Understanding the functionality and upkeep of your machinery is crucial for ensuring optimal performance and longevity. This section delves into essential insights and best practices tailored for users seeking to enhance their experience with their specific models. Whether you’re a seasoned professional or a newcomer, having access to comprehensive information can significantly impact your operational efficiency.

Maintenance plays a vital role in preventing unexpected issues and extending the lifespan of your equipment. Regular inspections, proper cleaning techniques, and timely part replacements are foundational steps that contribute to seamless functionality. By familiarizing yourself with these practices, you can avert common pitfalls and maximize productivity.

Furthermore, understanding the operational parameters of your machinery is essential. Knowing how to utilize various features effectively allows you to harness the full potential of your model, making tasks more manageable and efficient. This guide aims to provide you with the knowledge necessary to navigate the complexities of your equipment confidently.

Essential Features of Ingersoll Rand 185

The model in discussion is renowned for its reliability and efficiency, catering to a variety of industrial needs. Its design encompasses a range of functionalities aimed at enhancing performance while ensuring ease of use for operators.

Robust Build Quality: Crafted with durable materials, this unit is engineered to withstand harsh working environments, providing longevity and dependable service.

Powerful Performance: Equipped with a high-performance engine, it delivers substantial output, making it suitable for demanding tasks that require consistent pressure.

Portability: The compact and lightweight structure allows for easy transportation, enabling users to move it between job sites without hassle.

Low Noise Levels: Designed with sound-dampening technology, this unit operates quietly, minimizing disruption in workplaces where noise reduction is crucial.

Easy Maintenance: The straightforward design facilitates quick access to components for routine checks, ensuring that upkeep is efficient and less time-consuming.

Advanced Controls: Featuring intuitive controls, users can easily monitor and adjust settings, promoting operational efficiency and enhancing user experience.

Overall, this model stands out for its combination of power, portability, and user-friendly features, making it a valuable addition to any industrial toolkit.

Maintenance Guidelines for Optimal Performance

Ensuring peak functionality of your equipment requires a commitment to regular upkeep. Proper maintenance not only enhances the lifespan of the machine but also improves efficiency and reduces the risk of unexpected failures. Adhering to systematic care practices can lead to consistent performance and reliable operation.

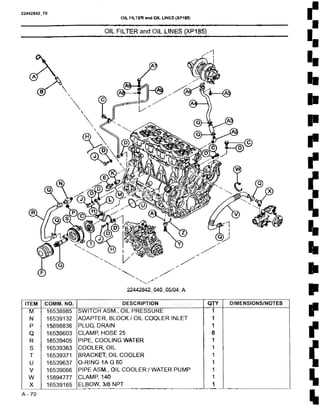

Start by frequently checking and replacing the oil as needed. Clean or change the filters to avoid blockages that could hinder airflow. Inspect the belts for signs of wear and ensure they are properly tensioned to prevent slippage. Additionally, monitoring fluid levels is crucial for optimal operation.

Regularly examining connections and fittings helps identify potential leaks or issues before they escalate. Keeping the unit clean from dust and debris can prevent overheating and promote better performance. Lastly, consult the provided guidelines for recommended service intervals to maintain optimal condition.

Troubleshooting Common Compressor Issues

Understanding how to identify and resolve typical challenges is essential for maintaining optimal functionality in your equipment. This section provides guidance on addressing frequent problems that may arise during operation. By following systematic approaches, users can efficiently diagnose and rectify issues, ensuring continuous performance and longevity.

Performance Drops

When your device shows reduced efficiency, several factors may be at play. Check for air leaks in the connections or hoses, as these can significantly hinder performance. Additionally, inspect the filter for blockages, which can restrict airflow and cause operational issues. Regular maintenance and timely replacements can prevent these performance dips.

Unusual Noises

Strange sounds during operation can indicate underlying problems. Listen for rattling, grinding, or hissing noises, as these may suggest loose components or internal wear. Ensure all parts are securely fastened and consider lubricating moving elements to minimize friction. If the issue persists, further inspection may be necessary to avoid potential damage.