This section provides essential insights for individuals managing a specific type of agricultural machinery. Understanding the functionalities, maintenance, and operational guidelines is crucial for maximizing performance and ensuring longevity.

Users will find detailed instructions that cover various aspects, from routine upkeep to troubleshooting common issues. The goal is to empower operators with the knowledge needed to navigate their equipment effectively and efficiently.

By adhering to the recommended practices outlined herein, operators can enhance their experience and optimize the capabilities of their machinery. This resource serves as a valuable tool for both new and experienced users alike.

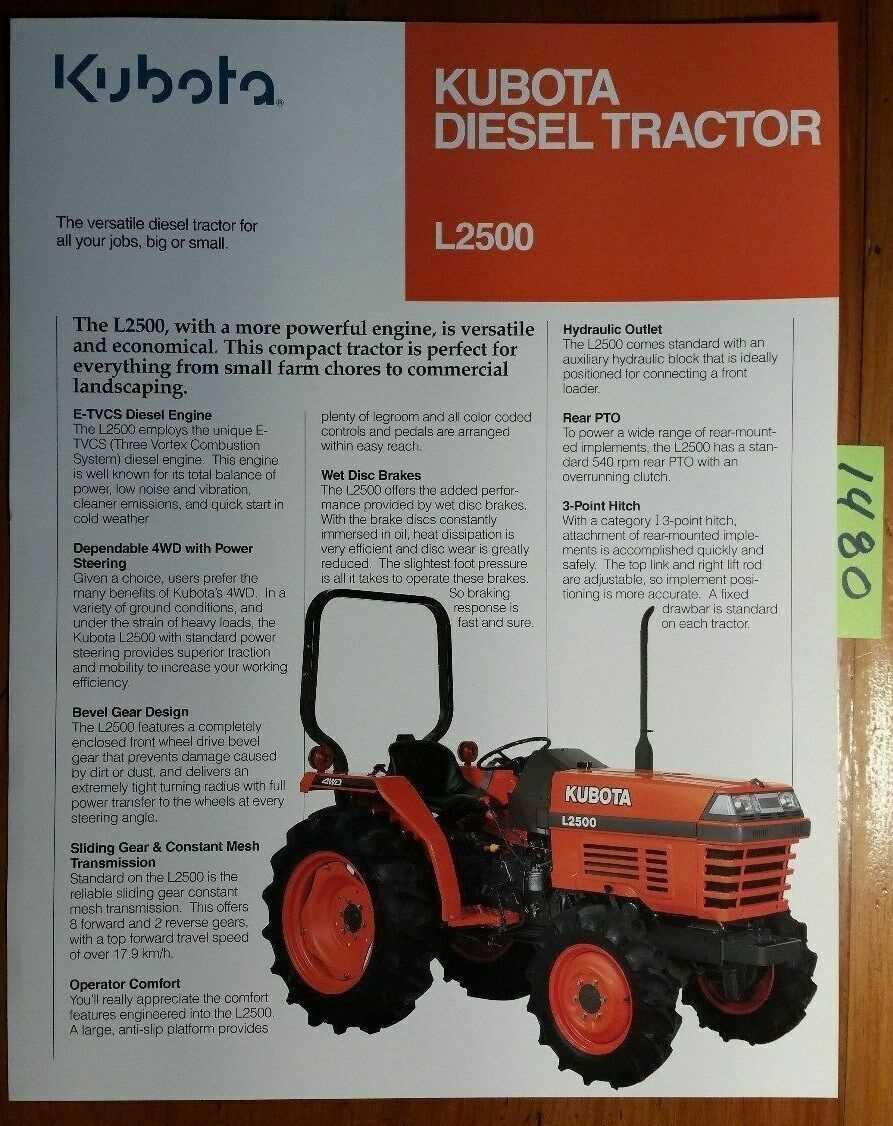

This section aims to provide an overview of the significant characteristics and advantages associated with this compact utility vehicle. Understanding these essential elements can assist users in optimizing their experience and enhancing operational efficiency.

Key Functional Attributes

The vehicle is equipped with a range of functional features designed to improve performance and versatility. Some of the notable attributes include:

- Powerful engine options for varied tasks.

- Efficient transmission systems ensuring smooth operation.

- Advanced hydraulic capabilities for enhanced attachment use.

User-Friendly Design

Attention to ergonomic design ensures ease of use and comfort during operation. Key aspects include:

- Intuitive controls for straightforward handling.

- Comfortable seating arrangements for prolonged use.

- Accessible maintenance points for quick servicing.

Versatility in Applications

This compact machine is versatile, making it suitable for a wide range of applications. Its adaptability includes:

- Capability to attach various implements for different tasks.

- Utilization in agriculture, landscaping, and construction.

- Compact size for maneuvering in tight spaces.

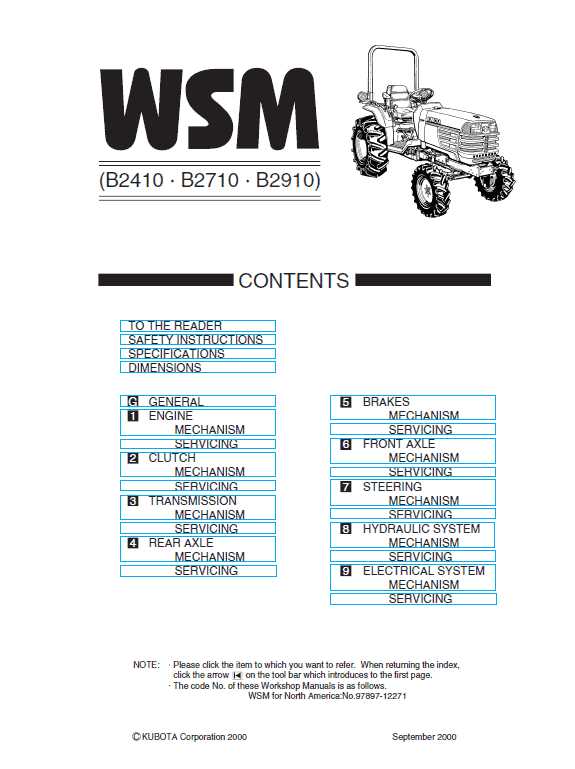

Maintenance Guidelines for Optimal Performance

Ensuring peak efficiency and longevity of your agricultural machinery requires a systematic approach to upkeep. Regular maintenance not only enhances performance but also prevents potential issues that can arise from neglect. Adopting a comprehensive maintenance routine will help in achieving the best operational results.

Regular Inspection and Servicing

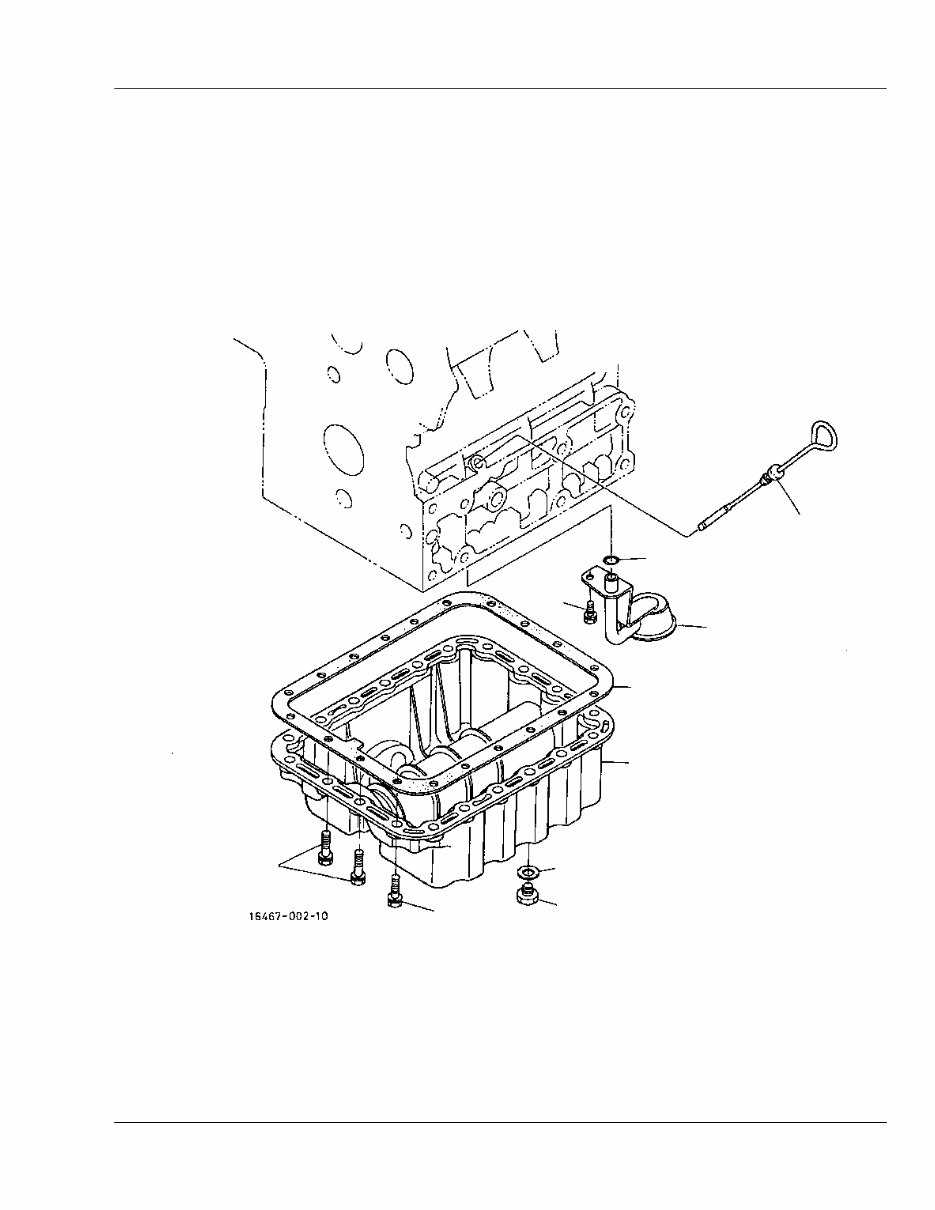

Routine checks are essential to identify any wear and tear before they escalate into major problems. Key components such as the engine, hydraulic systems, and electrical connections should be examined periodically. Replacing filters and fluids at recommended intervals is crucial to maintain optimal functionality. Regular servicing contributes significantly to the overall health of the equipment.

Proper Cleaning and Storage

Keeping your machinery clean plays a vital role in its maintenance. After each use, remove dirt and debris to prevent buildup that can hinder performance. Additionally, storing equipment in a dry, sheltered area protects it from environmental factors that could lead to corrosion and damage. Implementing these practices ensures that your machinery remains in excellent condition for future tasks.

Safety Precautions When Operating the Tractor

Ensuring safety during the operation of heavy machinery is essential to prevent accidents and injuries. Proper awareness and adherence to safety measures can significantly reduce risks associated with agricultural tasks.

Always wear appropriate protective gear, such as helmets, gloves, and sturdy footwear, to minimize the chance of injuries. Additionally, ensure that clothing is fitted correctly to avoid entanglement in moving parts.

Familiarize yourself with the equipment before use. Understanding the controls, features, and limitations of the tractor is crucial for safe operation. Always consult the safety guidelines provided by the manufacturer.

Before starting the engine, check the area around the vehicle for obstacles or bystanders. Maintaining a clear workspace helps prevent accidents and allows for better maneuverability.

Follow proper starting procedures and avoid starting the machine while seated in the operator’s position. This practice reduces the risk of accidental movement and ensures that all safety protocols are followed.

While operating the machinery, maintain a safe speed and be mindful of terrain changes. Sudden accelerations or decelerations can lead to loss of control, especially on slopes or uneven ground.

Finally, keep the work area organized and free from debris. A clutter-free environment enhances visibility and reduces the likelihood of accidents during operation.