For those who own and operate a compact agricultural vehicle, understanding its features and functionalities is crucial for maximizing efficiency and longevity. This comprehensive guide is designed to provide valuable insights into the intricacies of maintenance and operation. It serves as a reliable resource for navigating the various components and systems that ensure optimal performance.

Whether you’re a seasoned operator or a new enthusiast, having access to detailed information about your machinery can make a significant difference. From routine checks to troubleshooting common issues, knowing how to care for your equipment helps prevent costly repairs and enhances productivity. This section aims to empower users with the knowledge they need to confidently handle their tasks.

In addition to operational tips, this guide emphasizes safety protocols and best practices to ensure a secure working environment. Understanding the importance of proper handling techniques not only protects the machine but also safeguards the operator. Engage with the content to discover essential strategies that promote both efficiency and safety in your daily tasks.

Understanding Your Kubota B2320

Gaining insight into your compact utility vehicle enhances your operational experience and ensures optimal performance. This section provides essential information to help you appreciate the features and functionalities of your machine, enabling you to utilize it effectively in various tasks.

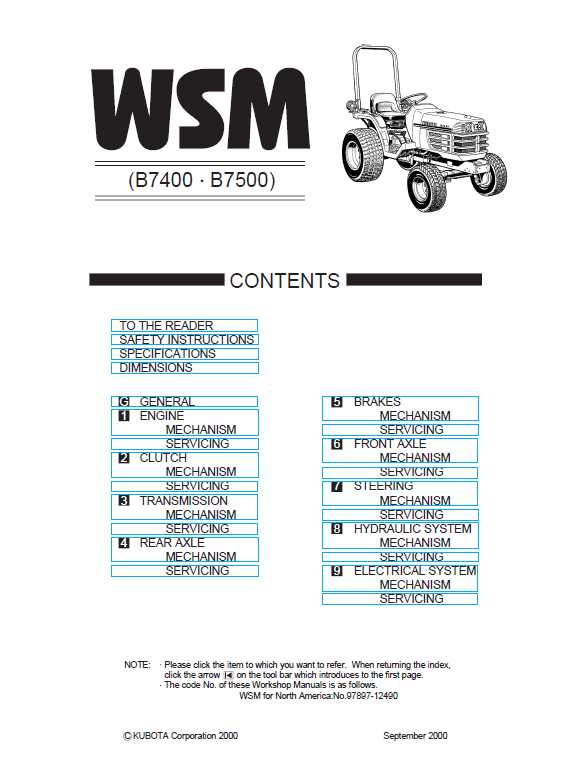

Key Features

Each vehicle in this category is designed with specific attributes that cater to diverse needs. Understanding aspects like engine capacity, transmission type, and hydraulic systems will empower you to tackle tasks efficiently. Familiarity with these elements is crucial for maximizing productivity.

Maintenance Essentials

Regular upkeep is vital for longevity and reliability. Engage with routine checks such as fluid levels, filter replacements, and tire conditions. Prioritizing these practices ensures your equipment remains in peak condition, ultimately enhancing performance and reducing downtime.

Essential Maintenance Tips for Longevity

Proper upkeep is crucial for ensuring the extended lifespan and optimal performance of your machinery. Regular attention to maintenance tasks not only enhances functionality but also prevents costly repairs and downtime. By adopting a systematic approach, owners can keep their equipment running smoothly for years to come.

Begin with routine inspections to identify any signs of wear or damage. Checking fluid levels, filters, and belts should be part of your regular schedule. Replacing oil and air filters at recommended intervals helps maintain efficiency and protects the engine from debris and contaminants.

Pay special attention to the cooling system. Regularly inspect hoses and connections for leaks, and ensure that the coolant is at the proper level. Overheating can lead to significant damage, so maintaining this system is vital.

Additionally, cleaning the exterior and undercarriage of the machine can prevent rust and buildup that can hinder performance. A thorough wash after each use, especially in harsh conditions, helps preserve the integrity of components.

Lastly, consult the service intervals recommended by the manufacturer for more complex maintenance tasks. Following these guidelines will ensure that your equipment remains reliable and efficient, ultimately leading to a more productive experience.

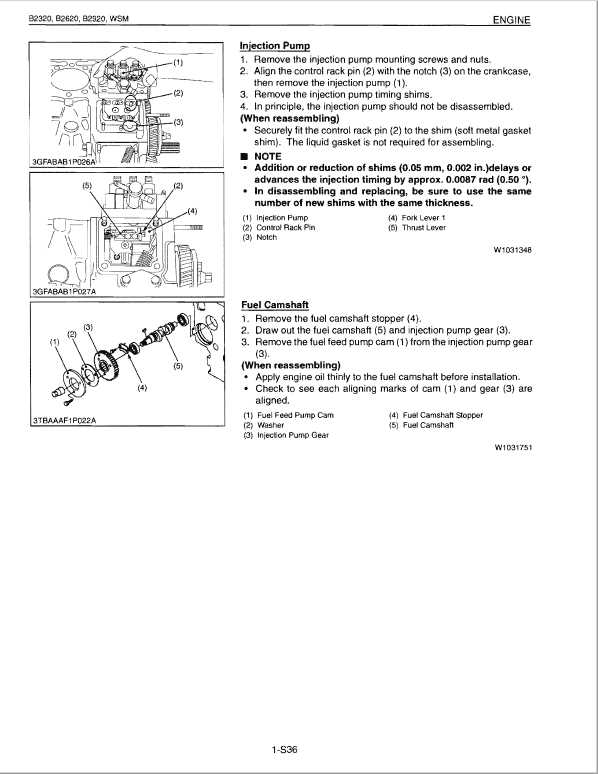

Common Issues and Troubleshooting Guide

This section aims to address typical problems encountered with compact tractors and provide effective solutions. Understanding these common issues can help users maintain their equipment efficiently and minimize downtime.

Frequent Problems and Solutions

| Issue | Possible Causes | Recommended Actions |

|---|---|---|

| Engine Won’t Start | Dead battery, fuel blockage, or faulty ignition | Check battery charge, inspect fuel lines, and test ignition system |

| Overheating | Low coolant level, blocked radiator, or faulty thermostat | Refill coolant, clean radiator, and replace thermostat if necessary |

| Poor Performance | Clogged air filter, dirty fuel injectors, or low tire pressure | Replace air filter, clean injectors, and check tire pressure |

| Hydraulic Issues | Low fluid level, leaks, or worn seals | Top up hydraulic fluid, inspect for leaks, and replace seals as needed |

Maintenance Tips

Regular inspections and preventative maintenance can greatly reduce the likelihood of encountering these issues. Ensure all fluids are topped up, filters are replaced periodically, and any signs of wear are addressed promptly.