In this section, we delve into the essential aspects of utilizing a versatile compact loader, designed to enhance productivity and efficiency in various tasks. Understanding the operational features and maintenance requirements is crucial for ensuring optimal performance and longevity of the equipment.

Whether you are familiar with this type of machinery or new to it, having access to detailed instructions and insightful tips can significantly improve your experience. This resource aims to provide valuable information that empowers users to navigate the functionalities and care procedures effectively.

By familiarizing yourself with the key components and recommended practices, you can maximize the potential of your compact loader. Regular upkeep and adherence to operational guidelines not only prevent potential issues but also contribute to the overall safety and effectiveness of your work.

Overview of Bobcat S590 Features

The compact loader is designed to excel in various work environments, showcasing a blend of versatility and power. This machine offers an array of functionalities that cater to different tasks, making it an ideal choice for construction and landscaping professionals.

Power and Performance: Equipped with a robust engine, this model delivers impressive horsepower, enabling it to tackle heavy-duty projects with ease. Its high lifting capacity allows operators to manage larger loads efficiently.

Compact Design: The streamlined build of this loader enhances maneuverability, allowing access to tight spaces where larger machines may struggle. This feature is particularly beneficial for urban construction sites and residential landscaping.

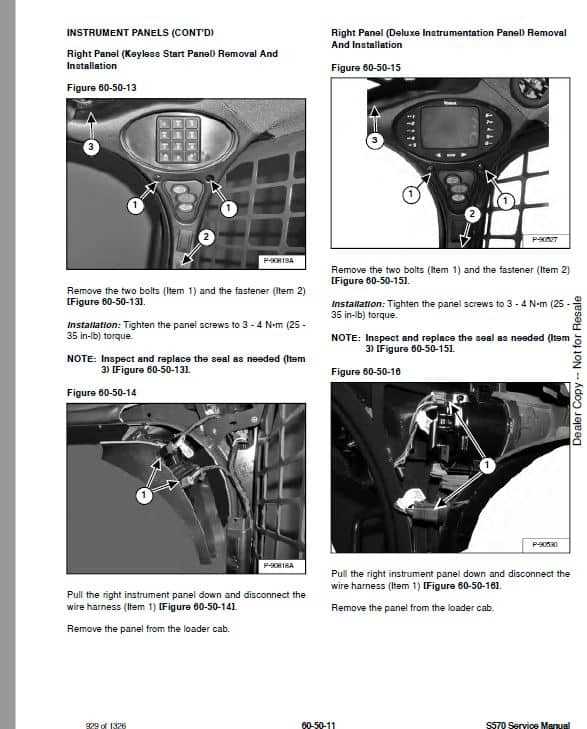

User-Friendly Controls: Designed with the operator in mind, the intuitive control layout simplifies operation, reducing the learning curve for new users. Advanced features like joystick controls and touchscreen displays provide seamless interaction with the equipment.

Attachment Versatility: This loader supports a wide range of attachments, from buckets to forks, making it adaptable for various tasks. This versatility not only increases productivity but also ensures that the machine can evolve with changing project requirements.

Durability: Built with high-quality materials, this machine is designed to withstand the rigors of demanding work environments. Its rugged construction ensures longevity, minimizing maintenance costs and downtime.

Maintenance Guidelines for Optimal Performance

To ensure the highest efficiency and longevity of your equipment, regular upkeep is essential. Adhering to a structured maintenance schedule not only enhances operational reliability but also minimizes unexpected downtime. A well-maintained machine operates at peak performance, contributing to overall productivity.

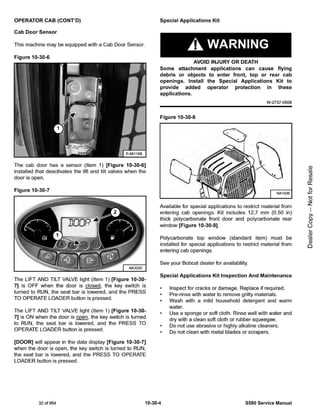

Routine Inspections: Conduct frequent checks on key components such as hydraulic systems, engine performance, and safety features. Regular inspections help identify potential issues before they escalate, allowing for timely interventions.

Fluid Management: Properly managing fluids is crucial. Regularly change engine oil, hydraulic fluid, and coolant according to the manufacturer’s recommendations. Clean filters and ensure that fluid levels are maintained to prevent overheating and wear.

Cleaning and Lubrication: Keep the exterior and interior of the machine clean. Remove debris and dirt from critical areas to avoid damage. Lubricate moving parts as specified to ensure smooth operation and reduce friction.

Parts Replacement: Replace worn-out components promptly. Pay attention to belts, hoses, and filters, as neglecting these parts can lead to more significant issues and costly repairs.

Following these maintenance guidelines will help achieve optimal performance and extend the lifespan of your machinery.

Safety Tips for S590 Operators

Operating heavy machinery demands a high level of attention and adherence to safety protocols. Ensuring a safe working environment is essential for preventing accidents and injuries. This section outlines critical safety measures that every operator should implement to enhance their safety and that of those around them.

Pre-Operation Safety Checks

Before starting any tasks, conducting thorough inspections of the equipment is crucial. This process helps identify potential hazards and ensures that all systems are functioning properly.

| Safety Check | Importance |

|---|---|

| Fluid Levels | Ensures proper functioning and prevents breakdowns. |

| Brakes and Controls | Guarantees reliable stopping power and control during operation. |

| Safety Features | Verifies that all safety systems are operational to protect the operator. |

Personal Protective Equipment

Wearing appropriate personal protective gear is vital when operating heavy machinery. This gear helps minimize the risk of injury from potential hazards present on the job site.