Understanding how to properly operate your machinery is essential for achieving the best results and ensuring longevity. This guide is designed to provide you with clear and concise information on effectively using and maintaining your equipment for optimal performance. With this detailed breakdown, you’ll gain valuable insights that will make your work more efficient and safe.

Maintaining equipment in good condition is critical for ensuring its longevity. Regular care and attention to key components will prevent breakdowns and extend the lifespan of the machinery. In this section, we’ll cover essential practices that you should incorporate into your routine maintenance schedule.

Additionally, safe operation is paramount when handling any heavy-duty equipment. Knowing the correct procedures and following safety recommendations not only protects the user but also improves the overall efficiency of your tasks. By following the guidelines presented here, you can work with confidence, knowing that you’re using the machinery as intended.

Maintenance Overview

Regular upkeep is essential for ensuring optimal performance and longevity of your equipment. This section provides insights into the best practices for maintaining your device, focusing on key areas that require attention. By adhering to a systematic maintenance schedule, users can prevent potential issues and enhance the overall efficiency of their machinery.

Key Maintenance Practices

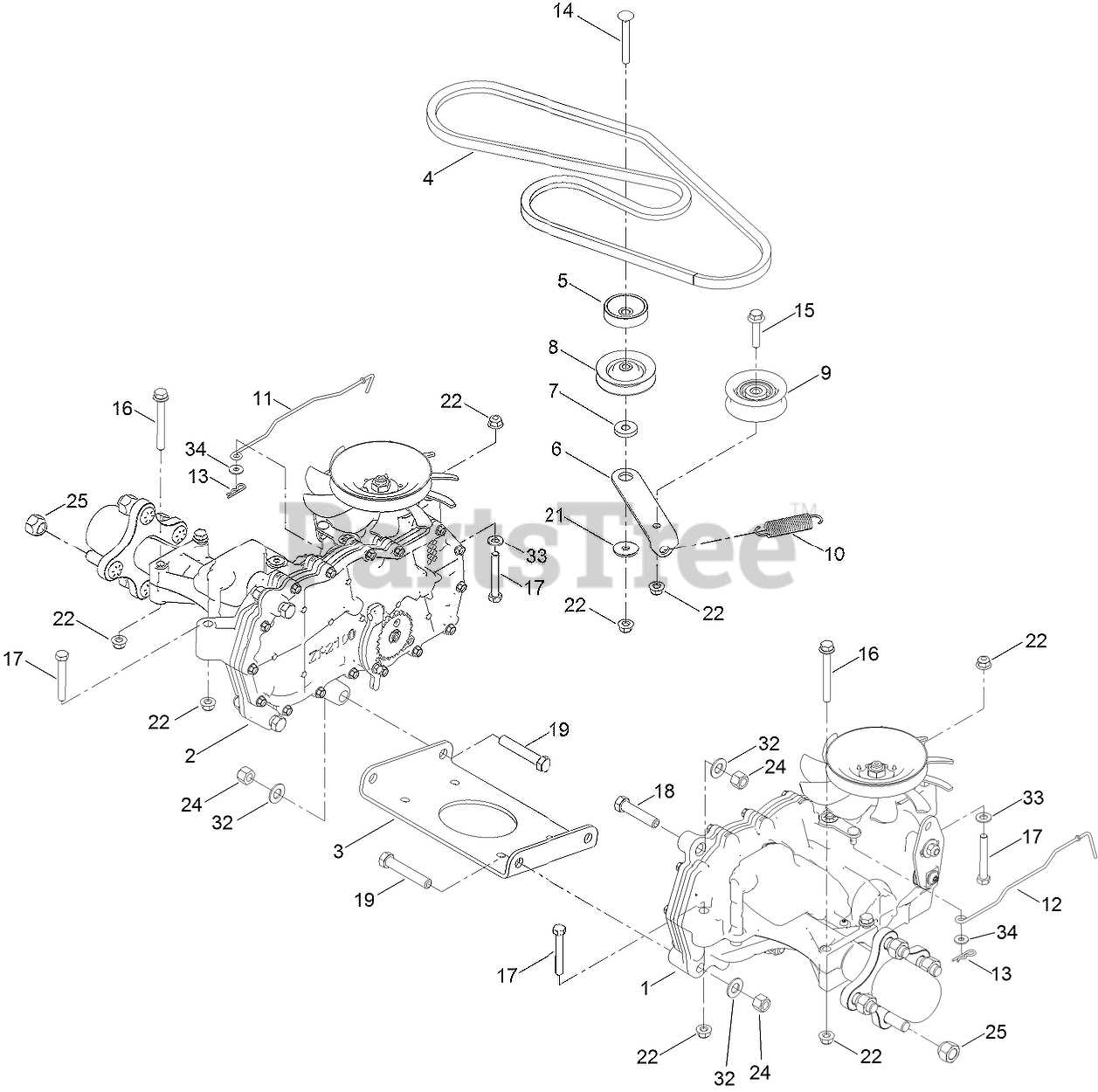

To achieve peak performance, several fundamental maintenance tasks should be routinely performed. These include checking fluid levels, inspecting belts, and ensuring all components are in good working condition. Staying proactive can lead to significant improvements in functionality.

Maintenance Schedule

| Task | Frequency |

|---|---|

| Oil Change | Every 50 hours |

| Air Filter Inspection | Every 25 hours |

| Blade Sharpening | As needed |

| Battery Check | Every 100 hours |

Common Issues and Troubleshooting Tips

When operating outdoor power equipment, users may encounter various challenges that can affect performance and efficiency. Identifying these common problems and implementing effective solutions can enhance the overall experience and prolong the lifespan of the device.

Starting Difficulties: One frequent issue is difficulty starting the machine. This can often be attributed to a drained battery, old fuel, or a clogged air filter. Checking and replacing these components can resolve the problem.

Uneven Cutting: If the equipment produces an uneven cut, it may be due to dull blades or improper height settings. Regular maintenance, including sharpening blades and adjusting cutting heights, can help achieve a uniform appearance.

Overheating: Overheating can lead to operational failures. Ensure that the cooling vents are clear of debris and that the oil levels are adequate. Frequent checks can prevent this issue from becoming serious.

Strange Noises: Unusual sounds during operation can indicate mechanical issues. Inspecting belts, bearings, and other moving parts can help identify the source of the noise and allow for timely repairs.

By addressing these common challenges proactively, users can ensure smoother operation and enjoy the full benefits of their equipment.

Step-by-Step Setup Instructions

This section provides a comprehensive guide to assist you in setting up your equipment efficiently. Following these detailed steps will ensure proper installation and optimal performance.

- Gather Necessary Tools and Materials

- Check the required tools such as wrenches and screwdrivers.

- Prepare all materials needed for the setup process.

- Choose an Appropriate Location

- Select a flat, stable surface to place your device.

- Avoid areas with excessive moisture or direct sunlight.

- Assemble the Main Components

- Refer to the schematic to align parts correctly.

- Secure each piece tightly to ensure stability.

- Connect Power Supply

- Identify the power cord and connect it to a suitable outlet.

- Make sure all connections are secure before proceeding.

- Test the Setup

- Turn on the device and monitor for any issues.

- Ensure all features are functioning as intended.

By adhering to these instructions, you will successfully set up your equipment and be ready for use. Regular maintenance checks are advised to ensure longevity and efficiency.