in mind while working with the equipment.

Pre-Operational Checks

- Inspect all controls and ensure they function correctly before starting.

- Verify that all safety features, such as lights and alarms, are operational.

- Check for any visible damage or leaks around the machine and repair them before use.

During Operation

- Always wear appropriate protective gear, including helmets, gloves, and safety boots.

- Maintain clear communication with surrounding workers, using signals or radios when necessary.

- Avoid operating on uneven terrain or slopes without proper assessment of the ground stability.

- Never exceed the recommended load limits to prevent tipping or damage.

By adhering to these guidelines, users can significantly reduce the risk of accidents and ensure a safer working environment.