Understanding how to operate and maintain your machinery is essential for ensuring optimal performance and longevity. This section aims to provide insightful information that will help you navigate the various features and functionalities of your device, promoting an effective and efficient user experience.

Key considerations will be discussed, focusing on safe handling, routine checks, and troubleshooting common issues. Emphasizing proper care techniques can significantly enhance the reliability of your equipment, ensuring that it serves you well for years to come.

By familiarizing yourself with the recommended practices outlined here, you will gain the confidence needed to utilize your equipment fully. This knowledge not only empowers you as an operator but also contributes to a smoother operational experience.

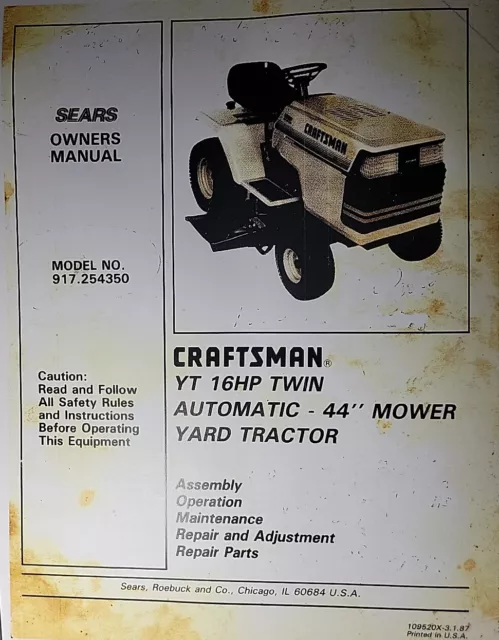

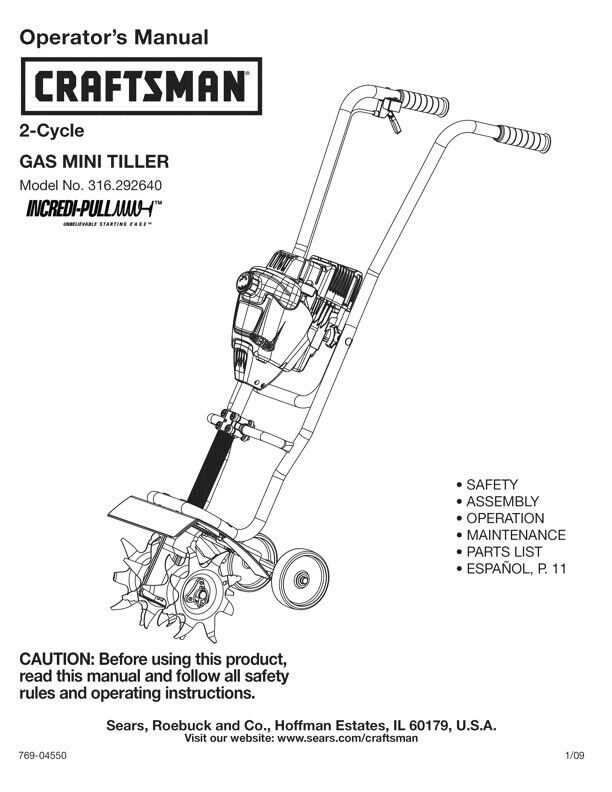

Craftsman T2200 Overview and Features

This section provides a comprehensive look at a specific model, highlighting its capabilities and design elements that make it stand out in its category. The product is engineered for efficiency, combining functionality with user-friendly features, ensuring that it meets the needs of its users effectively.

Key Characteristics

- Powerful engine for enhanced performance

- Compact design for easy maneuverability

- Durable construction ensuring longevity

- Versatile functionality for various applications

User-Friendly Features

- Intuitive controls for effortless operation

- Adjustable settings for customized performance

- Easy maintenance access for convenience

Operating Instructions for Craftsman T2200

This section provides essential guidance for utilizing the equipment effectively and safely. Proper operation ensures optimal performance and longevity, enhancing the user experience. Following these instructions will help you understand the features and functions, allowing for efficient use in various tasks.

Before starting, familiarize yourself with the controls and settings. Ensure that the area is clear of obstacles and that you have all necessary safety gear. Begin by checking fluid levels and ensuring all components are in good condition. When ready, start the engine according to the guidelines provided, and allow it to warm up before engaging in any work.

During operation, maintain a steady pace and be mindful of your surroundings. Avoid sudden movements that could compromise control. If any issues arise, such as unusual noises or changes in performance, stop immediately to assess the situation. Regular maintenance checks are crucial to keep the equipment running smoothly and to prevent potential hazards.

Maintenance Tips for Longevity

Ensuring the durability of your equipment requires consistent care and attention. Implementing proper maintenance practices can significantly enhance performance and extend the lifespan of your device. Regular upkeep not only prevents unexpected failures but also contributes to optimal functionality.

Here are some essential tips to consider for maintaining your equipment:

- Regular Cleaning: Keep the machine free from dirt and debris. Clean the exterior and accessible parts after each use to prevent buildup.

- Check Fluids: Monitor and replenish necessary fluids, such as oil or fuel, to ensure smooth operation. Follow the recommended levels specified in the product guide.

- Inspect Components: Periodically examine critical components for wear and tear. Replace any damaged or worn parts promptly to avoid further issues.

- Sharpen Blades: If applicable, regularly sharpen blades to maintain efficiency and performance. Dull blades can strain the motor and reduce effectiveness.

- Store Properly: When not in use, store the equipment in a dry, secure location to protect it from environmental factors that could cause damage.

- Follow Usage Guidelines: Adhere to the recommended usage instructions to prevent misuse that may lead to premature wear or damage.

By incorporating these maintenance practices into your routine, you can significantly improve the performance and lifespan of your equipment, ensuring it remains reliable for years to come.