In the realm of farming, the effective operation and maintenance of agricultural machinery play a crucial role in enhancing productivity. This section aims to provide valuable insights into the best practices and essential knowledge required for users of specific equipment designed for agricultural tasks. Understanding the intricacies of machinery operation not only ensures efficiency but also promotes safety and longevity of the equipment.

The guidance presented here will cover a variety of aspects, from routine maintenance to troubleshooting common issues. Users will gain insights into optimizing the functionality of their machines, allowing them to perform tasks with greater precision and ease. Whether you are an experienced operator or a novice, this resource is designed to equip you with the necessary tools to manage your equipment effectively.

Emphasizing the importance of following recommended procedures can lead to improved performance and reduced downtime. Familiarity with operational guidelines will empower users to address challenges confidently, ultimately contributing to a more successful farming experience. Through careful attention to detail and adherence to best practices, users can ensure their machinery operates at its full potential.

Regular upkeep is essential for ensuring the longevity and efficient functioning of your agricultural equipment. By adhering to systematic maintenance practices, you can prevent common issues and enhance productivity. This section outlines key recommendations to help you maintain your machinery effectively.

Routine Inspections

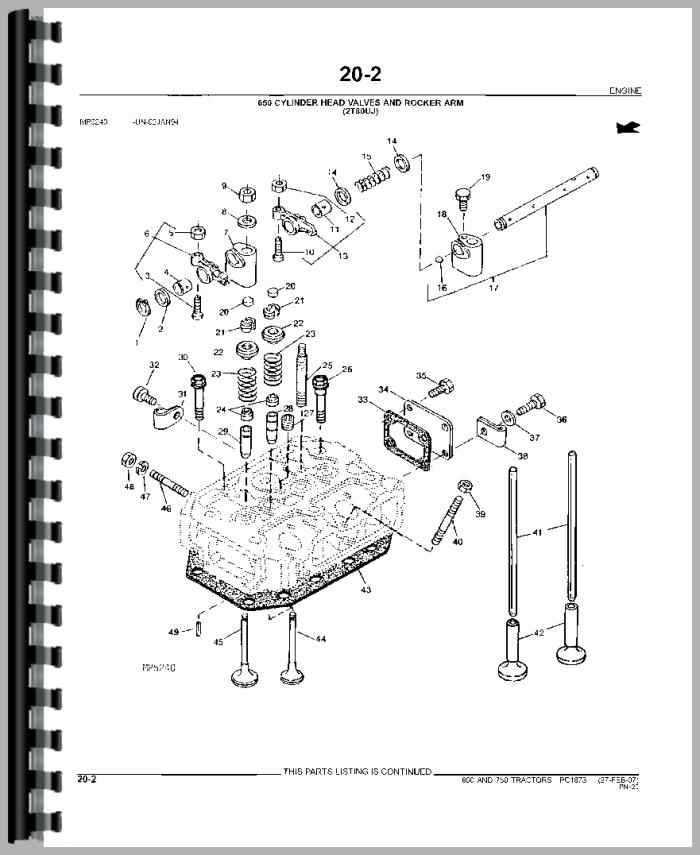

Conducting periodic assessments is crucial in identifying potential problems before they escalate. Ensure that all vital components are checked regularly, focusing on fluid levels, belts, and filters. Keeping detailed records of these inspections will help in tracking performance over time.

Cleaning and Lubrication

Maintaining cleanliness is vital for optimal operation. Regularly remove dirt and debris from the exterior and working parts of your equipment. Additionally, proper lubrication of moving components minimizes wear and tear, allowing for smoother functionality.

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Fluid Check | Weekly | Ensure proper levels for oil, coolant, and hydraulic fluids. |

| Filter Replacement | Every 100 hours | Replace air and fuel filters as needed. |

| Visual Inspection | Daily | Look for leaks, wear, and damage to components. |

| Cleaning | After each use | Remove dirt and debris from critical areas. |

Troubleshooting Common Issues Effectively

Addressing frequent problems with agricultural machinery is crucial for maintaining optimal performance and longevity. Understanding the typical challenges that may arise can help operators quickly diagnose and resolve issues, minimizing downtime and enhancing productivity. This section provides insights into effective troubleshooting methods.

Firstly, it is important to identify the symptoms of the issue. Whether it is unusual noises, poor performance, or operational failures, recognizing these signs early can lead to quicker resolutions. Regular inspections and preventive maintenance are essential practices that can prevent many common complications from escalating.

Secondly, employing a systematic approach is vital. Start by checking the most accessible components, such as fluid levels and filters. If the problem persists, refer to diagnostic tools or consult troubleshooting guides specific to the equipment. Keeping detailed records of past issues and their resolutions can also be beneficial for future reference.

Finally, do not hesitate to seek professional assistance when needed. While many problems can be resolved independently, some issues may require expert intervention. Building a good relationship with a qualified service provider can ensure that you have the support necessary to tackle more complex challenges.